LED (light-emitting diode) down light

A technology of LED downlight and LED light source, which is applied to the loss prevention measures of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc. Excessive concentration of light intensity distribution, etc., to achieve the effect of novel light distribution method, simple and beautiful appearance, uniform and soft reflected light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

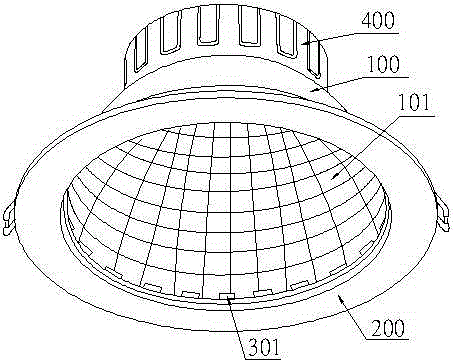

[0012] refer to figure 1 , an embodiment of an LED downlight of the present invention is proposed, which includes a rounded table-shaped lamp housing 100, a face ring 200 connected and fixed on the upper end of the lamp housing 100, fixed on the inner bottom surface of the face ring 200 and facing the lamp housing The LED light source structure illuminated in 100, the drive device box 400 installed at the lower end of the lamp housing 100, and the drive device placed in the drive device box 400 and electrically connected to the LED light source structure.

[0013] The inner surface of the lamp housing 100 is covered with arc-shaped convex surfaces 101 , and the surface of the arc-shaped convex surfaces 101 is coated with a reflective layer capable of reflecting light.

[0014] The LED light source structure includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com