A micro-electromechanical fuze safety device

A micro-electromechanical and fuze technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of difficult to control the cooling process, limited use range, high size requirements, etc., achieve small structure size, meet space and time requirements, and respond block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

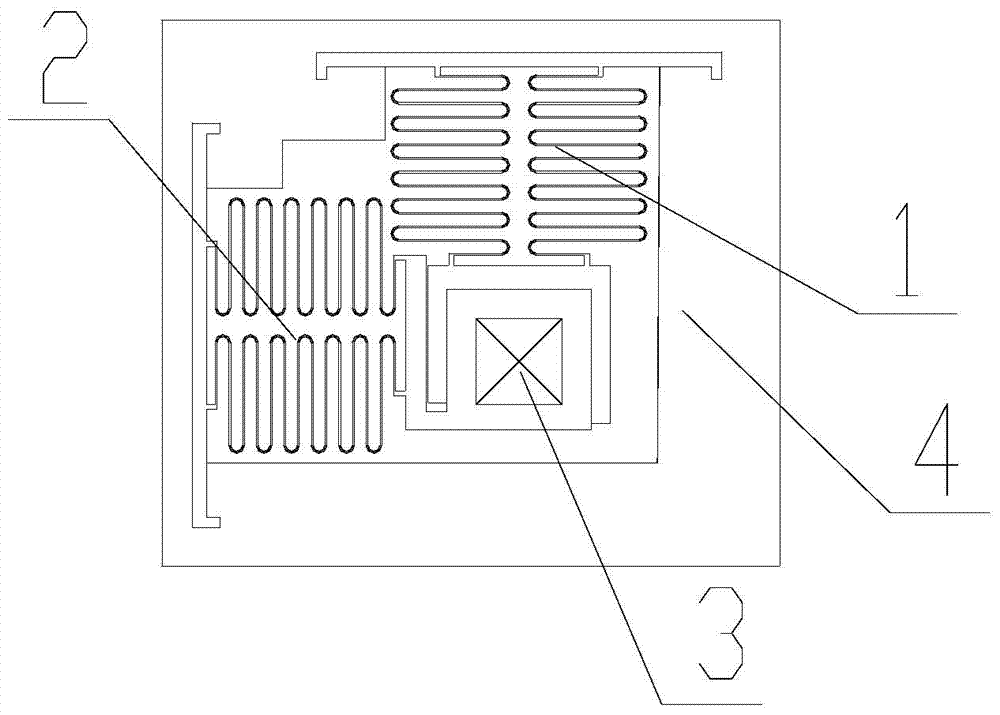

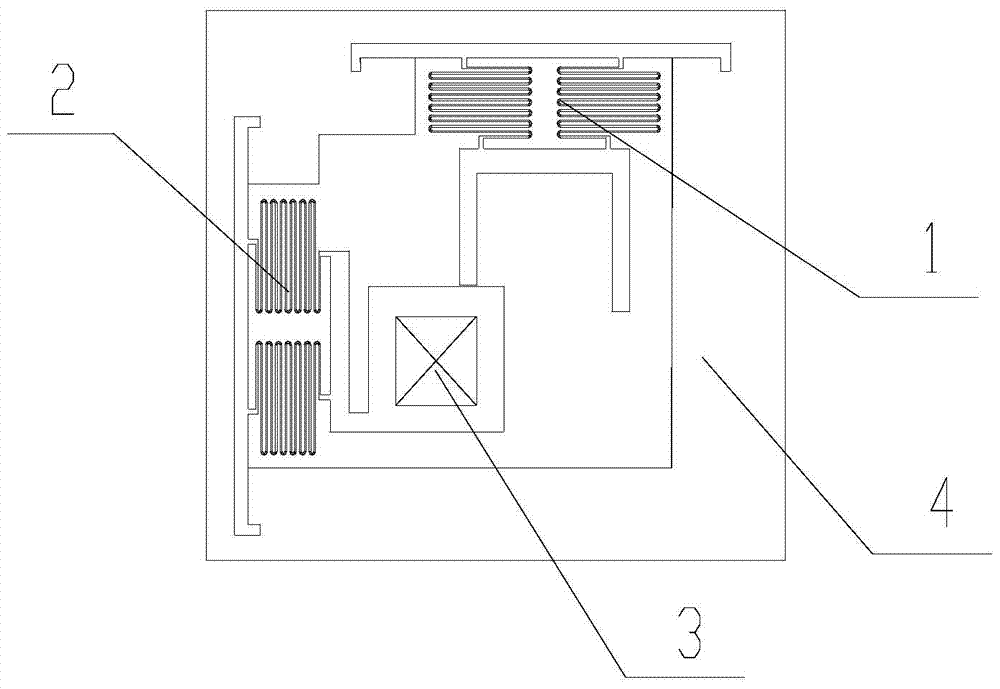

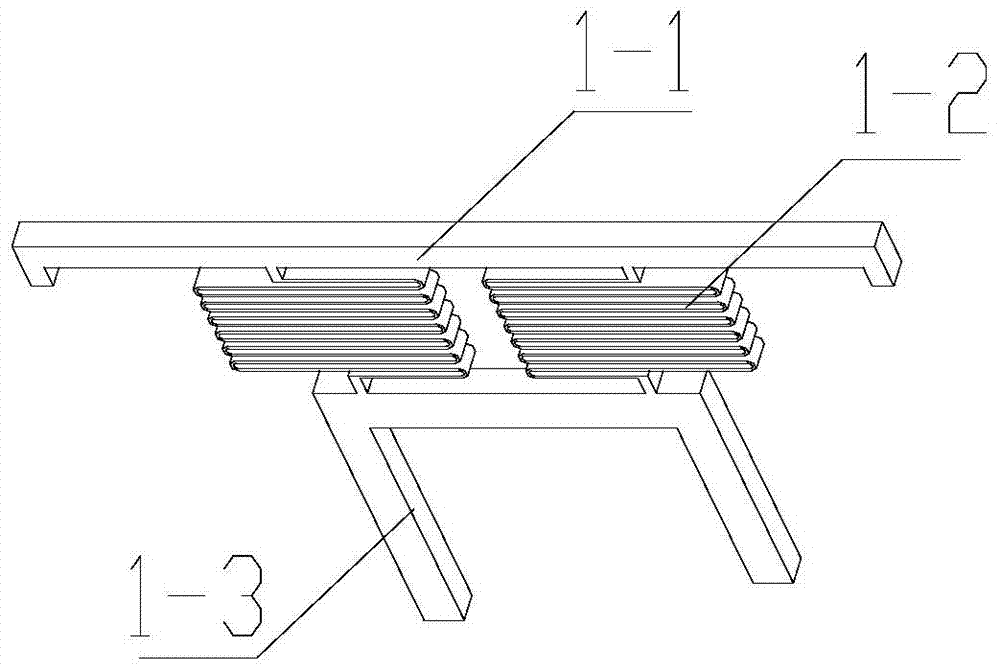

[0036] The longitudinal spring slider driver 1 , the transverse spring slider driver 2 and the frame 4 are all formed by integral etching of a 0.4 mm thick TiNi-based shape memory alloy film. The longitudinal spring 1-2 and the transverse spring 2-2 are two-way TiNi shape memory alloy material shortened at high temperature. The bracket is made of machinable ceramic material for the gyroscope.

[0037]Cover plates are installed on the upper and lower end faces of the present embodiment to form a closed fuze safety device. The size of the actual miniature fuze safety device (including the installation cover) is 20mm (length) × 20mm (width) × 1mm (height). Under the condition of 28V power supply, the time for the safety device to be released is about 2s, and the time for the safety to be restored is in place. About 2.5s.

[0038] However, in the patent "A Fuze Isolation Mechanism (Application No.: 201510078579.8)" previously declared by the applicant, under the condition of 28V...

specific Embodiment 2

[0039] In this embodiment, except that the longitudinal spring slider driver 1 , the transverse spring slider driver 2 and the frame 4 are integrally etched with a 1 mm thick TiNi-based shape memory alloy film. Other compositions and connections are the same as in Example 1.

[0040] Cover plates are installed on the upper and lower end faces of the present embodiment to form a closed fuze safety device. The size of the actually produced miniature fuze security device (including the installation cover) is 20mm (length) × 20mm (width) × 1.6mm (height). Under the condition of 28V power supply, the security device releases the insurance time for about 3.4s, and the insurance is restored in place. The time is about 5s.

specific Embodiment 3

[0041] In this embodiment, except that the longitudinal spring slider driver 1 , the transverse spring slider driver 2 and the frame 4 are integrally etched from a 0.5 mm thick TiNi-based shape memory alloy film. Other compositions and connections are the same as in Example 1.

[0042] Cover plates are installed on the upper and lower end faces of the present embodiment to form a closed fuze safety device. The size of the actually produced miniature fuze safety device (including the installation cover) is 20mm (length) × 20mm (width) × 1mm (height). Under the condition of 28V power supply, the time for the safety device to release the insurance is about 2.3s, and the insurance is restored to its place. The time is about 3s.

[0043] Since the shape memory alloy spring is etched as a whole, microcracks often appear in the spring with a thickness of 0.4mm, and the processing technology is relatively poor, while the number of microcracks in the spring with a thickness of 0.5mm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com