throw device

A technology of center pipe and casing, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve problems such as inability to carry out cementing operations, and achieve the effects of avoiding oil wells from becoming obsolete, facilitating popularization and application, and eliminating obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

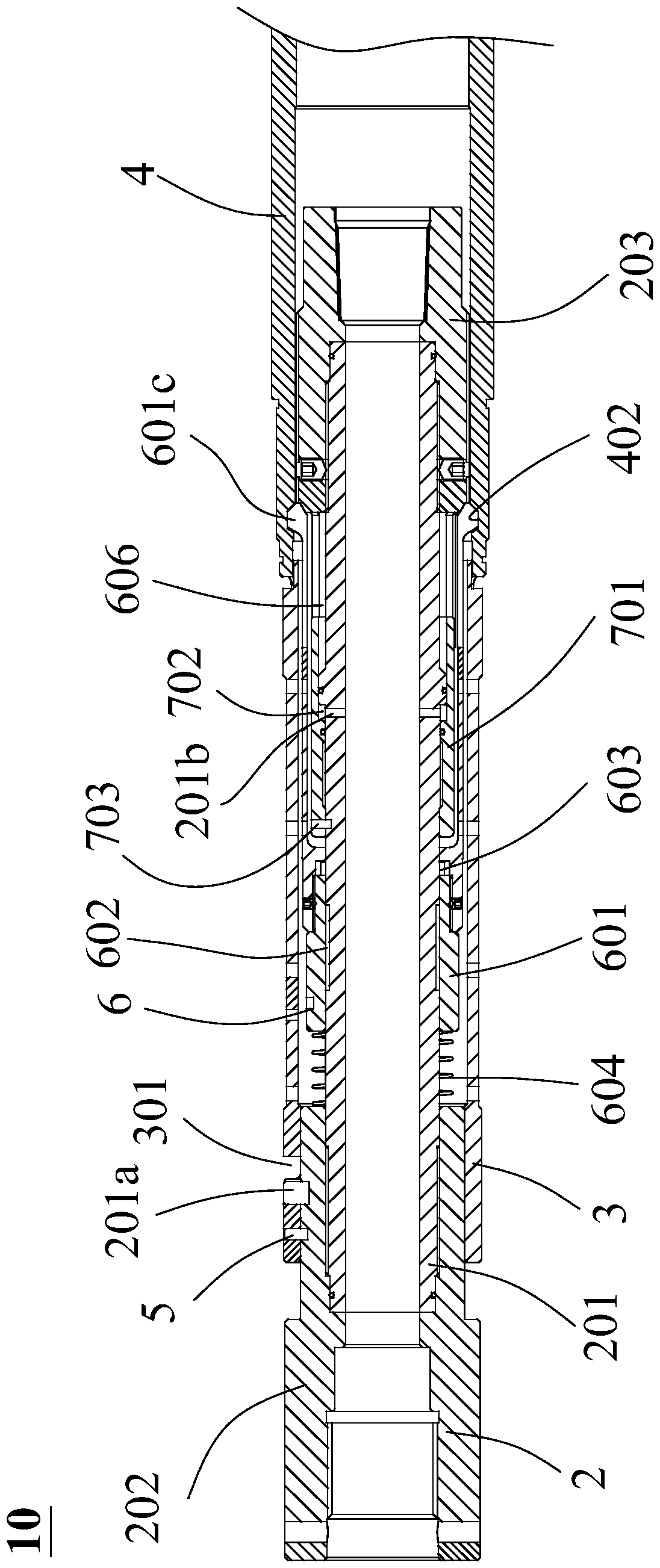

[0024] The present invention will be further described below with reference to the accompanying drawings.

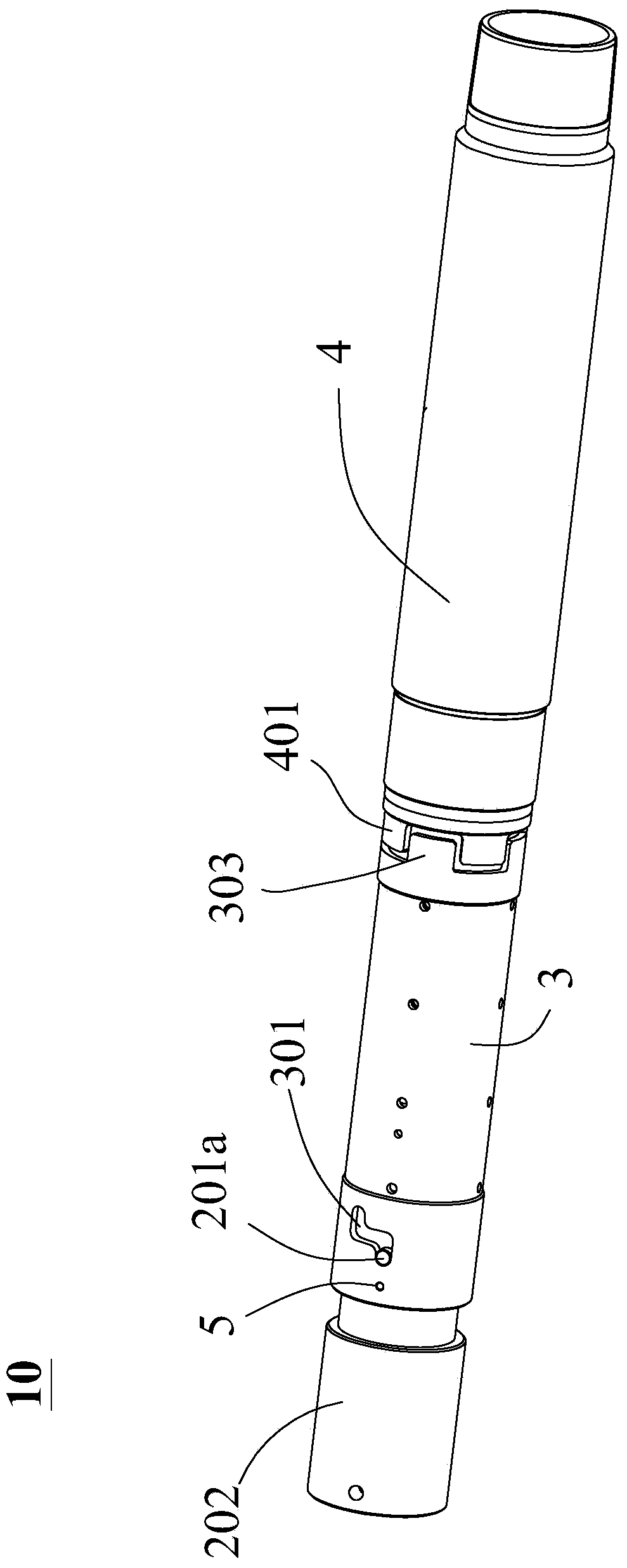

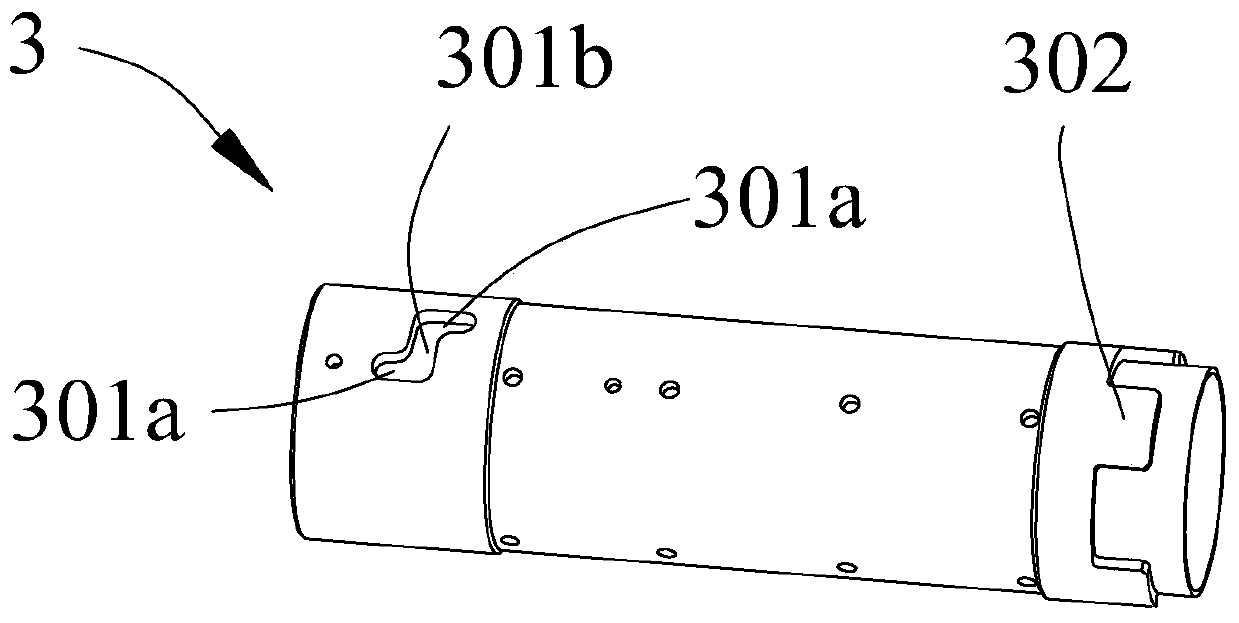

[0025] The main purpose of the throwing device according to the present invention is to throw the tailpipe hanger into the set position. like figure 1 and 2 As shown, the hand throwing device 10 according to the present invention includes a core tube assembly 2 . The core tube assembly 2 includes a central tube 201 , and tubular joints 202 and support members 203 respectively disposed at both ends of the central tube 201 . Preferably, the pipe joint 202 and the support member 203 are respectively sleeved outside the upstream end and the downstream end of the central pipe 201 through a threaded structure. The tubular joint 202 includes a transmission member 201a provided on the outer wall of its body. The transmission member 201a is preferably a pin, for example, fixed in the body of the pipe joint 202 through a threaded structure.

[0026] According to the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com