Hook mechanism for automatic vehicle connecting device

An automatic connection and vehicle technology, applied in vehicle components, traction connectors, transportation and packaging, etc., can solve problems such as heavy workload, low efficiency, and easy disengagement of hooks, to simplify operations, reduce labor intensity, and reduce safety. Effects on the probability of occurrence of accidents and body-in-white damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

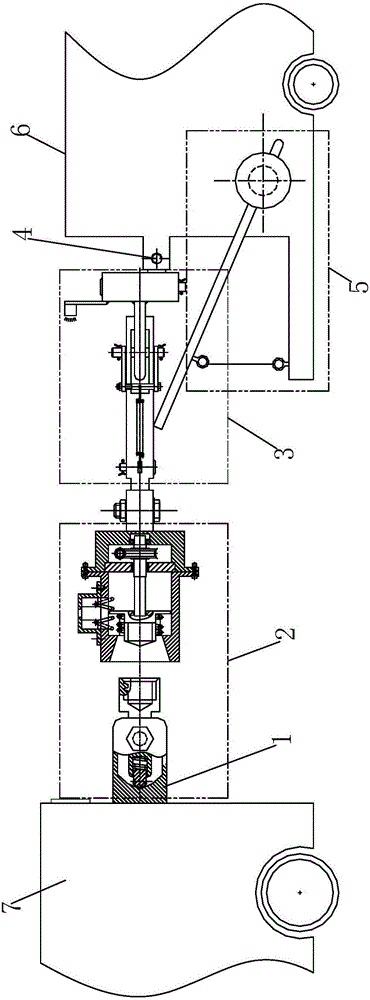

[0040] When the present invention is actually used, it needs to form a vehicle automatic coupling device together with the steering mechanism 3 and the centering mechanism 4, specifically, as figure 1The shown vehicle automatic coupling device includes a connecting seat 1 arranged on a station tool car 7, a hook mechanism 2, a steering mechanism 3 and a centering mechanism 4 arranged on a tractor 6; wherein,

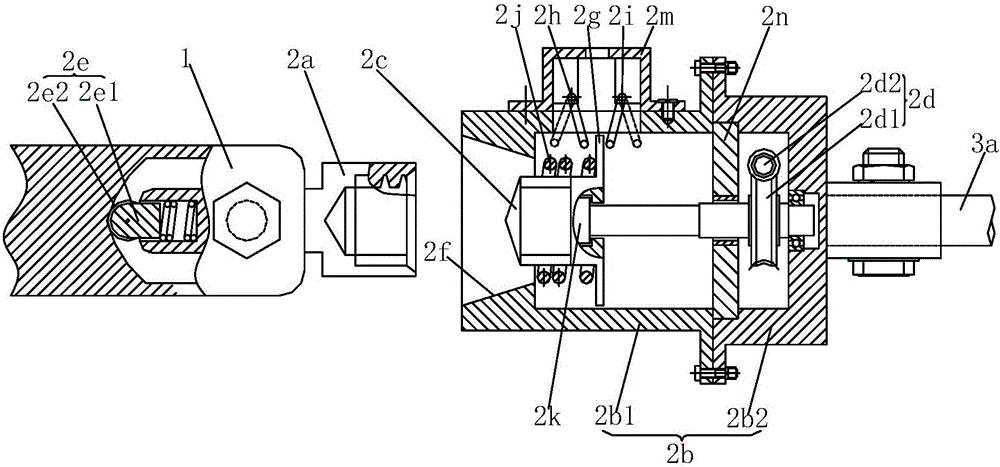

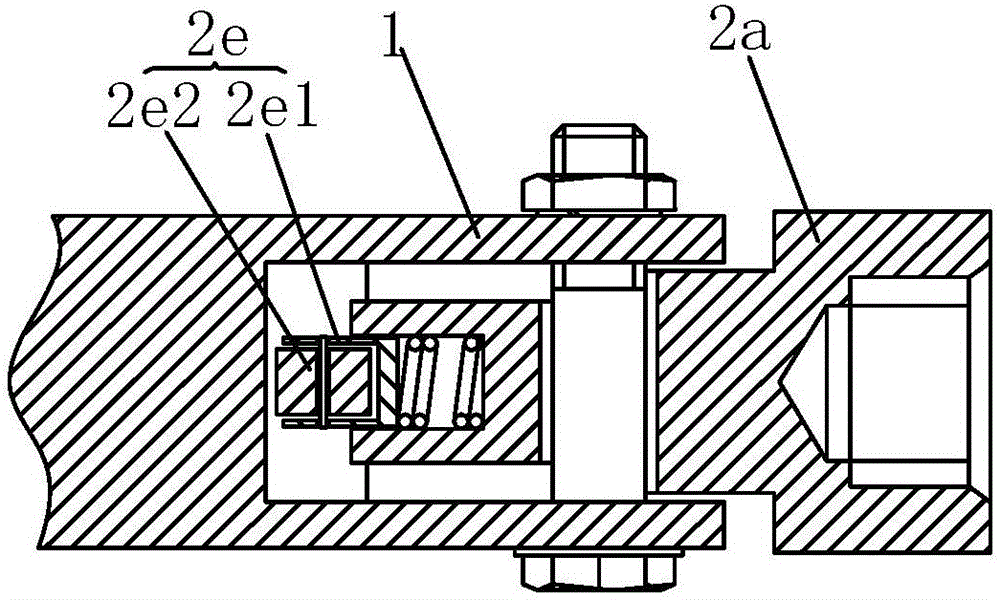

[0041] The hook mechanism 2 includes a coupling nut 2a and a housing 2b, the coupling end of the coupling nut 2a is inserted and horizontally hinged in the connecting seat 1, the connecting seat 1 is provided with an involute groove 1a, the The connecting end of the coupling nut 2a is equipped with a telescopic vibration roller 2e, and the vibration roller 2e is rollingly supported in the involute groove 1a, and the butt end of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com