A fast detection device for a dust shield and its working method

A technology of detection device and dust shield, which is applied to measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of reduced product qualification rate, low efficiency, low measurement efficiency, etc., and achieves improved measurement efficiency and simple operation and measurement. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

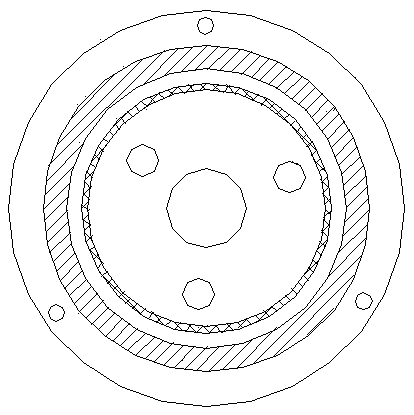

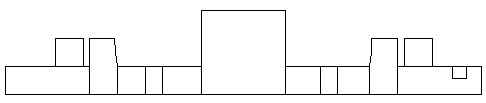

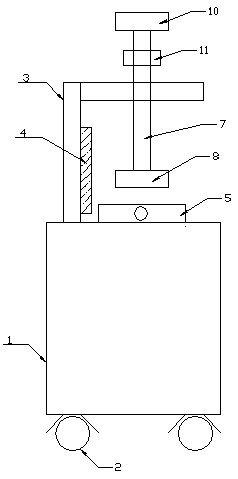

[0024] further as image 3 , Figure 4 and Figure 5 As shown, another aspect of the present invention provides a working method of a fast detection device for a dust shield. During detection, firstly, the dust shield to be measured is installed on the dust shield fixing seat 5, and then passes through the dust shield fixing seat 5. The thread-type adjusting bolt 6 set on the top will fix the dust shield to be measured, and then press down the mold base 8 with the same structure as the dust shield to be measured through the control handle 10, and finally observe the connection between the linkage rod 7 and the mold base 8. Scale scale 9, whether the error is within the allowable range, if so continue to the next process, if not screen out.

[0025] The rapid detection device of this structure has a reasonable design, convenient loading and unloading (the dust shield to be measured), and can replace the mold base 8 at the same time, which can meet the measurement requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com