a waste incinerator

A waste incinerator and furnace body technology, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve the problems of air pollution, harm to human health, black smoke and harmful gases, etc., to increase fresh charge, reduce emissions, The effect of improving combustion efficiency and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

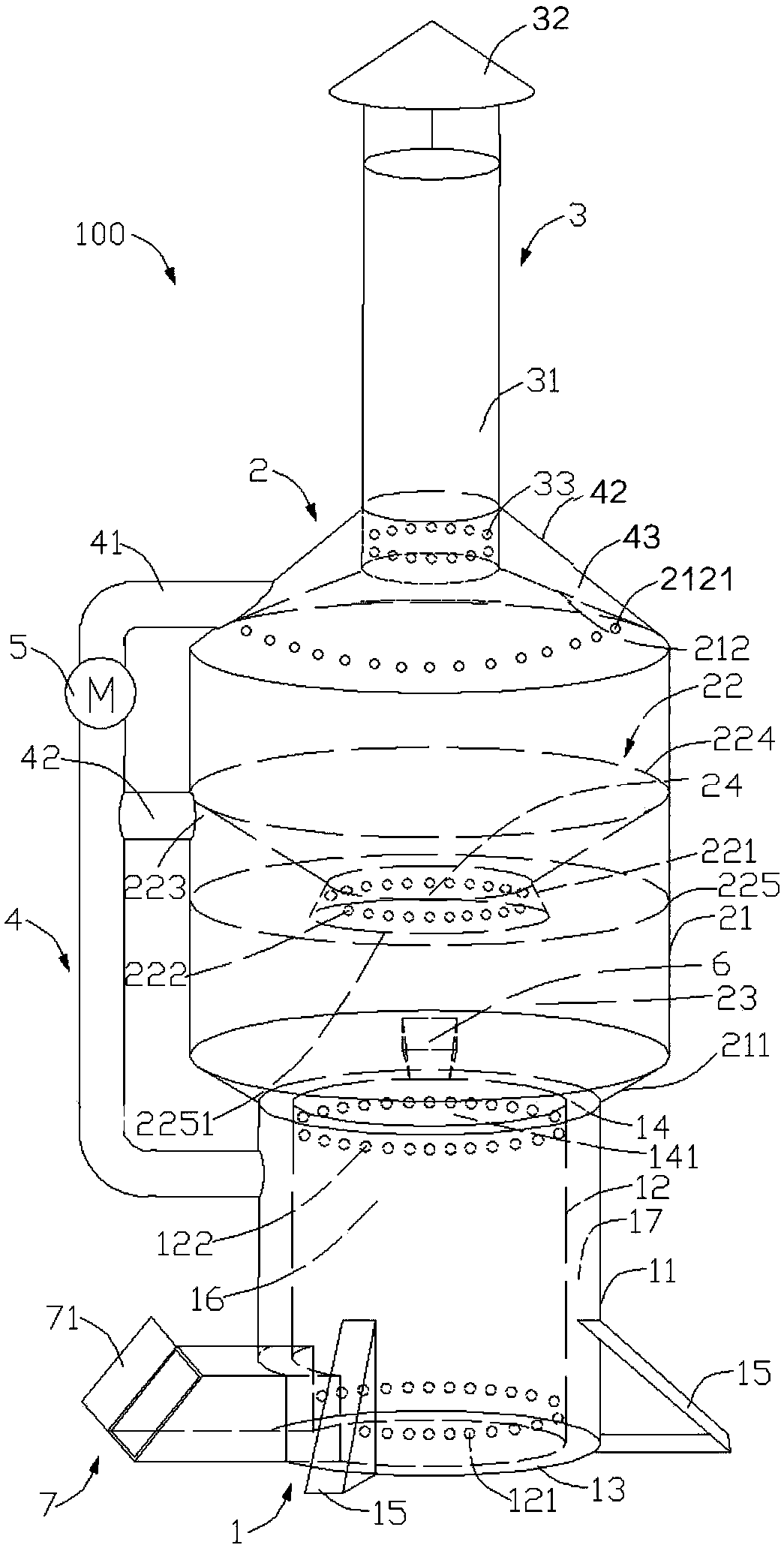

[0021] see figure 1 , in a preferred embodiment of the present invention, a garbage incinerator 100 includes a first furnace body 1, a second furnace body 2, a smoke exhaust pipe 3, an air induction part 4 and a blower fan 5, and set A feeding port 6 and a row of slag ports 7 are provided.

[0022] The first furnace body 1 includes an outer cylinder 11 , an inner cylinder 12 , a bottom plate 13 , a hollow seal 14 and three support frames 15 . The lower part of the side wall of the inner cylinder 12 is provided with a circle of first air inlet holes 121 , and the upper part is provided with a circle of second air inlet holes 122 . The bottom plate 13 is disposed on the bottom of the outer cylinder 11 and the inner cylinder 12 , and the hollow sealing member 14 is provided with a through hole 141 to connect the tops of the inner cylinder 12 and the outer cylinder 11 . Inside the inner cylinder 12 is a first combustion chamber 16 ; the outer cylinder 11 , the inner cylinder 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com