A semi-reversed construction technique for enclosure walls under construction conditions in winter

A technology of construction technology and reverse method, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult construction, difficult operation of construction technology, and inability to complete, and achieves the effect of high construction efficiency and short total construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0025] A semi-reverse method construction technology of the fence under winter construction conditions, which adopts the semi-reverse construction method from bottom to top and then from top to bottom to form fence columns. The specific process steps are:

[0026] ⑴For industrial processing of concrete columns, a qualified processing unit is pre-entrusted to process the concrete columns of the upper wall, and the columns need to be left with hanging points;

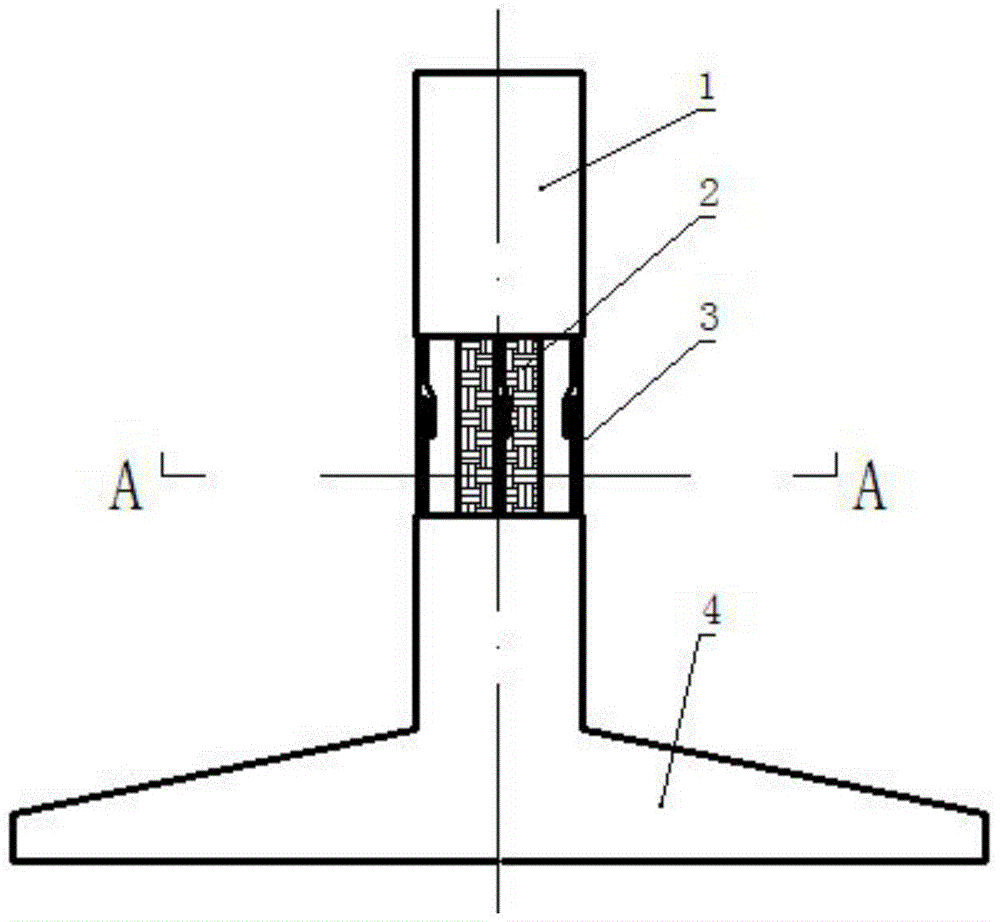

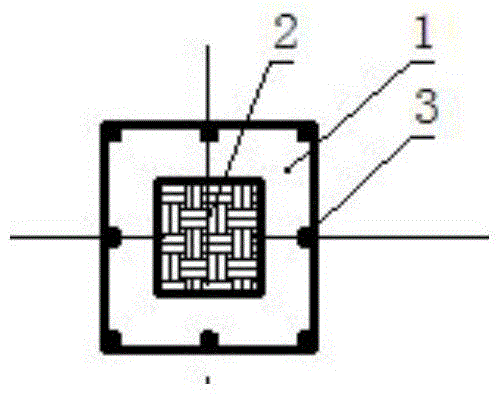

[0027] For the installation structure of the concrete column, please refer to the accompanying drawings in the manual, including the concrete foundation cap 4, the column body 1, the reserved support 2, and the column steel bar 3. The middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com