Sealed transmission structure of drum-type cleaning device

A cleaning device and transmission structure technology, applied in washing devices, other washing machines, textiles and paper making, etc., can solve problems such as poor sealing, achieve high reliability, wide application prospects, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

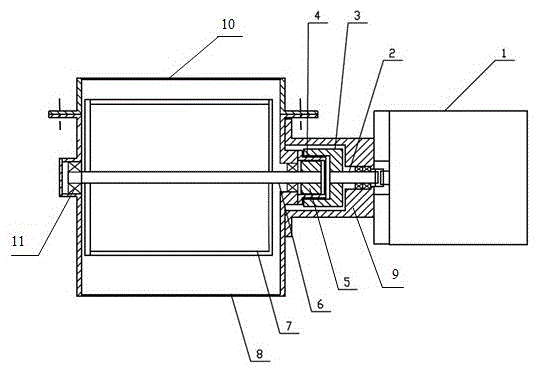

[0021] Such as figure 1 As shown, a sealed transmission structure of a drum type cleaning device includes an outer cylinder 8 with a cylinder cover 10, an inner shaft 6 is connected to the middle of the bottom of the outer cylinder 8 through a bearing 11, and an inner cylinder 7 is fixed on the inner shaft 6. ; outside the mouth of the outer tube 8 is connected with a mounting seat 9 with a stepped hole inside, the outer shaft 2 passes through the stepped hole of the mounting seat 9 and is connected to the mounting seat 9 through a bearing 11, and the motor 1 is connected to the outer shaft 2 is connected and fixed on the outer surface of the mounting base 9, and one end of the inner shaft 6 is connected with a magnetic coupling nested in the stepped hole of the mounting base 9; the magnetic coupling includes a magnetic coupling fixed on the inner sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap