Filtering system

A filter system and filter medium technology, applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of flexible configuration of filter medium, low filtration efficiency, limited filtration precision, etc., and extend the interval between screen changes The effect of time, no melt leakage, and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

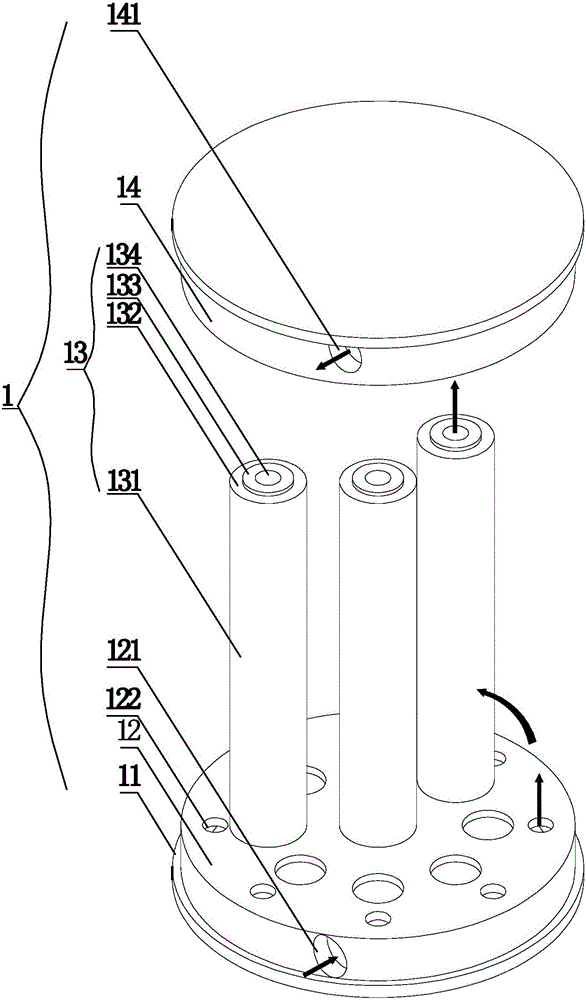

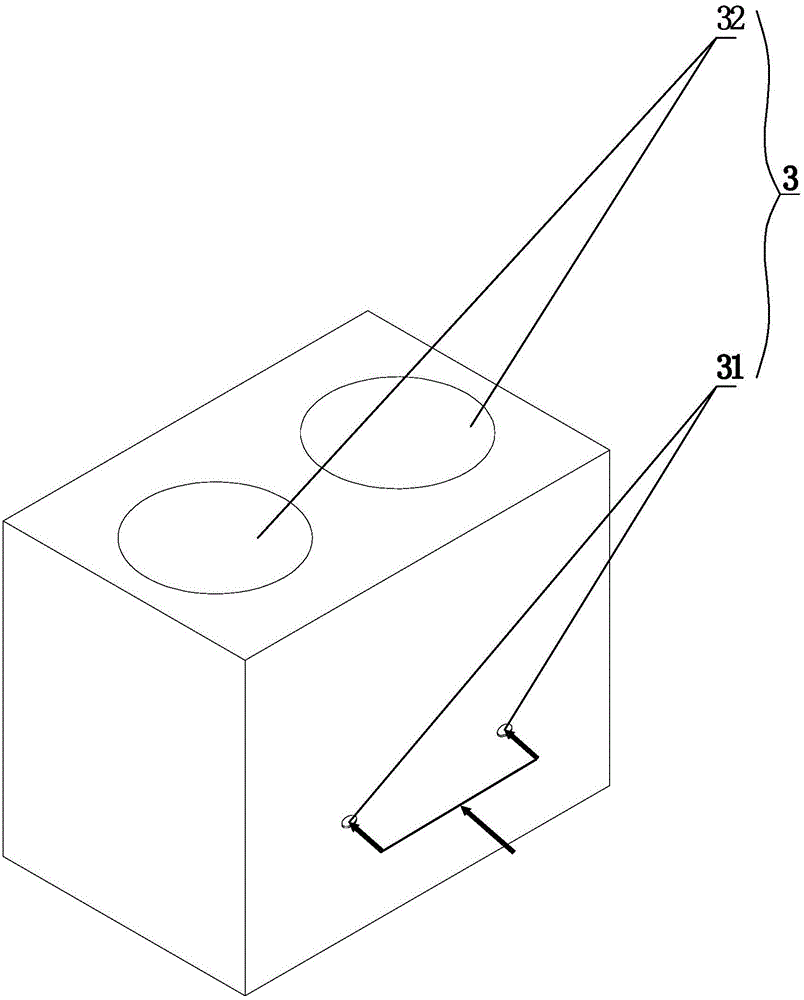

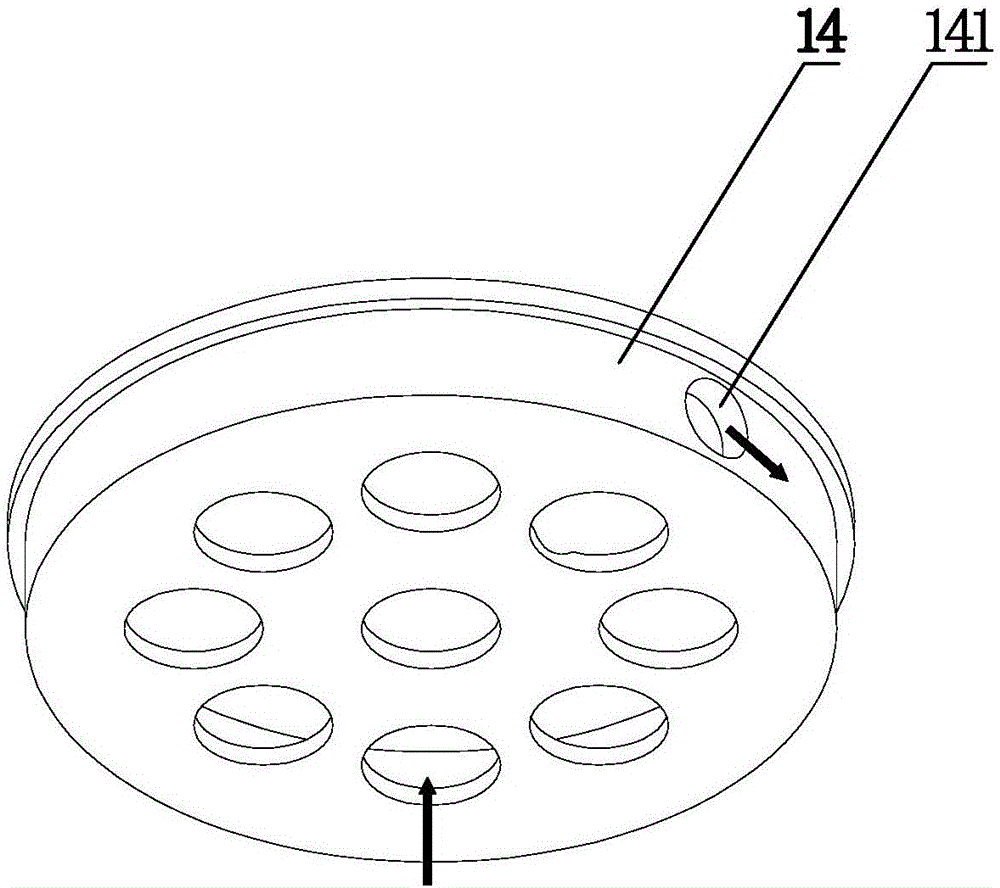

[0033] This embodiment is a filter system, which is composed of three parts: a filter core type melt filter 1, a recoil type washing screen changer 2, and a booster pump. Type melt filter 1 is connected, combined with figure 1 , the cartridge type melt filter 1 is composed of a fixed plate 11, a lower cover 12, a filter element 13, an upper cover 14 and an outer cylinder 4, the filter element 13 is installed between the upper cover 12 and the lower cover 14, combined Figure 4, the outer cylinder 4 is set on the filter element 13 between the upper cover plate 12 and the lower cover plate 14, the lower part of the lower cover plate 12 is fixed by the fixing plate 11, and the side wall of the lower cover plate 12 is provided with a melt inlet 121, The top is provided with a plurality of diversion ports 122 on the periphery of the filter element 13, and each diversion port 122 is connected with the melt inlet 121 in the lower cover plate 12; the filter element 13 is composed of a...

Embodiment 2

[0040] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: a layer of heating plate 27 is arranged on the outer wall of the screen changer cavity 26; there is one hydraulic cylinder 28, and the hydraulic cylinder 28 is provided with two position rods , each position rod 281 corresponds to a plunger 21 . The setting of the heating plate 27 ensures that the melt maintains a constant temperature during conveying and filtering, and the same hydraulic cylinder 28 can control the states of the two plungers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com