Load bearing type jacking rod

A technology of ejector rod and rod body, applied in the direction of household components, other household appliances, household appliances, etc., can solve the problems of weak load capacity, easy to fall, single ejector rod structure, etc., and achieve the effect of enhancing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

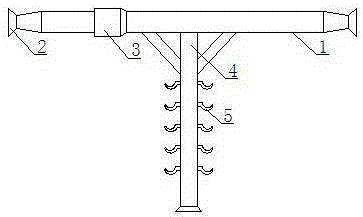

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, a load-bearing ejector rod, including a rod body 1, a plug 2 and a lock nut 3, the plug 2 is connected to both ends of the rod body 1, the lock nut 3 is set in the middle of the rod body 1, and the rod body 1 A pillar 4 is vertically connected to the center of the bottom, and hooks 5 are evenly distributed on the pillar 4 .

[0010] Vertically connect the pillar 4 at the bottom center of the pole body 1, and evenly distribute the hooks 5 on the pillar 4 to form a composite suspension structure. The pillar 4 provides a strong support for the pole body 1, greatly enhancing the load-bearing capacity of the pole body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com