Install door lock without screws

A door lock and door hook technology, which is applied in the field of electrical equipment door locks, can solve problems such as easy rusting of screws, time-consuming and labor-intensive door locks, and corrosion of washing machine panel holes, so as to prevent vibration from falling off and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

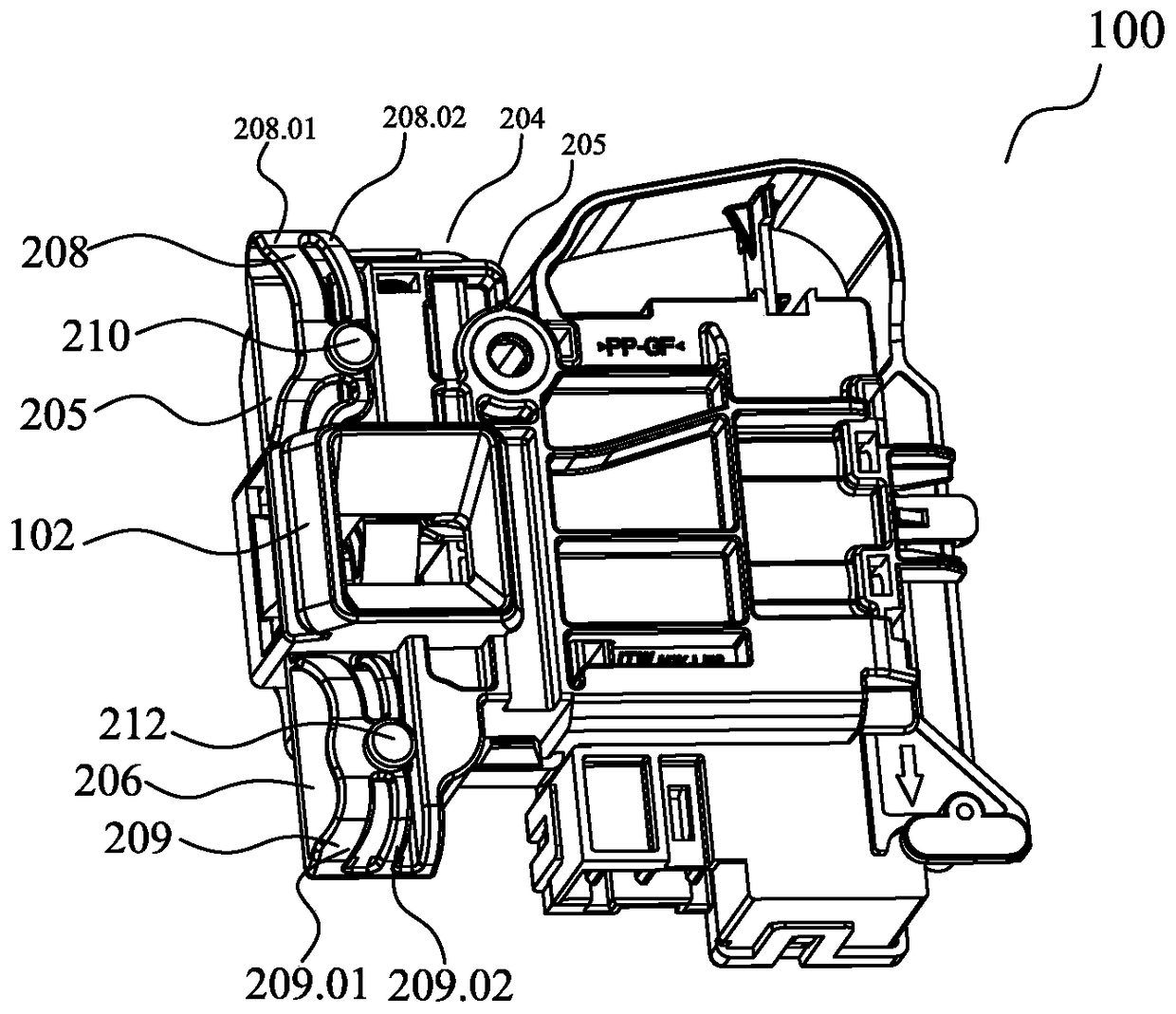

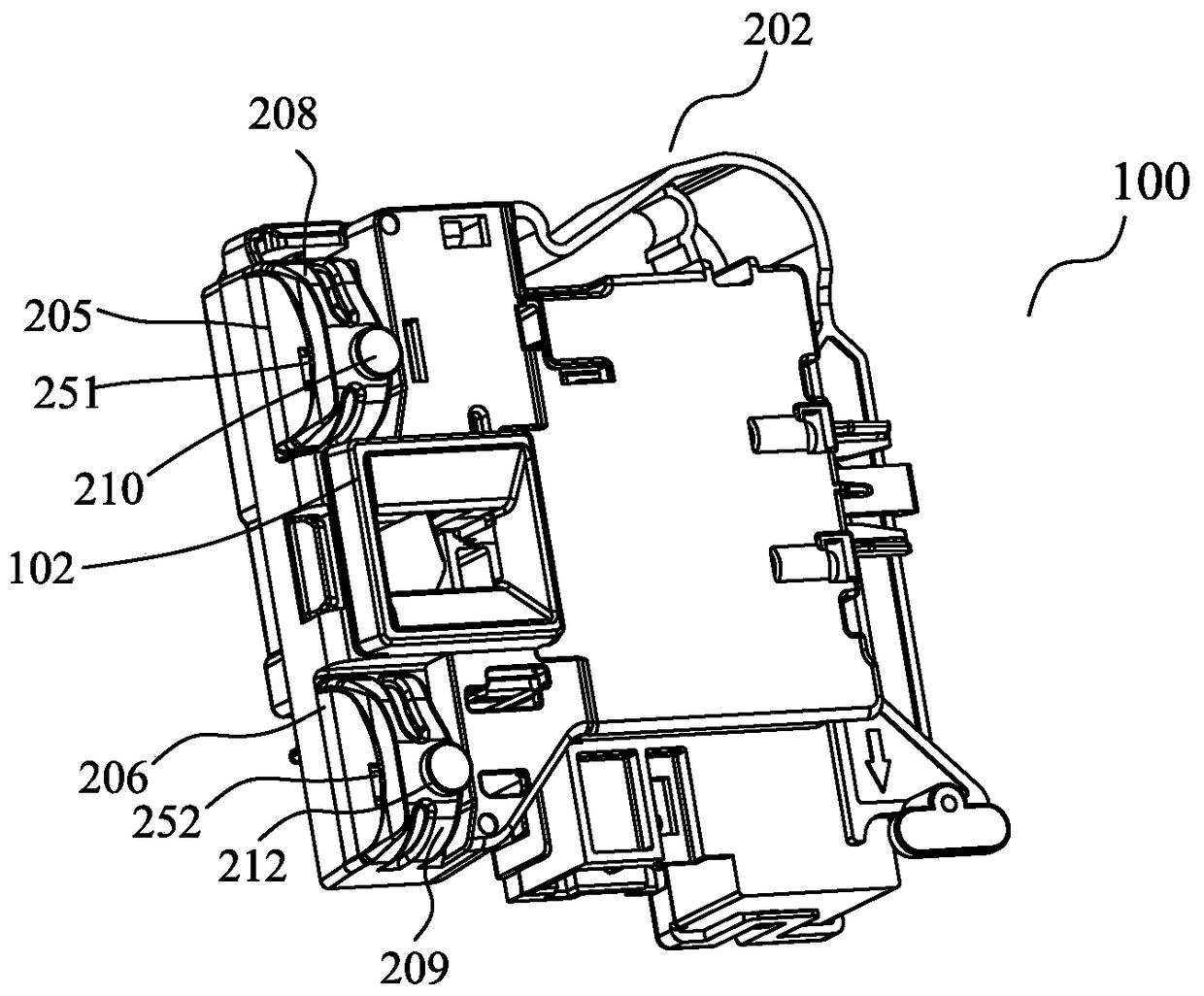

[0044] Various embodiments of the invention will be described below with reference to the accompanying drawings, which form a part hereof. It should be understood that although directional terms such as "front", "rear", "upper", "lower", "left", "right", "perpendicular", or "parallel" are used in the present invention Various example structural parts and elements of the present invention are described, but these terms are used herein for explanatory purposes only, based on the example orientations shown in the drawings. Since the disclosed embodiments of the present invention may be arranged in different orientations, these directional terms are for illustration only and should not be viewed as limiting. In the following drawings, the same reference numerals are used for the same components, and the similar reference numerals are used for similar components to avoid repeated descriptions.

[0045] figure 1 A schematic diagram of the position of the present invention installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com