Snow removal truck

A technology for snow plows and trolleys, which is applied to snow cleaning, construction, cleaning methods, etc. It can solve the problems of potential safety hazards, time-consuming and labor-intensive snow plowing, and relying on manpower for snow plowing to achieve high-efficiency snow plowing and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

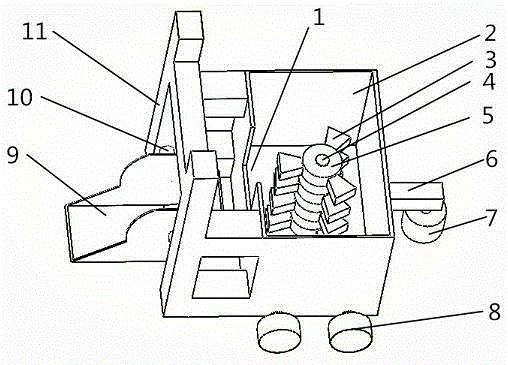

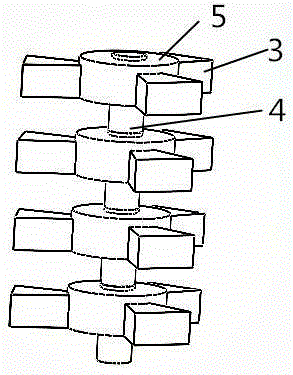

[0020] A snowplow of the present invention comprises: the interior of the snow storage box is hollow, a snow inlet 1 is opened in the front, and a bracket 11 is fixedly connected to the front of the snow storage box 2; the bracket 11 is in the shape of a "door", and the bracket 11 is fixed In front of the box body, a first rotating shaft 10 is fixed below the bracket 11; the snow shovel 9 passes through the first rotating shaft 10, and rotates with the rotation of the first rotating shaft 10; the air outlet 7 is cylindrical The air outlet is fixedly connected to the rear wall of the snow storage box 2 through the air outlet channel 6; the second rotating shaft 4 is installed on the bottom surface of the snow storage bucket 9 along the vertical direction, and a turntable 5 is fixedly installed on the second rotating shaft 4. Three rotors 3 are fixedly installed on the turntable 5, and the three rotors 3 are arranged on the turntable in sequence at 120 degrees; there are four whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com