Suction volume system with improved control and volume adjustment

A technology of suction volume and capacity, applied in the field of exhaust suction volume, can solve the problems such as the complexity of the engine and its electronic control system, and achieve the effects of simplifying the electronic control system, improving the smoothness of suction volume, and high suction volume accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

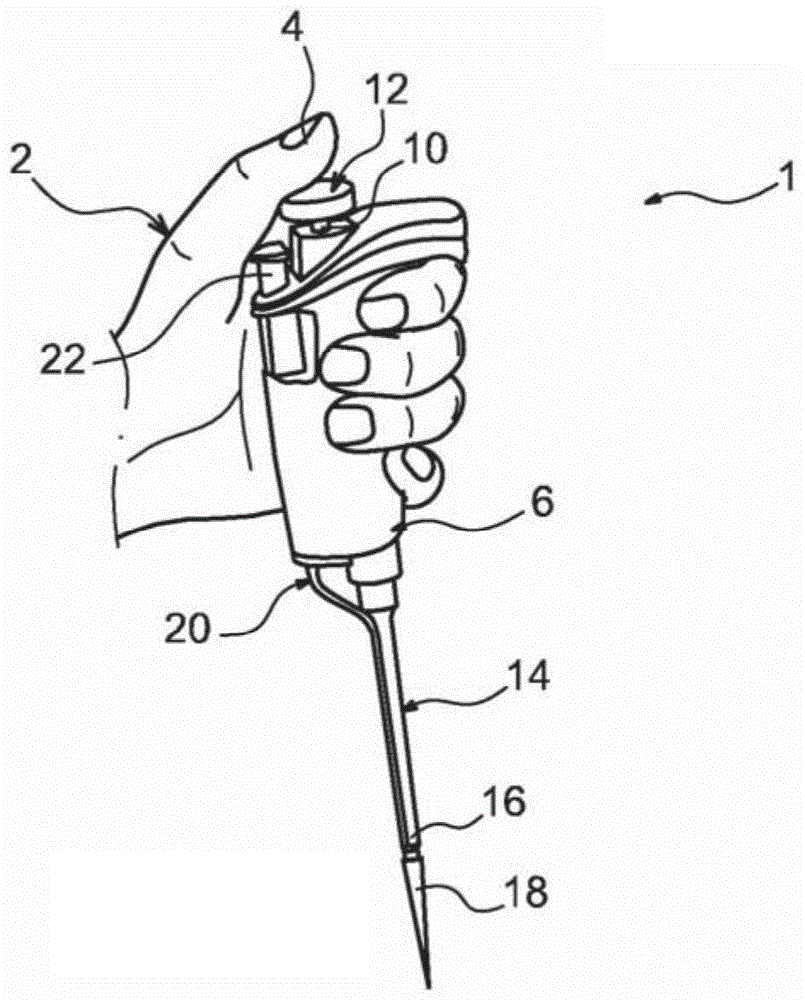

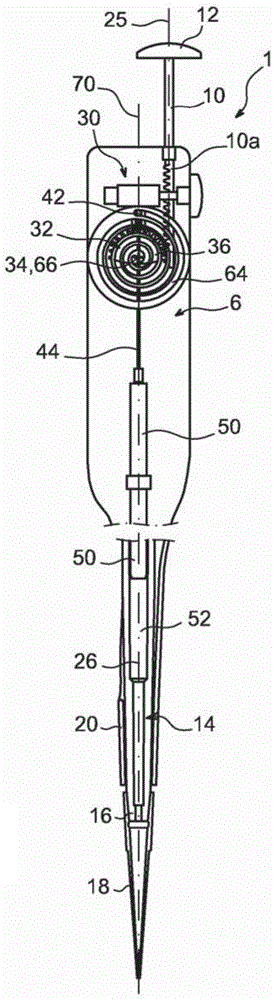

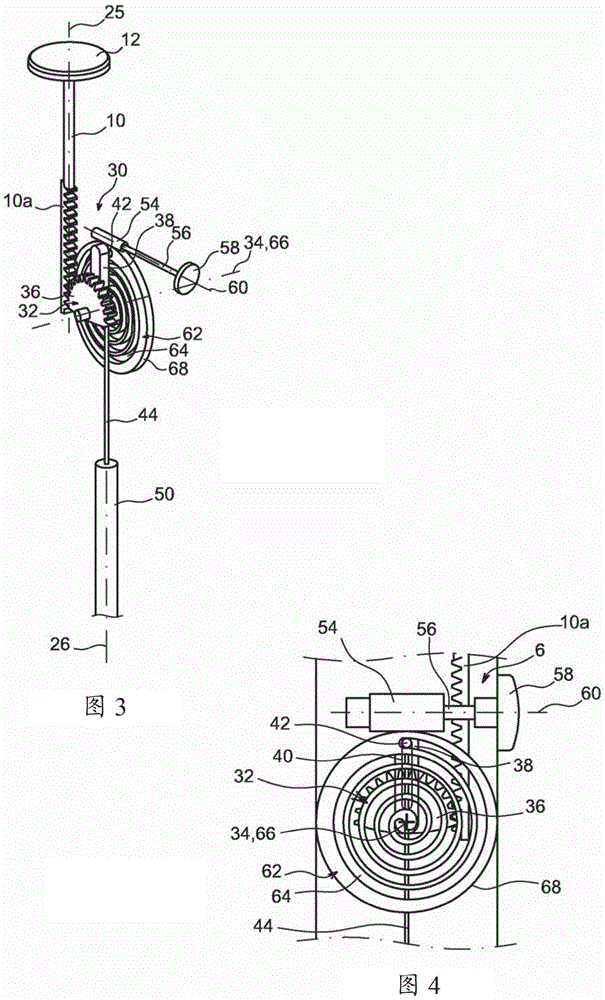

[0038] combine first figure 1 , figure 1 A manually operated exhaust gas sampling pipette 1 of a preferred embodiment of the invention is shown. Throughout the following description, the terms "top" and "bottom" are considered with a pipette held vertically at or near the pipetting position.

[0039] exist figure 1 In , the pipette 1 is shown held by the hand 2 of an operator who (via his / her thumb 4) drives the pipette to dispense liquid that has previously been drawn.

[0040] More precisely, the pipette 1 comprises a handle 6 forming the upper body of the pipette, on the top end of which a rod-shaped suction control element 10 is supported, in the suction position the upper part of the rod-shaped suction control element 10 controls the The knob 12 is intended to withstand the pressure of the operator's thumb. By way of indication, it is noted that a display screen (not shown) may be provided on the handle 6 . Likewise, means for adjusting the volume to be sampled can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com