Waterway change-over valve and water purifier with waterway change-over valve

A technology for switching valves and water purifiers, applied to multi-way valves, valve devices, engine components, etc., which can solve problems such as difficult to determine, inconvenient to use, and increase hidden dangers of product leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

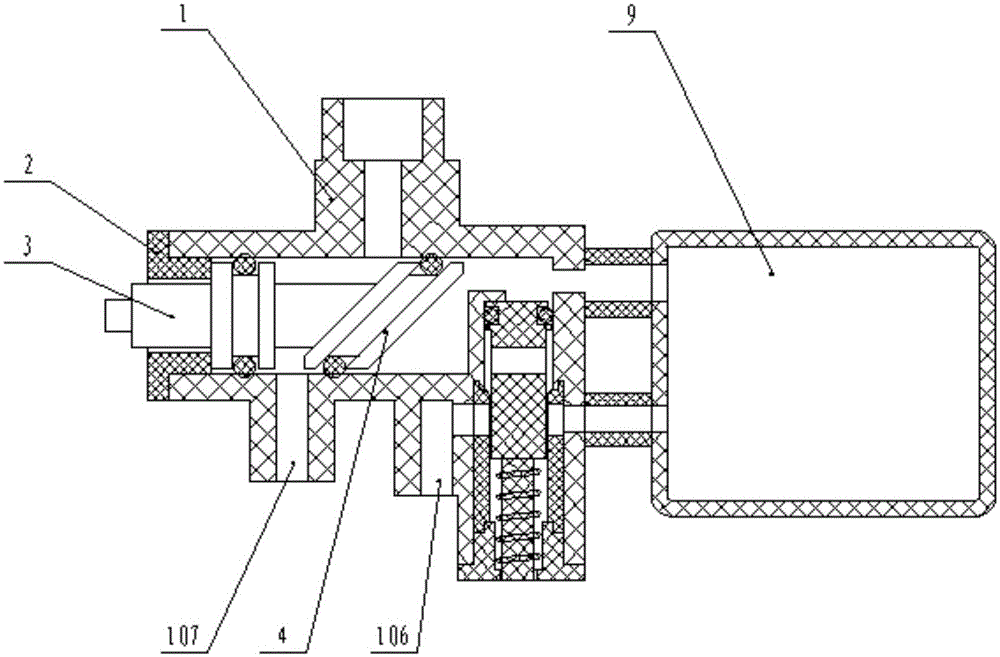

[0025] A water purifier with a waterway switching valve, including a water purifier and a waterway switching valve.

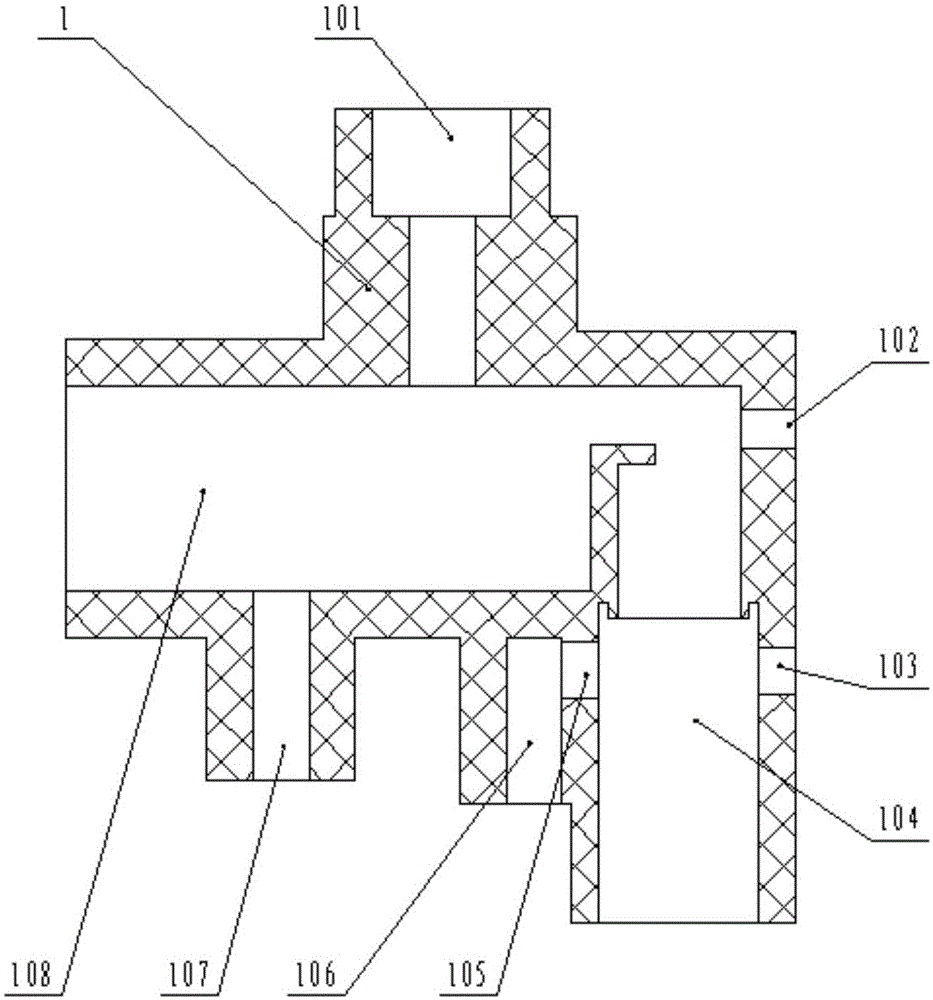

[0026] Wherein, the waterway conversion valve includes a valve body 1, such as figure 1 As shown, the valve body 1 is provided with a raw water inlet 101, an inner cavity 108 communicated with the raw water inlet 101, a first raw water outlet 102 and a second raw water outlet 107 communicated with the inner cavity 108, and the valve body 1 is also provided with There is an overflow valve cavity 104 communicated with the inner cavity 108, a filtered water inlet 103 and a filtered water outlet 106 communicated with the overflow valve cavity 104, and the filtered water inlet 103 and the filtered water outlet 106 are connected with the water purifier 9 at the same time. The water inlet and the water outlet are connected, and the raw water inlet 101 is connected with the tap.

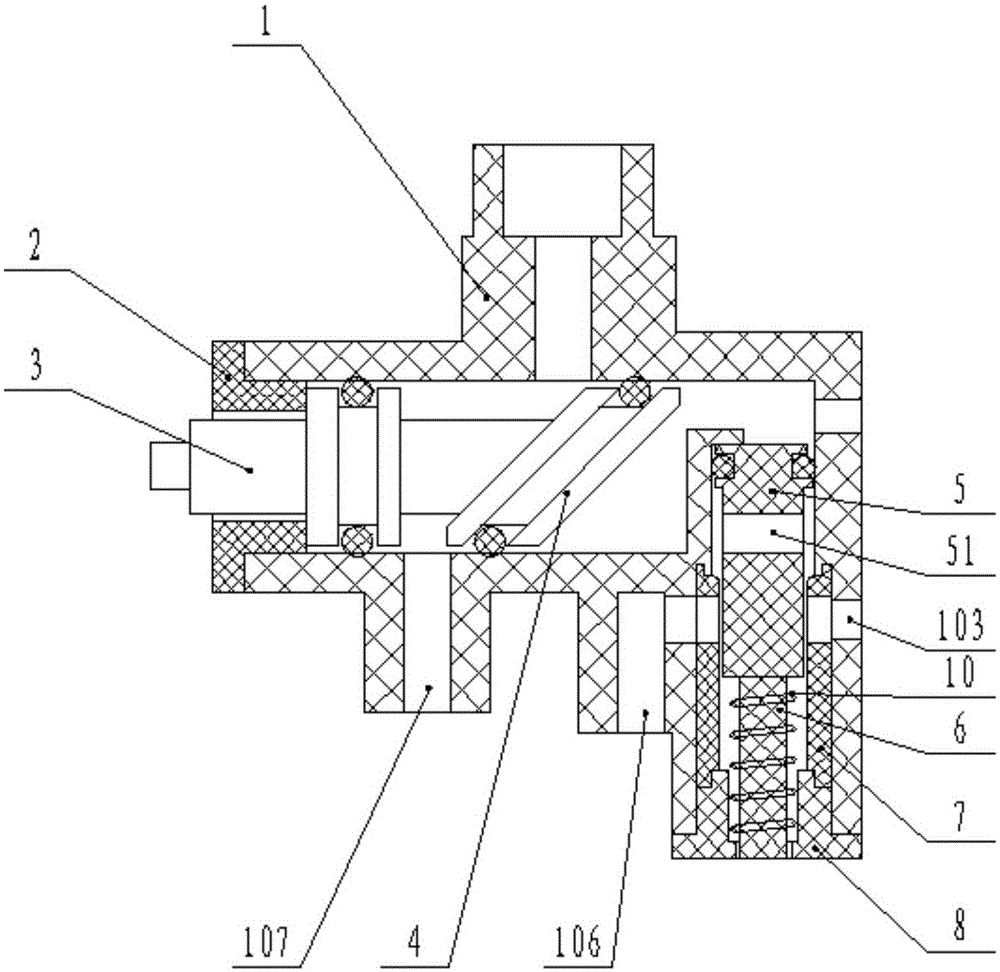

[0027] Such as figure 2 As shown, the reversing valve stem 3 extends into the inner ca...

Embodiment 2

[0031] Such as Figure 5 As mentioned above, the reversing spool 4 is relative to the attached Figure 4 Rotate 180°, at this time, the projection of the raw water inlet 101 along its axial direction is located in the lower bottom surface 402 of the valve core 4 of the reversing valve core 4, and the tap water flows into the inner cavity 108 from the raw water inlet 101, and then passes through the second inner cavity 108. The raw water outlet 107 flows out of the waterway switching valve. At this time, the upper end surface of the overflow valve core 5 is not subjected to water pressure, the overflow valve core 5 is located at the upper end of the overflow valve cavity 104 , and no water flows out from the filtered water outlet 106 .

Embodiment 3

[0033]Close the water tap connected to the waterway conversion valve, now no tap water flows into the raw water inlet 101, there is no water in the cavity 108, the overflow valve core 5 is located at the upper end of the overflow valve cavity 104, and no water flows out from the filtered water outlet 106.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com