A kind of silk grinding machine and silk grinding method

A technology of a wire grazing machine and a wire feeding mechanism, which is applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using tools, etc., and can solve problems such as unsightly molding, poor wire feeding of welding wire 03, and pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

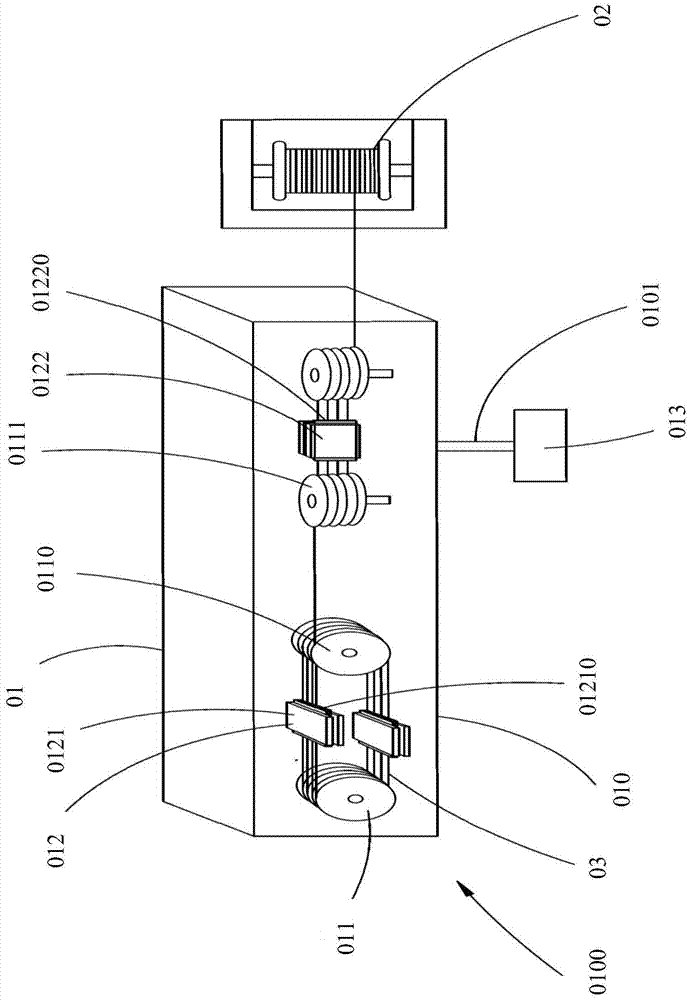

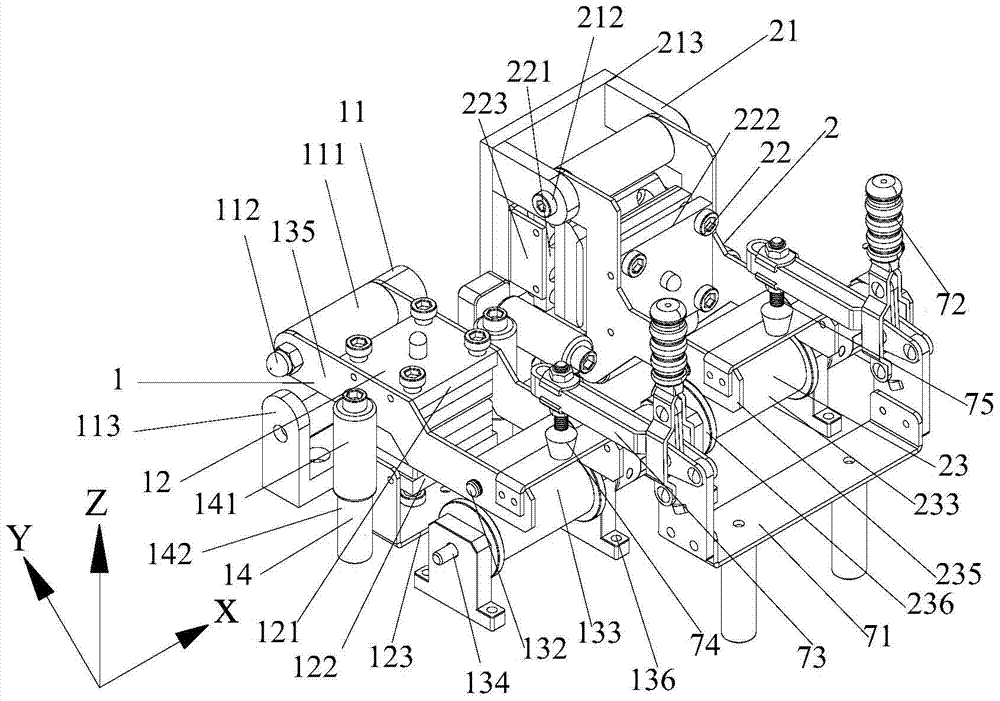

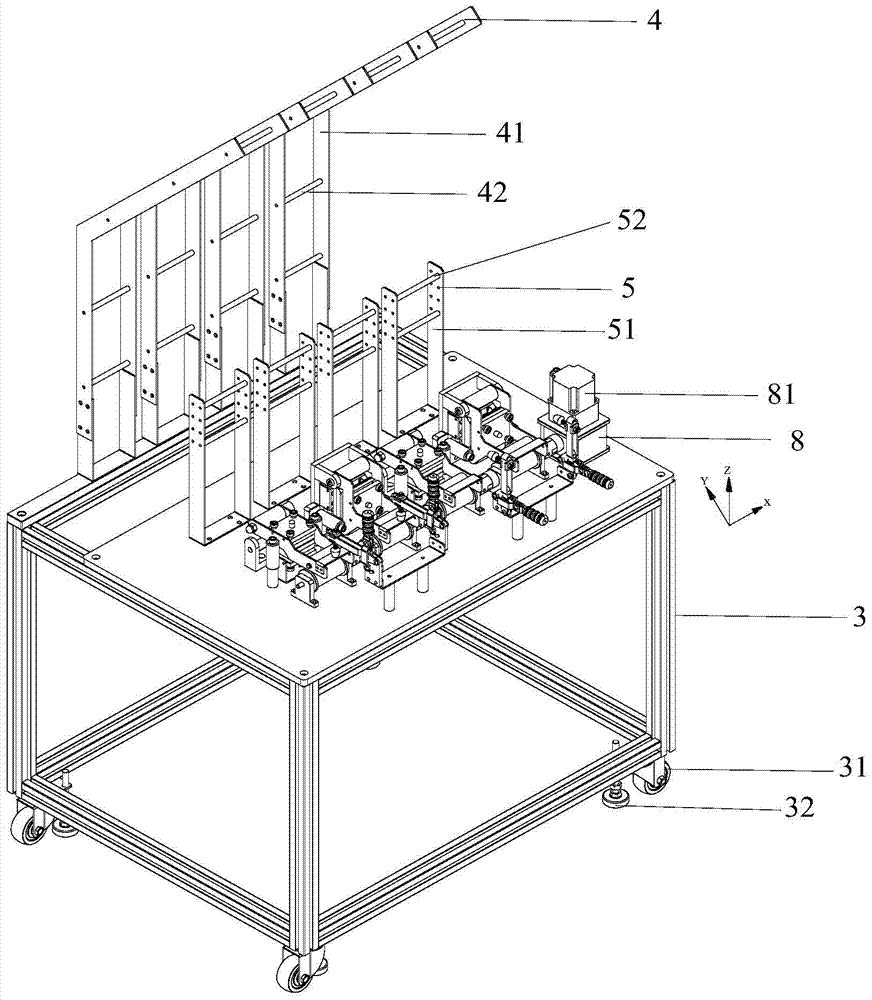

[0037] Please refer to image 3 , a kind of silk grating machine provided by the present invention is located on the frame 3, and includes several groups of grating device groups arranged in the first horizontal line, with the first horizontal line as the X axis, on the frame 3 table, with vertical The straight line on the first horizontal line is the Y axis, and a three-dimensional coordinate system including the X axis, Y axis, and Z axis is established with the vertical upward direction as the positive direction of the Z axis, and the XY plane is the table top of the rack 3. Please continue to refer to image 3 , the frame 3 includes two sets of grating device groups and arranged along the X-axis direction, each group of grating device groups includes two grating devices, also arranged along the X-axis direction, respectively horizontal grating device Device 1 and vertical grating device 2.

[0038] Preferably, in order to facilitate movement, the frame 3 is in the shape ...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that among the two grating device groups, one grating device group is composed of two identical horizontal grating devices 1, and the other grating device group is composed of two identical vertical grating devices. The device 2 is composed, and the wiping effect of the welding wire 03 in the second embodiment is the same as that in the first embodiment.

Embodiment 3

[0071]The difference between this embodiment and Embodiment 1 is that, among the two grating device groups, the horizontal grating device 1 and the vertical grating device 2 of one grating device group are the same as those in Embodiment 1, and they are all arranged in the X-axis direction , please refer to Figure 10 , wherein the wiping direction of the welding wire 03 is the X-axis direction. The horizontal wiping mechanism 12 and the vertical wiping mechanism 22 of another wire wiping device group are arranged on a straight line forming an acute or obtuse angle with the X-axis direction, then another wire wiping device group will wipe the welding wire 03 as follows: Figure 11 As shown, the wiping direction of the welding wire 03 at this time is the direction of an acute angle or an obtuse angle with the X-axis direction, and the direction of an acute or obtuse angle with the Z-axis direction, so wiping the welding wire 03 from multiple directions in this way makes the wip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com