Printing register lock-up device based on FPGA and register lock-up method thereof

A printing color and base material technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as system stop working, positioning registration splicing device unfolding preset threshold, printing cursor running out of the threshold, etc., to overcome waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

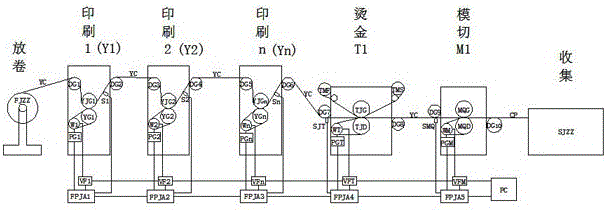

[0029] This embodiment provides a FPGA-based printing register positioning device, such as figure 1 As shown, it includes FPGA unit, printing color group motor driver, printing color group motor linkage digital frequency encoder, and printing color group graphic collector.

[0030] The above-mentioned FPGA unit is respectively connected with the printing color group motor driver and the printing color group motor linkage digital frequency encoder. The printing color group motor driver drives the printing plate roller to print the printing substrate by controlling the printing color group motor. The printing color group The graphics collector is arranged downstream of the printing pressure rubber roller and the printing plate roller, and is connected with the FPGA unit signal.

[0031] The above-mentioned printing color group graphic collector can be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com