A kind of anti-creep expansion instrument

A technology of dilatometer and creep, applied in the field of anti-creep dilatometer, can solve problems such as creep deformation in the measurement direction, achieve the effect of ensuring measurement accuracy and overcoming high temperature creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

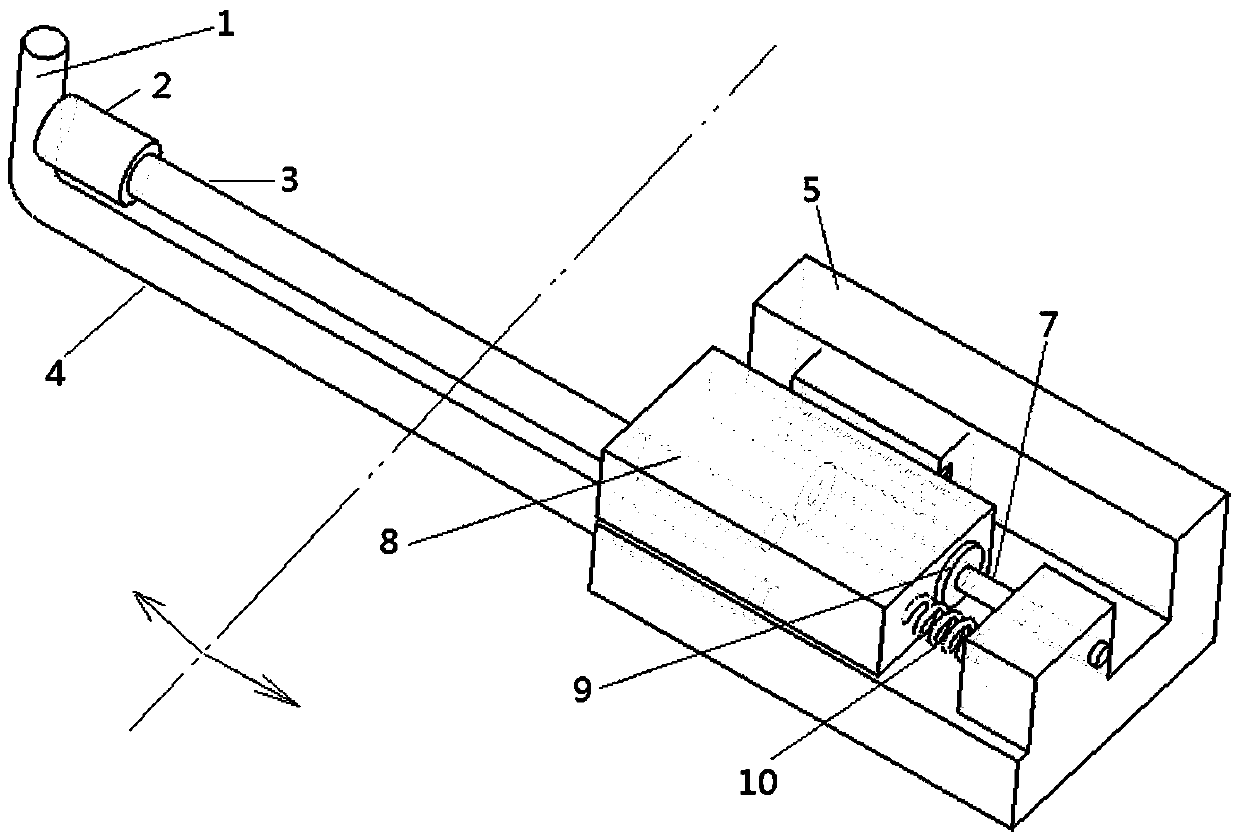

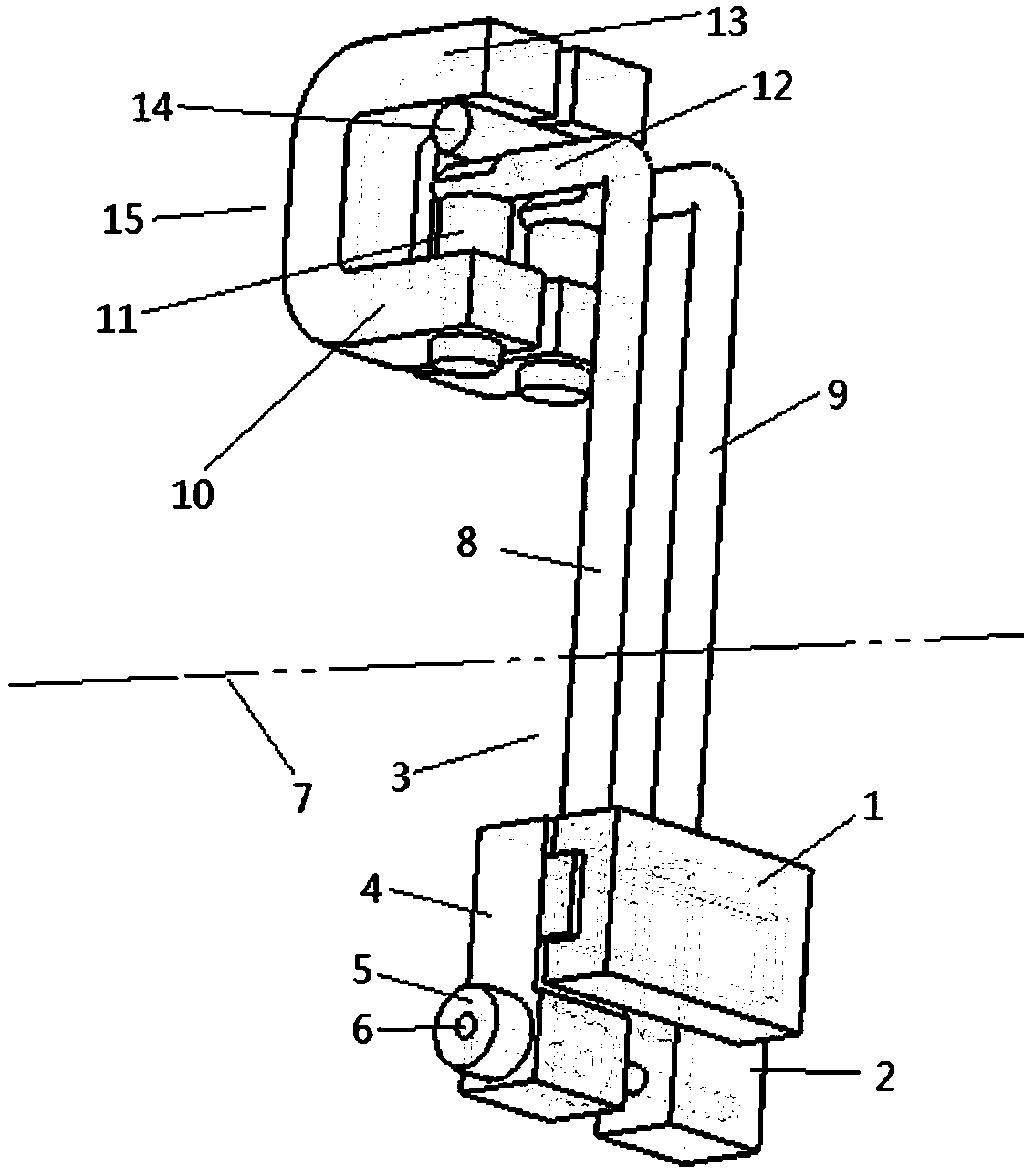

[0013] An example of an anti-creep dilatation instrument figure 2 Shown: It includes a left bracket 4 and a right bracket 2 that can move relatively and oppositely in the left and right directions. The left and right brackets are provided with linear bearings 1 for the left and right brackets to move in the left and right directions. The left and right brackets A displacement sensor for measuring the relative displacement of the left and right brackets is also arranged on the top, the displacement sensor includes a sensor coil 5 arranged on the left bracket and an iron core rod 6 arranged on the right bracket, and the iron core rod 6 passes through the sensor coil Among them, the axes of the iron core rod and the sensor coil extend along the left and right directions. The left bracket 4 is provided with a left clamping assembly for clamping and fixing a sample deformable in the left and right directions, and the right bracket is provided with a right clamping assembly 9 for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com