Prepressing type feeder

A feeder and pre-pressing technology, which is applied in the field of wood product manufacturing, can solve the problems of low efficiency and injury to workers when squeezing branches, and achieve the effect of stable and uniform squeezing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

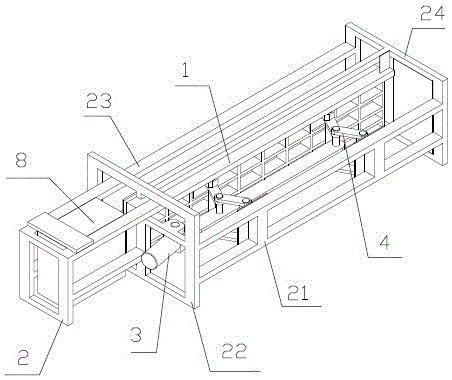

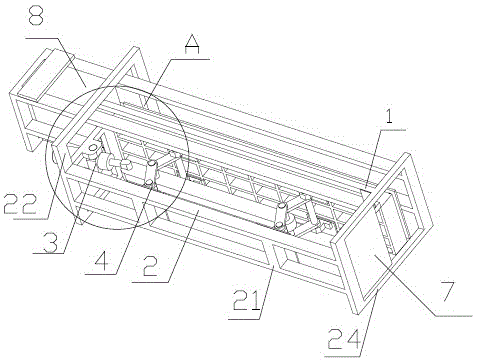

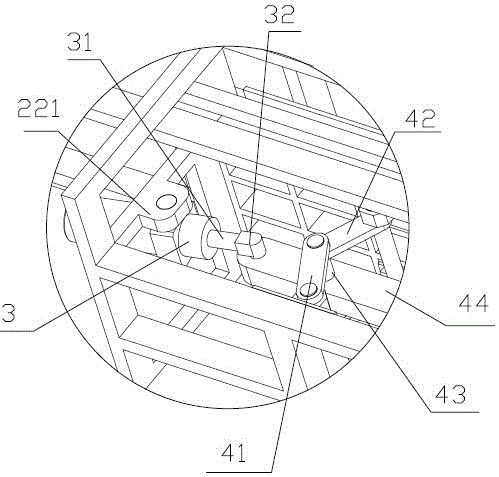

[0036] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 Shown: a pre-pressing feeder, including a frame 2, the frame 2 includes two side frames 21 on both sides and a front stop frame 24 at the front end, and one side frame 21 is connected for extruding The side pressing plate 1 of raw material, another side frame 21 is provided with panel 23 to be pressed, and front stop frame 24 is provided with empty groove and can slide on front stop frame 24 and can adjust the front baffle plate 7 of blocking empty groove, this This pre-compression feeder also includes a push-out device 8 that slides along the extension direction of the side frame 21, close to and away from the front stop frame 24, and connects the side frame 21 with the side pressing plate 1 and drives the side pressing plate 1 to move closer to and away from the panel to be pressed. 23, the sliding direction of the side plate 1 is in common with the sliding direction of the front baffle plate 7, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com