Lamp anti-disengagement light dimming mechanism capable of achieving inner and outer combined assembling

A combination of inside and outside, lighting technology, applied to the components of lighting devices, electric light sources, motor vehicles, etc., can solve the problems of increased space requirements for lighting fixtures, complicated manufacturing processes for plastic screws and bevel gears, and inconvenient lighting layouts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

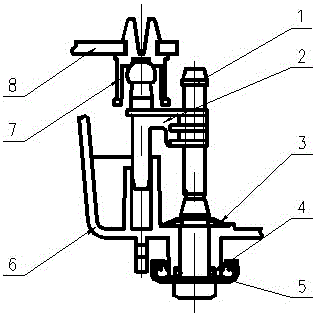

[0020] Depend on figure 1 It is well known that an anti-off dimming mechanism for lamps assembled internally and externally is composed of a gear screw 1, a ball head fixing buckle 2, a limit card 3, a sealing ring 4, an increasing slip gasket 5, a lamp housing 6, and a ball seat fixing buckle 7 , the adjusted workpiece 8, the gear screw 1 is fixed on the lamp housing 6 through the limit card 3, the slip pad 5 is arranged between the gear screw 1 and the lamp housing 6, the ball head fixing buckle 2 and the lamp housing 6 cooperate to realize the up and down guidance during thread adjustment; the ball seat fixing buckle 7 is arranged on the ball head fixing buckle 2, and the one side clamping foot of the ball seat fixing buckle 7 is connected with the adjusted part 8.

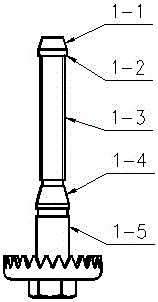

[0021] Depend on figure 2 It is a schematic diagram of the gear screw 1. The gear screw 1 is composed of chamfer I1-1, limit post 1-2, stud 1-3, chamfer II1-4, cylinder 1-5, and the outer diameter of limit p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com