Rapid robotic imitation learning of force-torque tasks

A robot and robot system technology, applied in the direction of robots, instruments, manipulators, etc., can solve problems such as unsatisfactory static calculation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

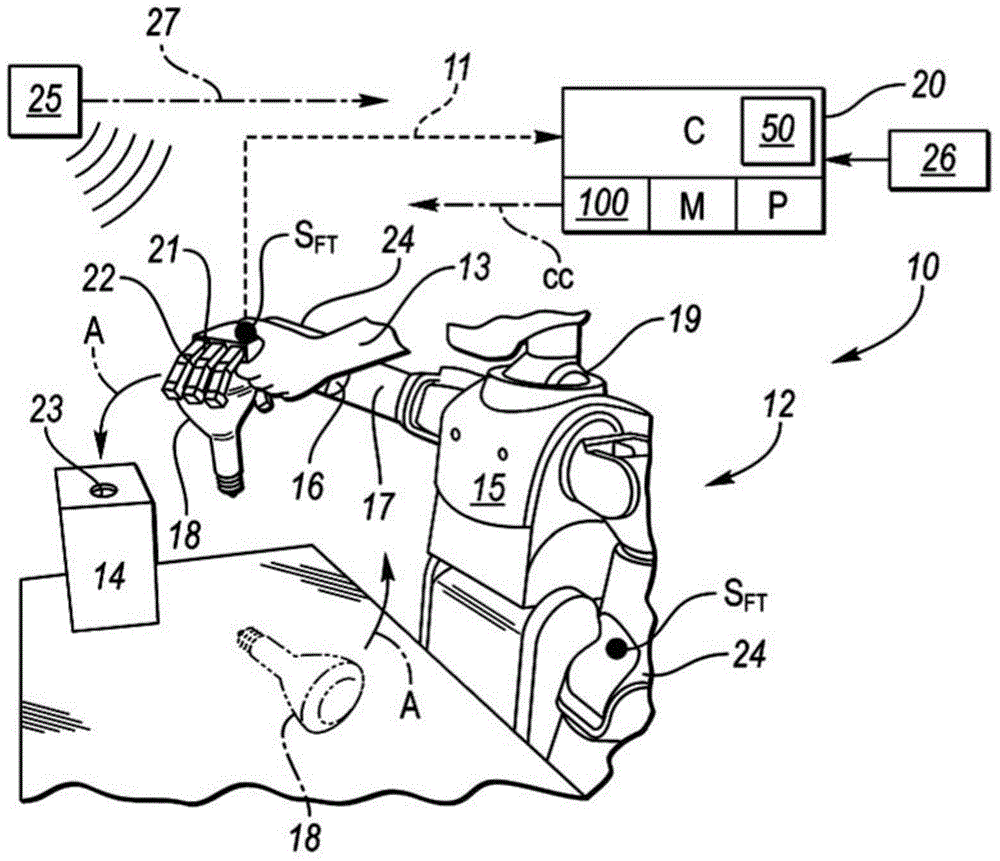

[0024] Referring to the drawings, in which like reference numerals designate like or similar parts throughout the several views, in figure 1 An exemplary robotic system 10 is shown in FIG. The robotic system 10 includes a robot 12 and a controller (C) 20 programmed to perform the method 100 and thereby train the robot 12 to perform a force-torque task via human-assisted task demonstration. Robot 12 may include a torso 15 , an arm 16 having an end effector 21 , and possibly, in an exemplary anthropomorphic embodiment, a head 19 . End effector 21 may be configured as any suitable device for performing the exemplary task, such as a grasper or an anthropomorphic hand with fingers 22 attached to wrist 24 or other arm segment 17, as shown. Fingers 22 in such embodiments may be motorized fingers, extensions, or other grippers.

[0025] A non-limiting exemplary force-torque work task (used below for simplicity and consistency) is the grasping of an object 18 in the form of a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com