Vacuum cleaner nozzle with sealing edge

A vacuum cleaner, edge technology, applied in the direction of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve problems such as annoying vacuum cleaner nozzles, tilting vacuum cleaner nozzles, uncomfortable jumping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

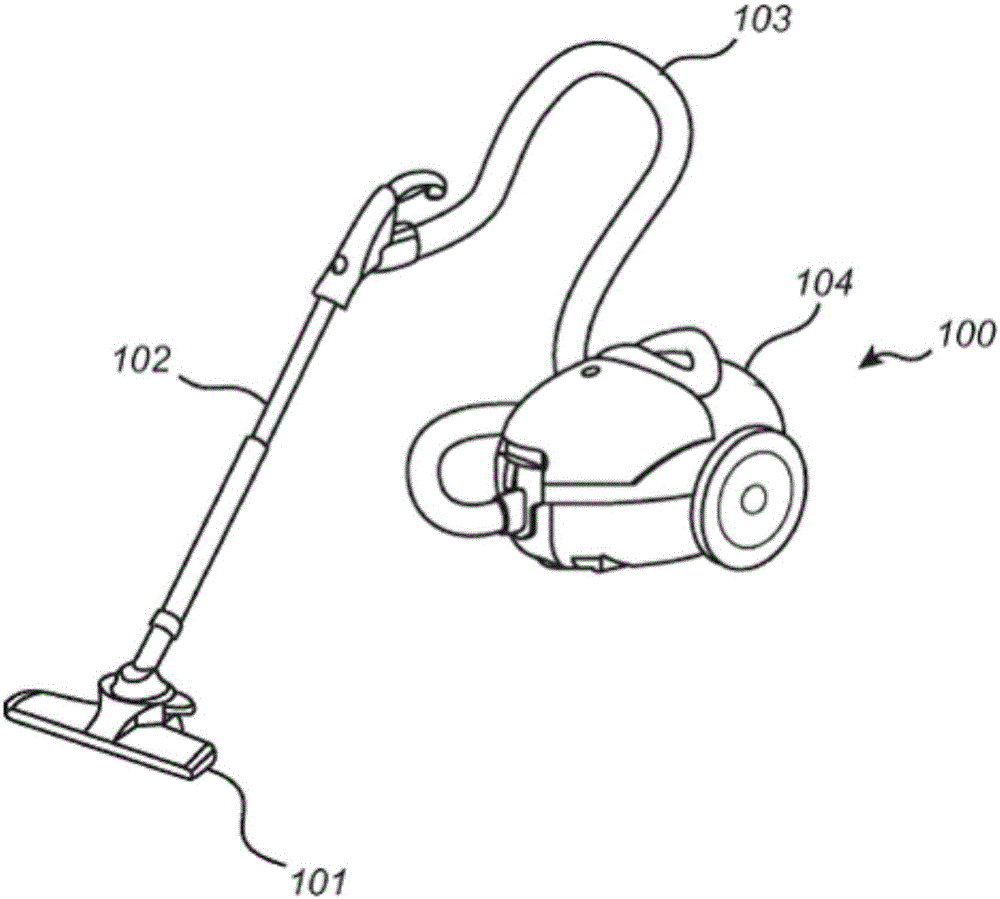

[0031] figure 1 A vacuum cleaner 100 is shown comprising a nozzle 101 according to an embodiment. The suction nozzle 101 may be connected to the main body 104 of the vacuum cleaner 100 via a tube 102 and a hose 103 .

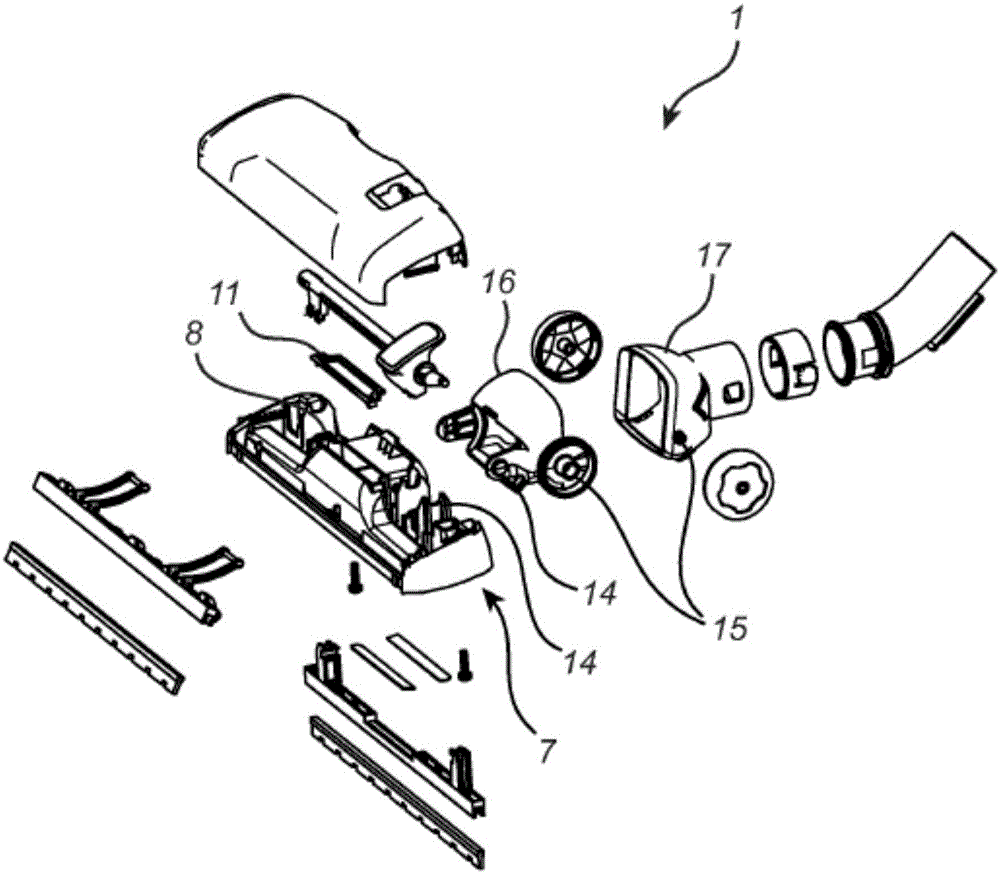

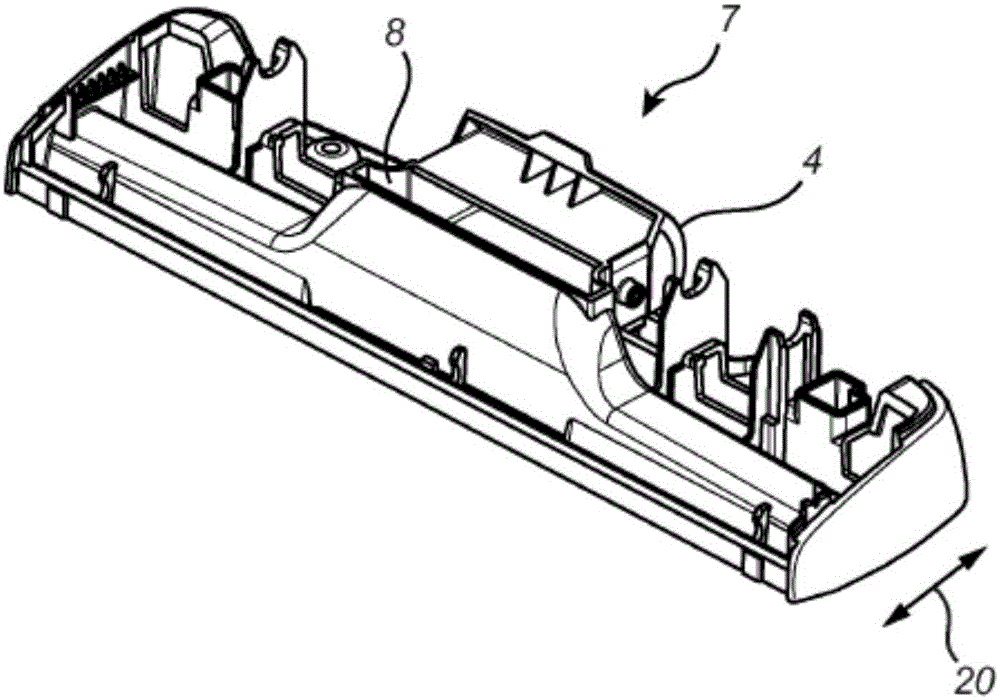

[0032] refer to figure 2 A vacuum cleaner nozzle according to an embodiment will be described. figure 2 is an exploded view of a suction nozzle 1 comprising several rigid parts 7, 16, 17 interconnected to each other by one or more joints 14, 15 (or hinged connections). The suction nozzle 1 comprises a suction disc 7 connected to an intermediate part 16 by means of a hinged connection 14 , whereby the suction disc 7 is arranged to pivot relative to the intermediate part 16 . The nozzle 1 also comprises an outlet part 17 adapted to be coupled (directly or indirectly) to a hose of the vacuum cleaner and connected to the intermediate part 16 via the hinged connection 15 . Thus, the three rigid parts 7, 16, 17 may be arranged to pivot at least slightly relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com