Modified resorcinol formaldehyde resin adhesion promoter and preparation method thereof

A technology of resorcinol formaldehyde resin and adhesion promoter, applied in the application of rubber composition, the field of preparation of resorcinol formaldehyde resin adhesion promoter, can solve the problem of high energy consumption, long time, Long response cycle and other issues, to achieve the effect of energy saving and emission reduction production, green production, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

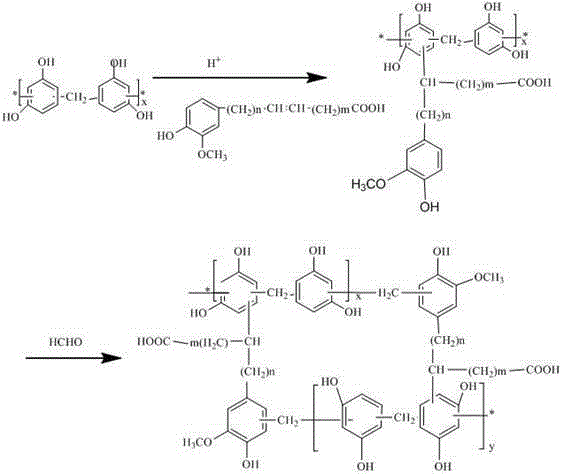

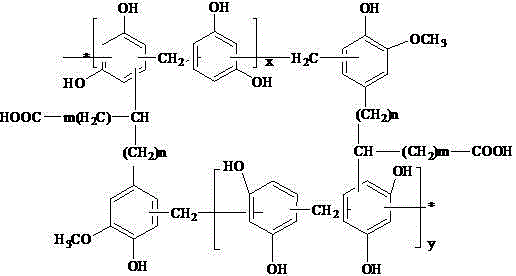

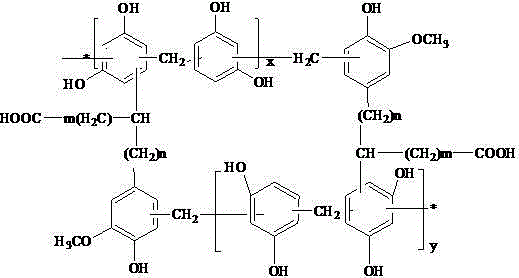

Method used

Image

Examples

Embodiment 1

[0037] (1) Put 100g of resorcinol formaldehyde resin in a 500ml reaction kettle equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, heat and melt it into a liquid; add 0.2g of p-toluenesulfonic acid and mix well;

[0038] (2) Raise the temperature of the reactor to 140°C, and add 2 g of ferulic acid dropwise to the above mixed solution for 20-30 minutes, and continue to react the materials in the reactor for 1 hour with constant stirring;

[0039] (3) Slowly add 3 g of formaldehyde solution with a mass percentage concentration of 37% dropwise under stirring, and react for 0.5 hours;

[0040] (4) Add NaOH with a mass percentage concentration of 10% to the above mixed solution to neutralize the acidic catalyst, so that the Ph is about 7;

[0041] (5) Atmospheric pressure distillation, vacuum dehydration, devolatilization, and then pour out the viscous liquid in the reaction kettle to obtain a resorcinol-formaldehyde resin adhesion promote...

Embodiment 2

[0043] (1) Put 100g of resorcinol formaldehyde resin in a 500ml reaction kettle equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, heat and melt it into a liquid; add 0.3g of dimethylbenzenesulfonic acid and mix Uniform;

[0044] (2) Raise the temperature of the reactor to 140°C, and add 5 g of ferulic acid dropwise to the above mixed solution for 20-30 minutes, and continue to react in the reactor for 1.5 hours with constant stirring;

[0045] (3) Slowly add 3 g of formaldehyde solution with a mass percentage concentration of 37% dropwise under stirring, and react for 0.5 hours;

[0046] (4) Add NaOH with a mass percentage concentration of 10% to the above mixed solution to neutralize the acidic catalyst, so that the Ph is about 7;

[0047] (5) Atmospheric pressure distillation, vacuum dehydration, devolatilization, and then pour out the viscous liquid in the reaction kettle to obtain a resorcinol-formaldehyde resin adhesion promoter...

Embodiment 3

[0049] (1) Put 100g of resorcinol formaldehyde resin in a 500ml reaction kettle equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, heat and melt it into a liquid; add 0.5g of hydrochloric acid and mix well;

[0050](2) Raise the temperature of the reactor to 140°C, and add 7 g of vanillic acid dropwise to the above mixture for 20-30 minutes, and continue to react in the reactor for 2 hours with constant stirring;

[0051] (3) Slowly add 4 g of formaldehyde solution with a mass percentage concentration of 37% dropwise under stirring, and react for 0.5 hours;

[0052] (4) Add NaOH with a mass percentage concentration of 10% to the above mixed solution to neutralize the acidic catalyst, so that the Ph is about 7;

[0053] (5) Atmospheric distillation, vacuum dehydration and removal of other substances, and then pour out the viscous liquid in the reaction kettle to obtain a resorcinol-formaldehyde resin adhesion promoter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com