Demountable guide post blanking mould

A blanking die and guide post technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of guide post wear, accuracy reduction, workpiece processing quality decline, etc., to improve service life, ensure strength, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below by specific embodiments:

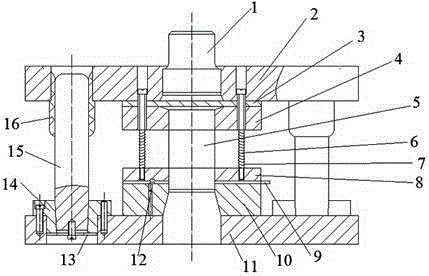

[0014] The reference signs in the drawings include: die handle 1, upper die base 2, backing plate 3, punch fixing plate 4, punch 5, discharge screw 6, discharge spring 7, discharge plate 8, material guide Plate 9 , female die 10 , lower die base 11 , hook stopper pin 12 , washer 13 , bushing 14 , guide post 15 , guide sleeve 16 .

[0015] The example is basically as attached figure 1 As shown, the detachable guide column blanking die includes an upper die part, an elastic pressure discharge part, a lower die part, and a guide part. The upper die part includes a die handle 1, an upper die seat 2, a gasket 3, and a punch fixing plate 4 and the punch 5, the elastic pressure discharge part includes the discharge screw 6, the discharge spring 7 and the discharge plate 8, the lower die part includes the guide plate 9, the female die 10, the lower die base 11 and the hook-shaped stopper pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com