Horn magnetic circuit assembly glue injection clamp

A horn magnetic circuit and fixture technology, which is applied to coatings, devices for coating liquid on surfaces, etc., can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, simple overall structure, and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

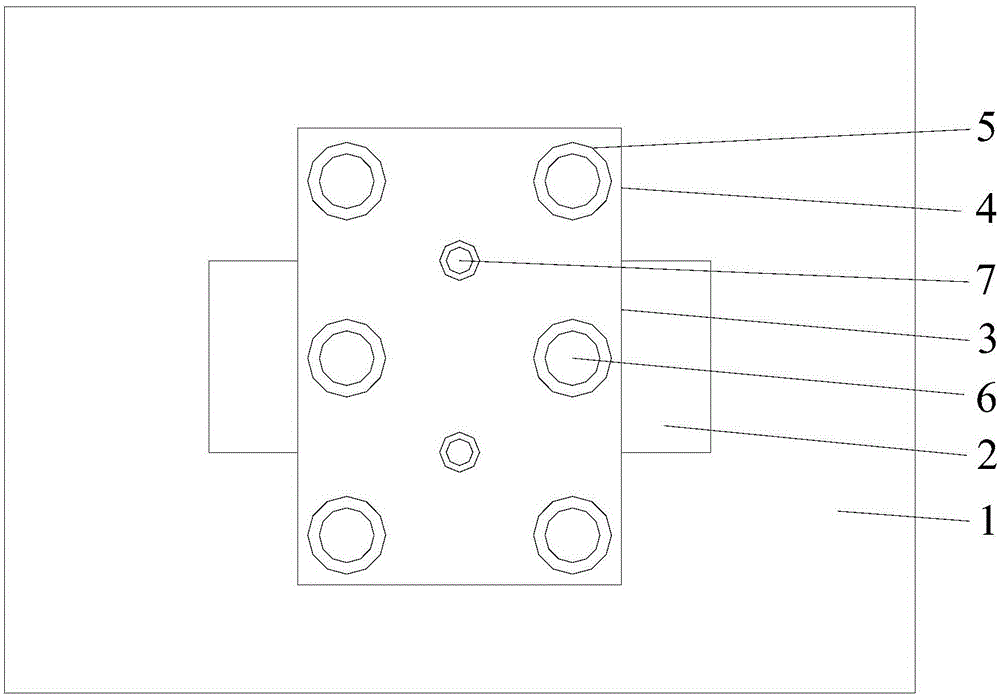

[0013] Please refer to figure 1 , the horn magnetic circuit assembly glue injection jig includes a base plate 1, a pair of clamping blocks 2 are arranged on the upper surface of the base plate 1, and a limiting groove 3 is formed between the pair of clamping blocks 2, and the limiting groove 3 is provided with There is a fixture main body 4, the fixture main body 4 is fixed on the substrate 1, and the upper surface of the fixture main body 4 protrudes upwards with six protrusions 5, and the six protrusions 5 are arranged in three rows and two columns , the top surface of each protruding portion 5 is recessed to form a clamping groove 6 adapted to the shape of the magnetic circuit assembly. Specifically, the clamp block 2 and the clamp body 4 are cuboid structures, the long sides of the clamp block 2 are parallel to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com