Test method for motor under high-temperature and low-pressure environment

A low-voltage environment and test method technology, applied in the direction of motor generator testing, etc., can solve the problem of not meeting the motor test and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

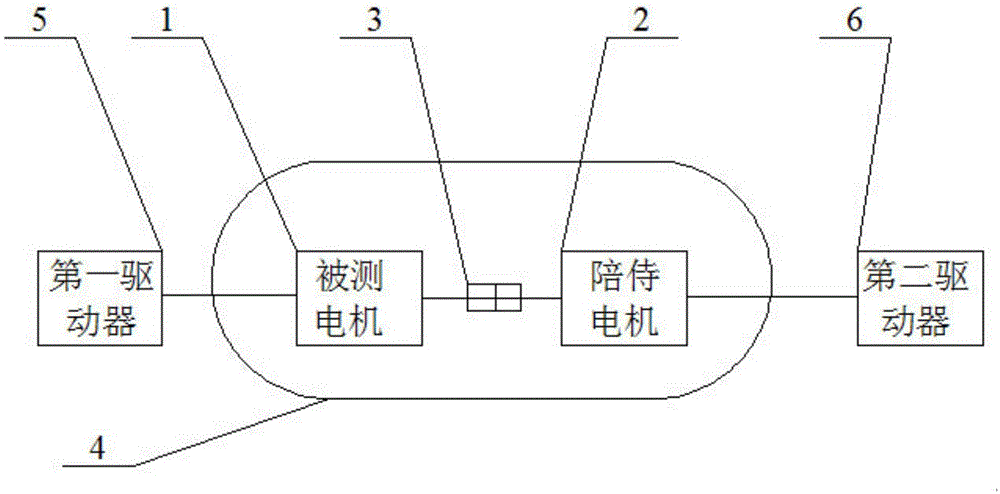

[0027] Specific implementation mode one: combine figure 1 Shown, illustrate the technical scheme of this embodiment, its method step is:

[0028] Step 1: Select a motor with the same specifications as the tested motor 1, or a motor with the same synchronous speed as the tested motor 1 but with a power greater than the tested motor 1 as the accompanying motor 2; the output shaft of the tested motor 1 Connect the output shaft of the accompanying motor 2 through the coupling 3, and then put it into the high-low temperature, low-pressure test box 4 and fix it. Set the test temperature in the high-low temperature, low-pressure test box 4 between 100°C and 200°C. The air pressure value is set at less than 0.01Mpa, making it close to the pressure value of the vacuum environment in outer space;

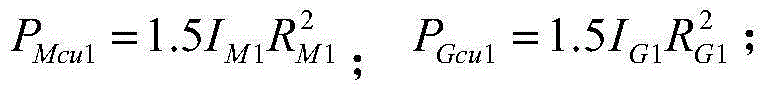

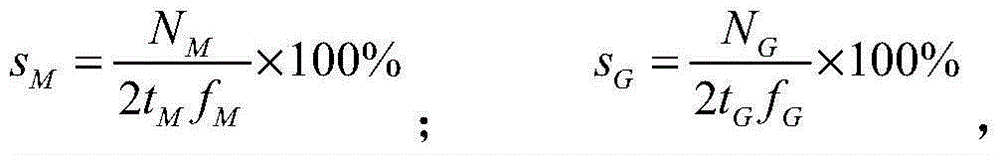

[0029] Step 2: make the tested motor 1 work in the motor state, and the accompanying motor 2 work in the generator state; the first driver 5 drives the tested motor 1 to run and work, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com