Strain insulator exchange tool

A technology of tensile insulators and tools, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient electricity consumption, adverse effects on economic and social benefits of enterprises, institutions and residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below:

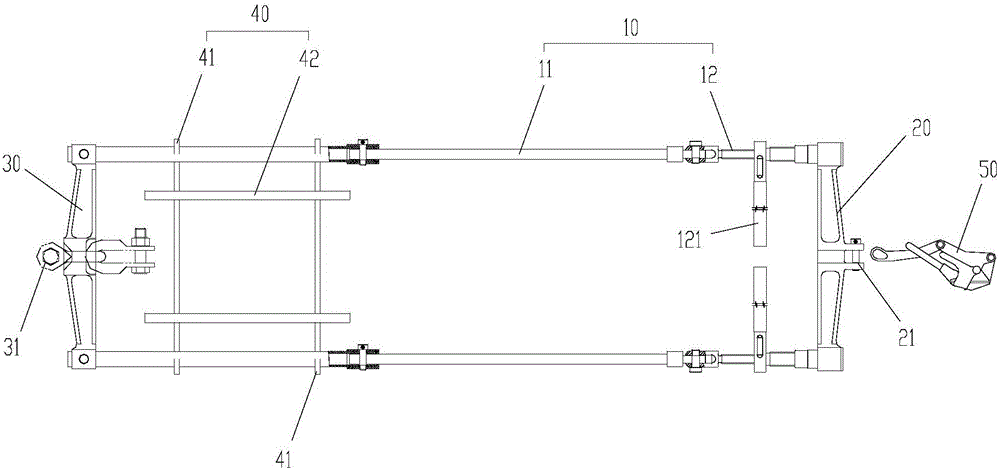

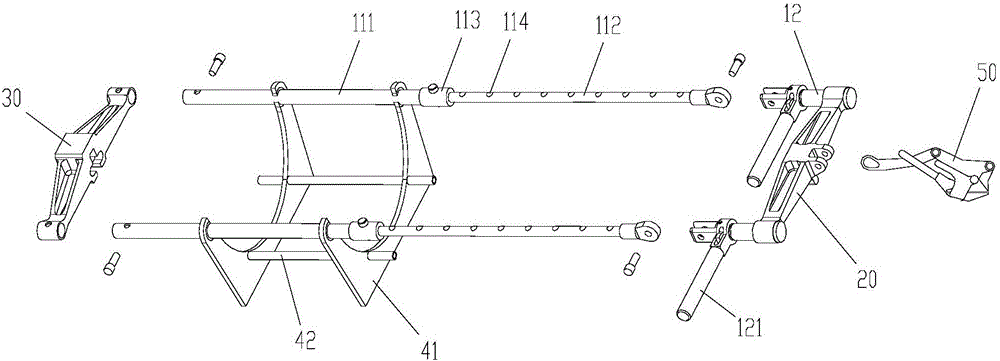

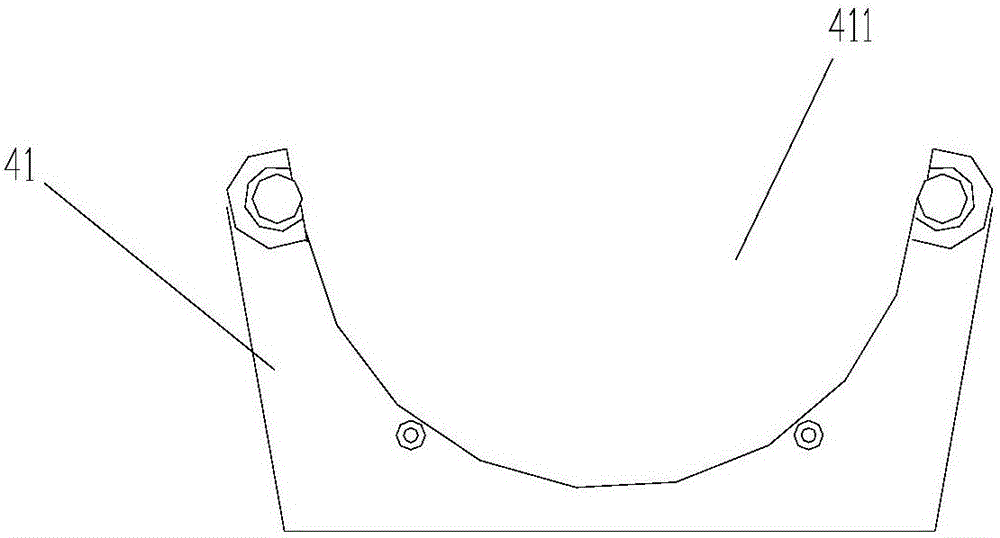

[0022] Such as Figure 1-3 As shown, it is a strain insulator replacement tool, which includes a first insulating end plate 20, a second insulating end plate 30, a wire gripper 50, two clamping plates 41 and two telescopic insulating pull rods 10 (the clamping plates 41 and the number of insulating pull rods 10 can be set according to the actual situation), the insulating pull rod 10 is provided with a control handle 121 for controlling expansion and contraction; the first insulating end plate 20 and the second insulating end plate 30 are respectively arranged on two end, together with two insulating pull rods 10 to form an insulating tensioning frame; the clamping plate 41 is erected on the two insulating pulling rods 10, on which there is a concave arc-shaped gap 411 for supporting the tension insulator, and two adjacent clamping plates A connecting rod 42 is pierced between the plates 41, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com