foam soap dispenser

A soap dispenser and foam-type technology, which is applied in the field of soap dispensers, can solve the problems of different sizes of foam bubbles, unstable foam volume, and low foam volume, and achieve controllable foam volume, rich and delicate foam, and high foam volume. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

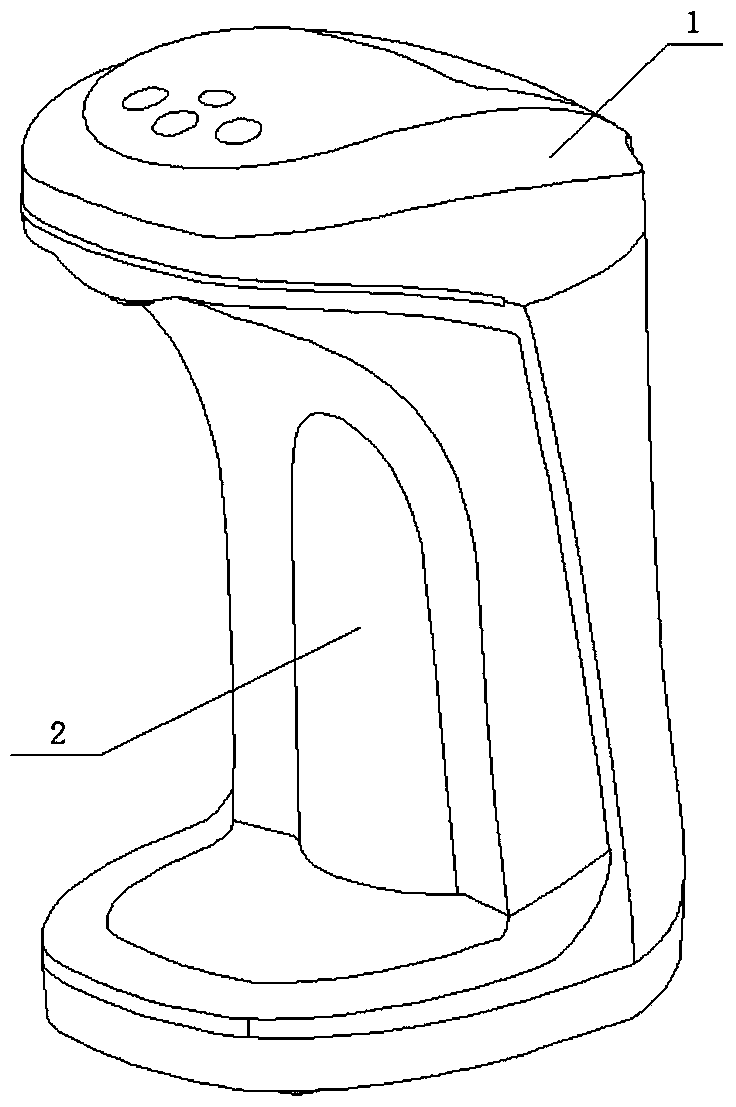

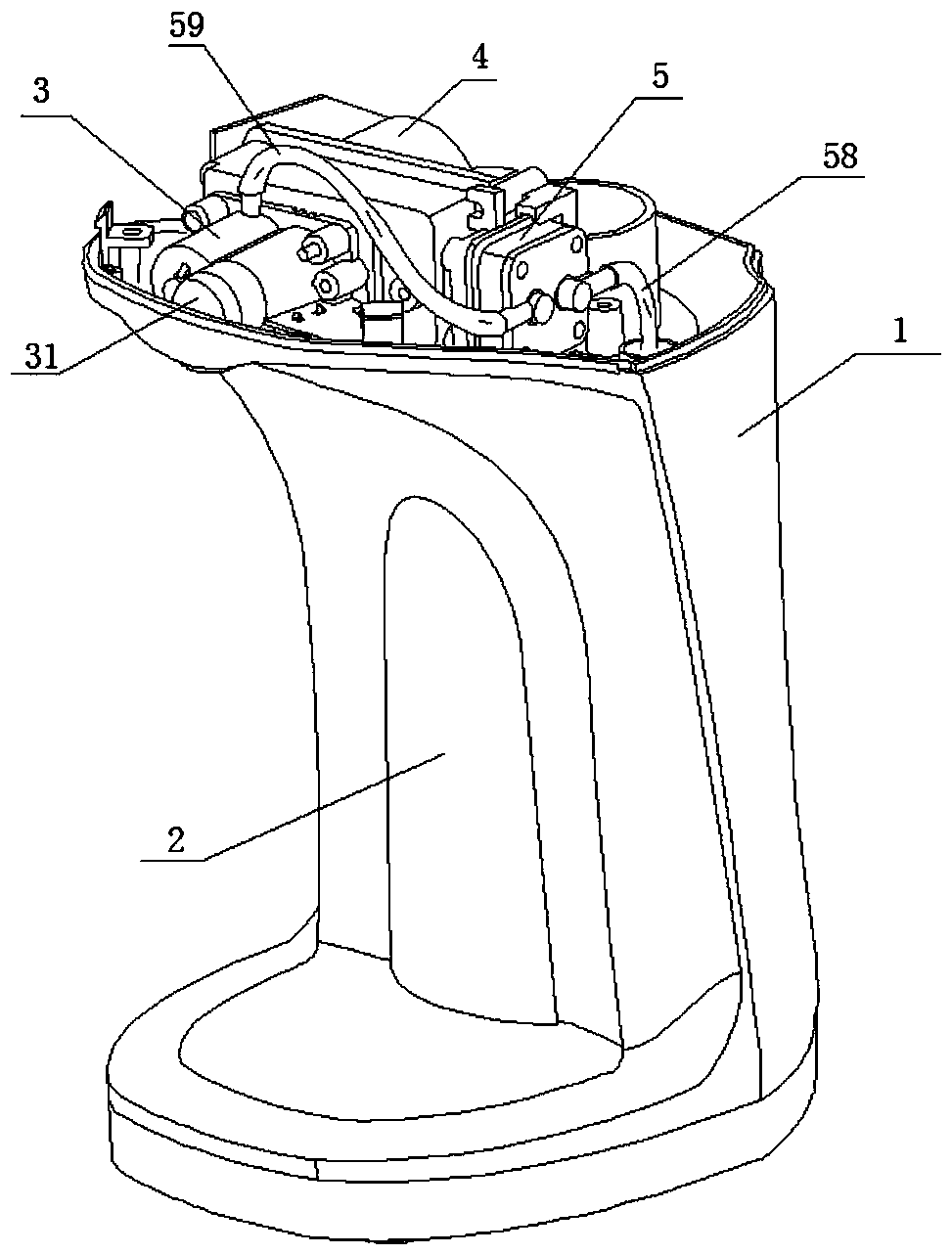

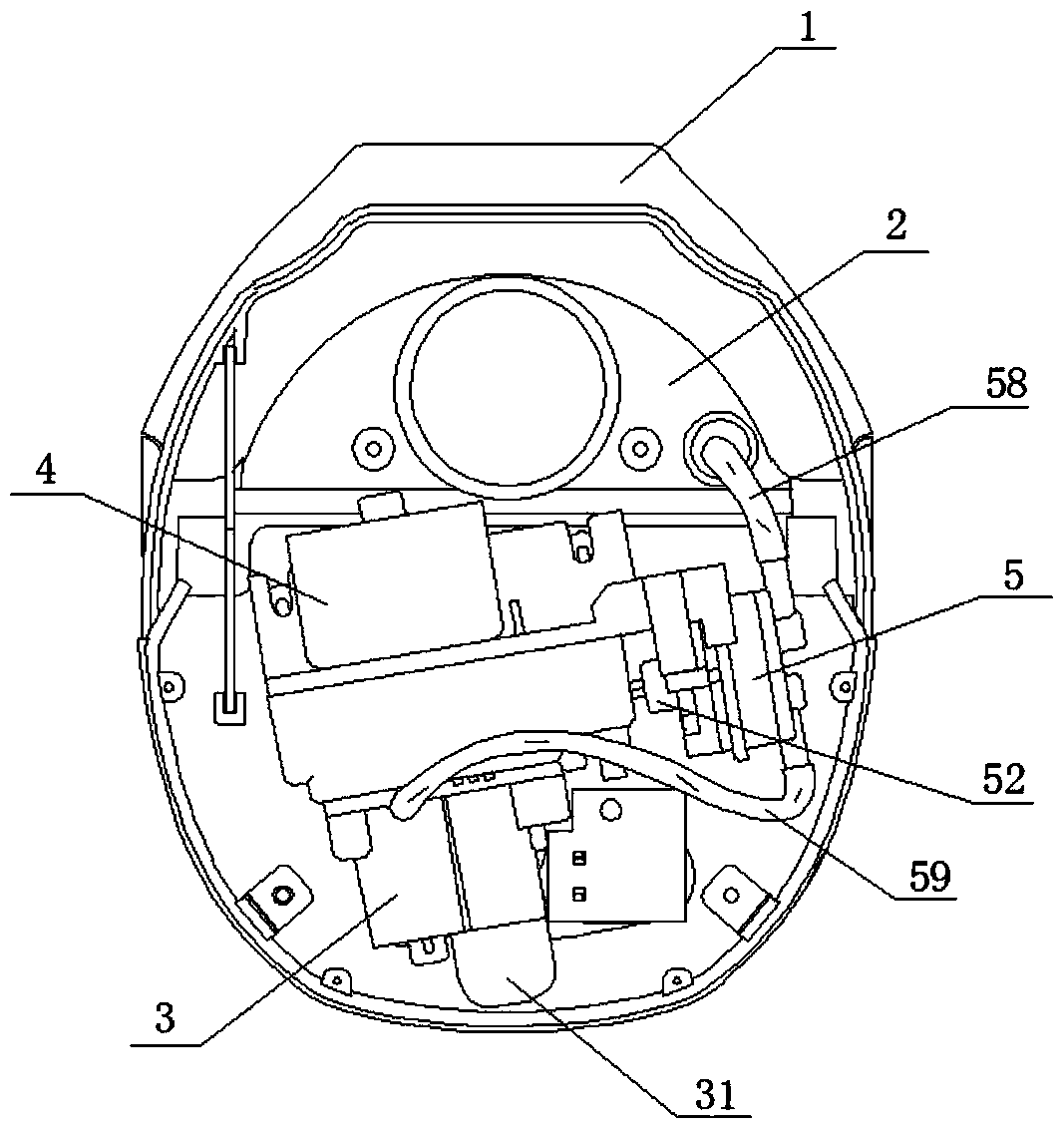

[0023] like Figure 1-Figure 11 As shown, the present invention discloses a foam type soap dispenser, which includes a housing 1 , and a liquid storage bottle 2 , an induction control device, a power device, an extracting device and a foam making device 3 arranged in the housing 1 .

[0024] The extraction device includes a pressure pump 5 with a liquid inlet A and a liquid outlet B. The foam making device 3 includes a one-way air inlet 35 and a foam chamber 34 with a nozzle 31. The liquid inlet of the pressure pump 5 A is communicated with the liquid output port of the liquid storage bottle 2, and the liquid outlet B of the pressure pump 5 is communicated with the foam-making cavity. A toothed screw shaft 32 and a smooth screw shaft 33 are arranged in the foam-making cavity 34. The toothed screw shaft 32 and the pressure pump 5 are respectively connected with a power device, and the power device provides power for the toothed screw shaft 32 and the pressure pump 5 . The powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com