Rotary encoder

A rotary encoder, encoder technology, applied in electrical components, electrical switches, circuits, etc., to achieve the effect of miniaturization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

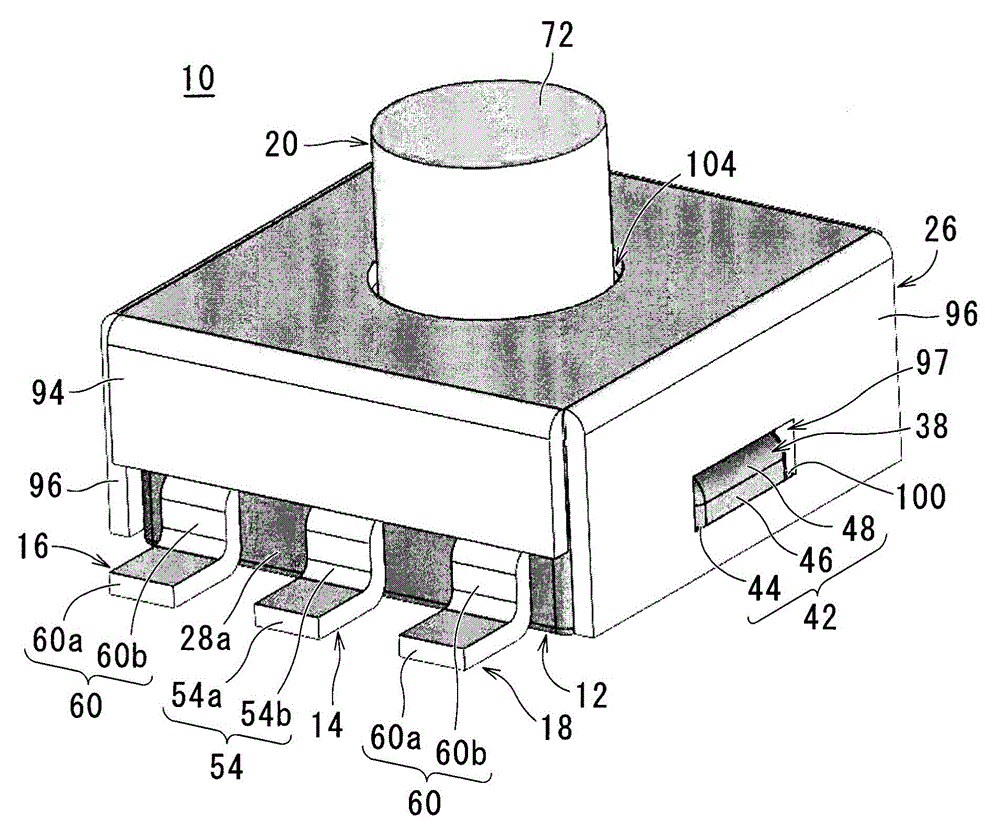

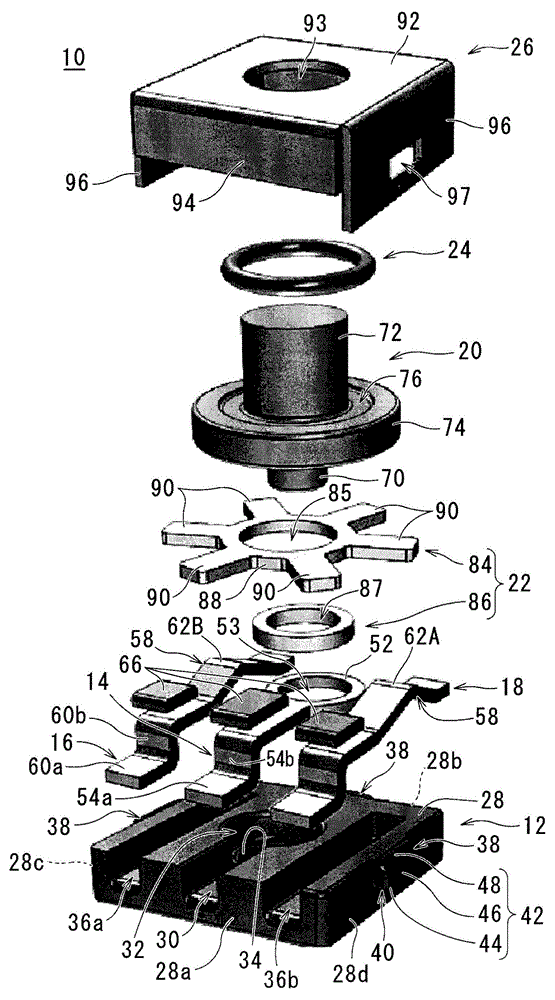

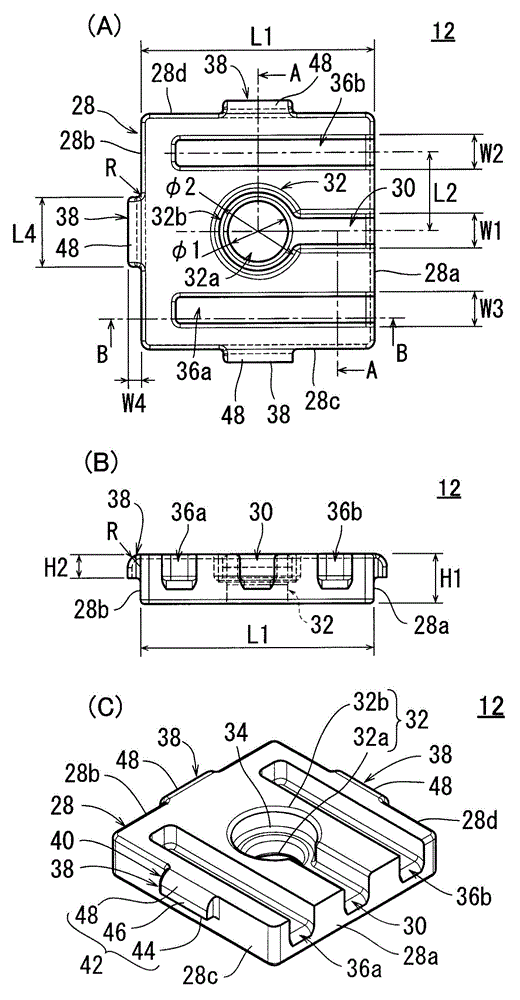

[0048] figure 1 It is a perspective view showing an example of an embodiment of the rotary encoder according to the present invention, figure 2 yes figure 1 exploded perspective view.

[0049] Such as figure 1 , figure 2 , Figure 11 , Figure 13 etc., for example, the rotary encoder 10 according to this embodiment mainly includes: a base member 12; a first fixed contact member 14 arranged on one main surface side of the base member 12; The second fixed contact members 16 and 18 on both sides of the fixed contact member 14; the rotor member 20 rotatably supported on one main surface side of the base member 12; The rotary contact member 22 in contact with the first fixed contact member 14; the compression member 24 arranged on the other end side in the axial direction of the rotor member 20; The rotary contact member 22 , the rotor member 20 , and the compression member 24 are attached to the cover member 26 of the base member 12 in a state of being sandwiched between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com