A Calculation Method of Civil Aircraft System Maintenance Time Interval

A technology of maintenance time and civil aircraft, which is applied in the aviation field and can solve the problems of high maintenance costs, loss of profits, and insufficient maintenance of airlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

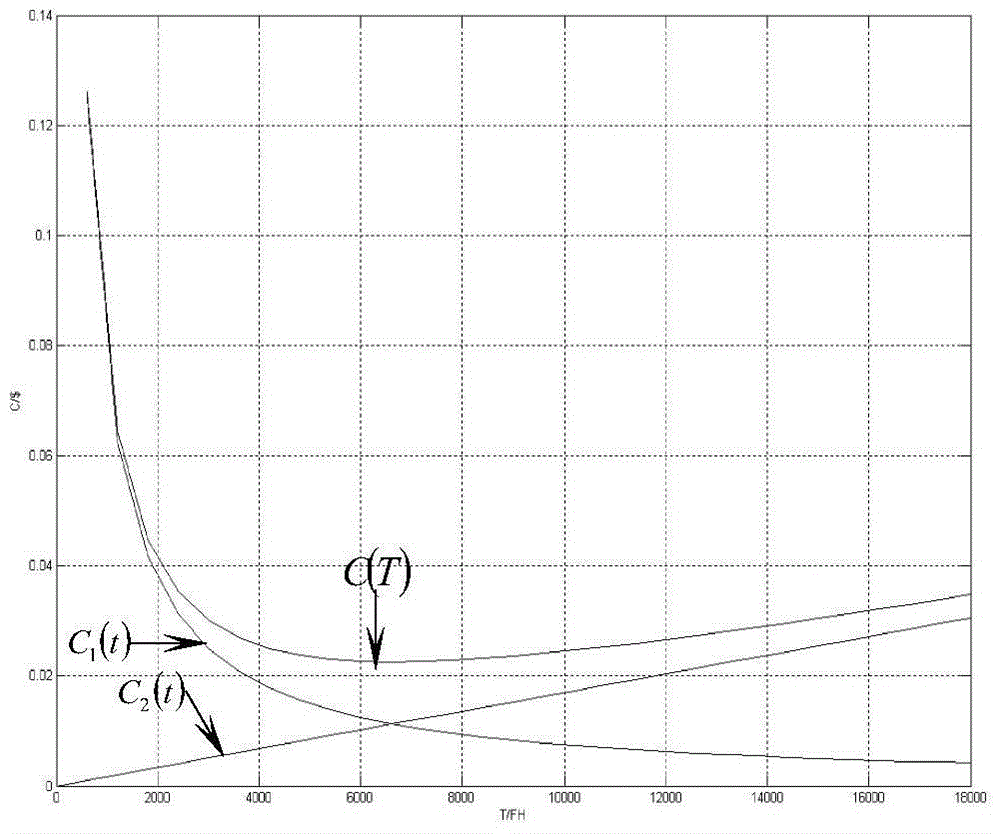

[0078] Example 1: In this example, the application test of the CRJ700 emergency light system of an in-service aircraft is carried out. The specific steps are as follows:

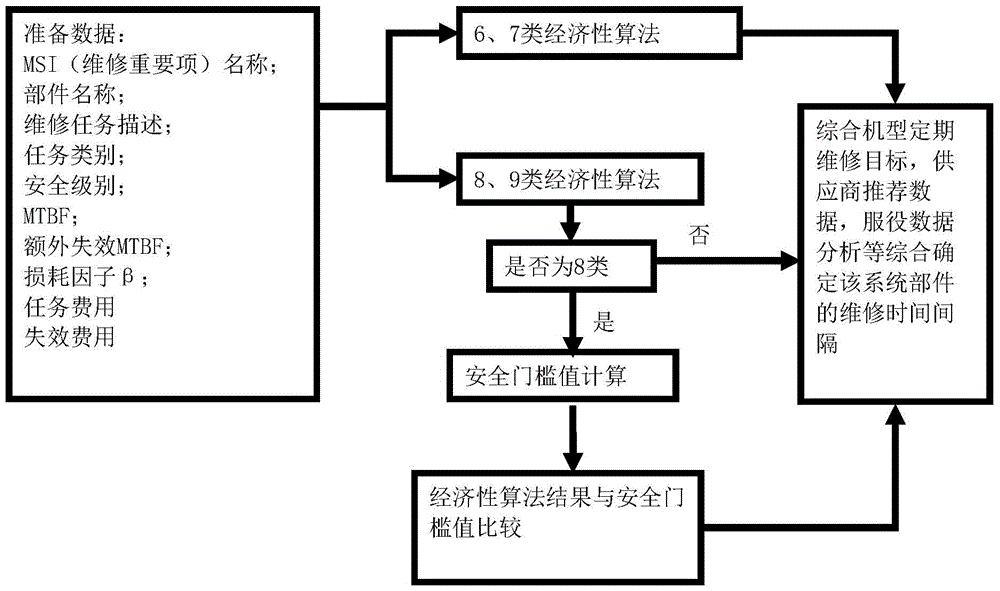

[0079] Step 1: Prepare Data

[0080] Including the name of important maintenance items, component names, maintenance task description, task category, safety level, mean time between failures, additional failure mean time between failures, loss factor, - task cost and failure cost, where the task category is the Common sense in the field, category 5 is explicit safety category, category 6 is explicit operation category, category 7 is explicit economic category, category 8 is implicit security category, and category 9 is implicit non-safety category. For details, please refer to MSG -3, 2009.1. The main failure mean time between failures, the additional failure mean time between failures, and the loss factor are all determined according to different component types, and they are all fixed values.

[0081] MS...

Embodiment 2

[0143] Embodiment 2: In this example, the present invention is applied to the CSeries emergency light system of Bombardier's newly developed aircraft, and data such as CSeries direct maintenance cost analysis, maintainability analysis, and reliability analysis are used as input. Its calculation method is the same as that of Embodiment 1, the difference lies in that the specific parameter settings are different.

[0144] MSI (Maintenance Important Item): emergency light system;

[0145] Selected components: emergency lights and signs;

[0146] Task description: Operational inspection of emergency light system;

[0147] Task category: 8;

[0148] Security level: Injury;

[0149] MTBF: 103018FH,

[0150] Additional invalidation: 1.0E+5;

[0151] Loss factor β: 1.0;

[0152] Task cost:

[0153] ●GSE:0;

[0154] ●Manpower working hours: 0.15 hours

[0155] ●Materials / consumables: 0

[0156] ●Number of executives: 1

[0157] invalidation fee

[0158] ...

Embodiment 3

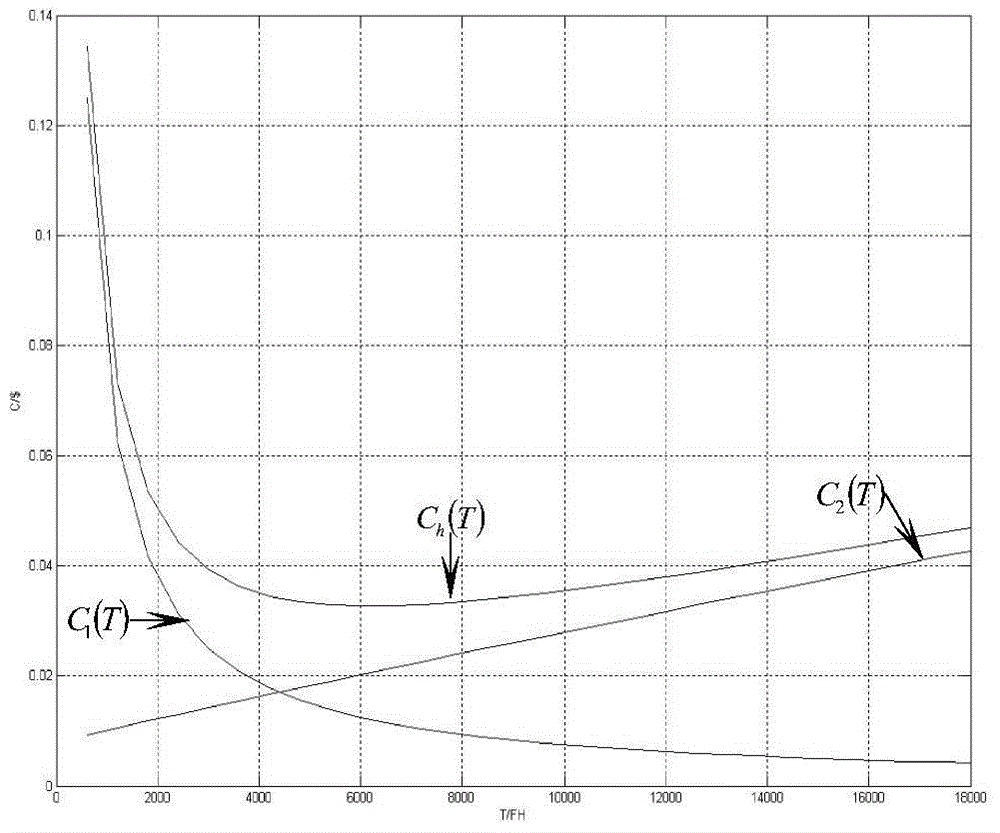

[0175] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the task category is the sixth category of the dominant category

[0176] E.g:

[0177] MSI (maintenance important item): CRJ elevator;

[0178] Selected parts: Elevator control cables;

[0179] Task description: Functional inspection of elevator control cables;

[0180] Task category: 6;

[0181] Security level: other;

[0182] MTBF: 30000;

[0183] Additional failure: not applicable;

[0184] Loss factor β: 2.2;

[0185] Task cost:

[0186] ●GSE:0;

[0187] ●Manpower working hours: 4 hours

[0188] ●Materials / consumables: 0

[0189] ●Number of executives: 1

[0190] invalidation fee

[0191] ●Repair cost: 500$

[0192] ●Working hours: 3 hours

[0193] ●Flight delay: No;

[0194] ●Flight cancellation: a loss of 30,000$;

[0195] ●Turn to fly: No;

[0196] ●Time interval adjustment value: 5000

[0197] ●Materials / Consumables: 0;

[0198] ●Number of days of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com