A kind of threshing and redrying processing method of tobacco leaf raw material

A technology of threshing, redrying, and processing methods, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of small batches, uneven distribution of tobacco raw materials, and many grades of tobacco leaves, so as to ensure uniformity, stability, and stability. Product quality style, the effect of improving the smoothness of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

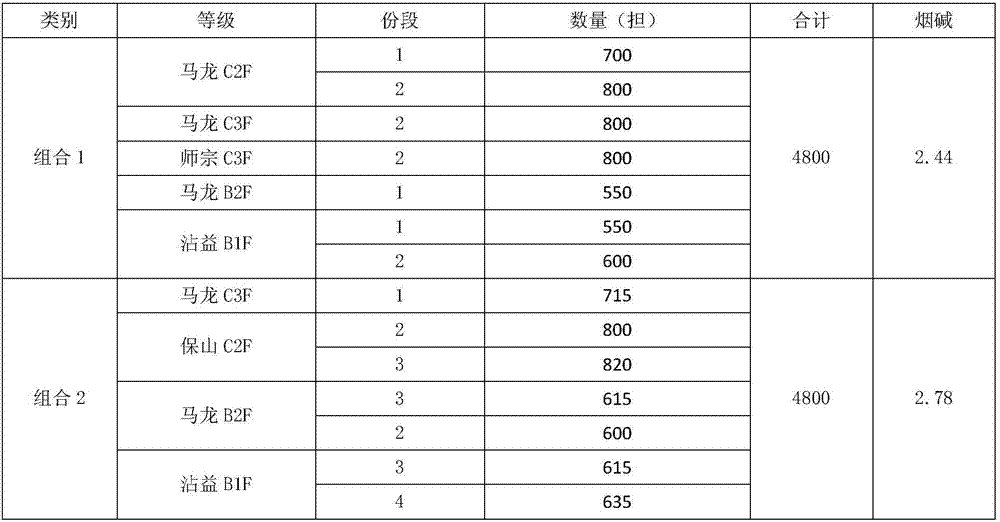

[0020] Example 1: A method for threshing and redrying tobacco leaf raw materials, which is based on the middle tobacco leaves C2F, C3F and upper tobacco leaves B2F planted in Malong County, Yunnan Province, the middle tobacco leaves C3F planted in Shizong County, and the upper tobacco leaves planted in Zhanyi County B1F, the central tobacco leaf C2F grown in Baoshan County is used as the material, and the specific steps are as follows:

[0021] (1) Divide the above-mentioned C2F, C3F of Malong, C3F of Shizong, and C2F of Baoshan into 3 sections from the tip of the leaf, and mark them as 1, 2, 3 respectively, Malong B2F, Zhanyi B1F is also divided into 4 sections starting from the leaf tip, which are marked as 1, 2, 3, and 4 respectively, with a total of 20 specifications. The length of each section of the upper tobacco leaf is 60-70cm, and the length of each section of the middle tobacco leaf is 65-70cm; Pack each segment of tobacco leaves of each grade into frames, and conduc...

Embodiment 2

[0038] Using the central tobacco leaves C2F and C3F planted in Nanyang, Henan, the central tobacco leaves C2F planted in Nanxiong, Guangdong, and the central tobacco C2F planted in Chenzhou, Hunan, 4800 dan each, a total of 4 grades were divided into 3 parts from the tip of the leaves, and respectively Marked as 1, 2, 3, the above materials are the middle tobacco leaves, each section length is 65-70cm; each section of tobacco leaves of each grade is divided into frames, and nicotine determination and sensory evaluation are carried out for each specification , and weighed the weight of tobacco leaves of each specification, the specific nicotine content and evaluation results are shown in Table 3:

[0039] Table 3 Smoking evaluation and nicotine detection after each grade segment

[0040]

[0041]

[0042] Through the above analysis, it is found that the tobacco leaves of the third section of Nanyang C2F, the first and third sections of Nanyang C3F, the third section of Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com