Spliced hollow brick

A hollow brick and gap technology is applied in the direction of paving, roads and building components paved with prefabricated blocks, which can solve the problems of non-tight mutual structure, inconvenient walking for passers-by, and easy loosening of hollow bricks, so as to achieve the effect of not easy to dislocate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

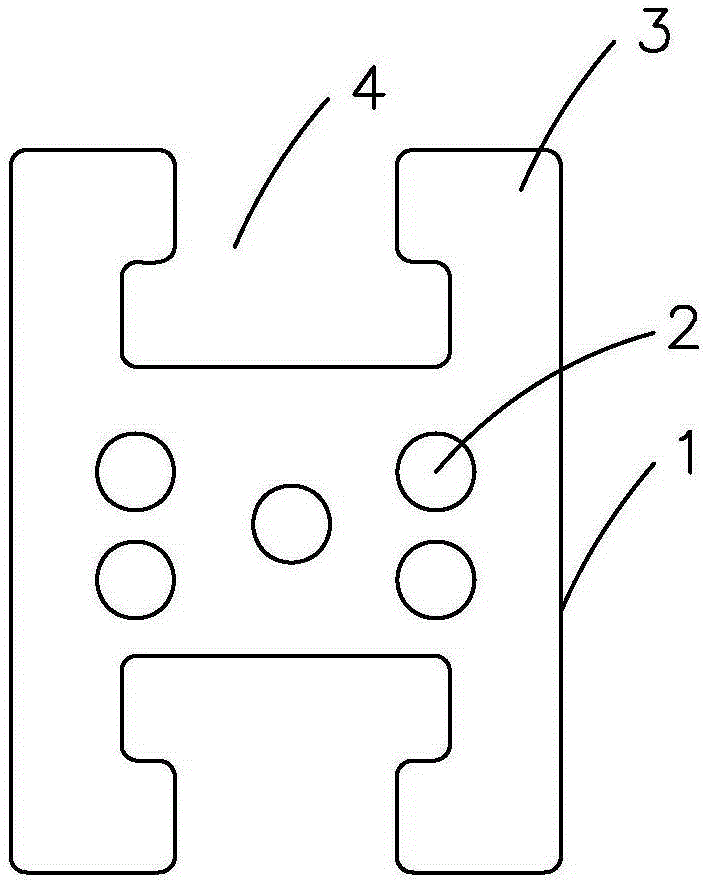

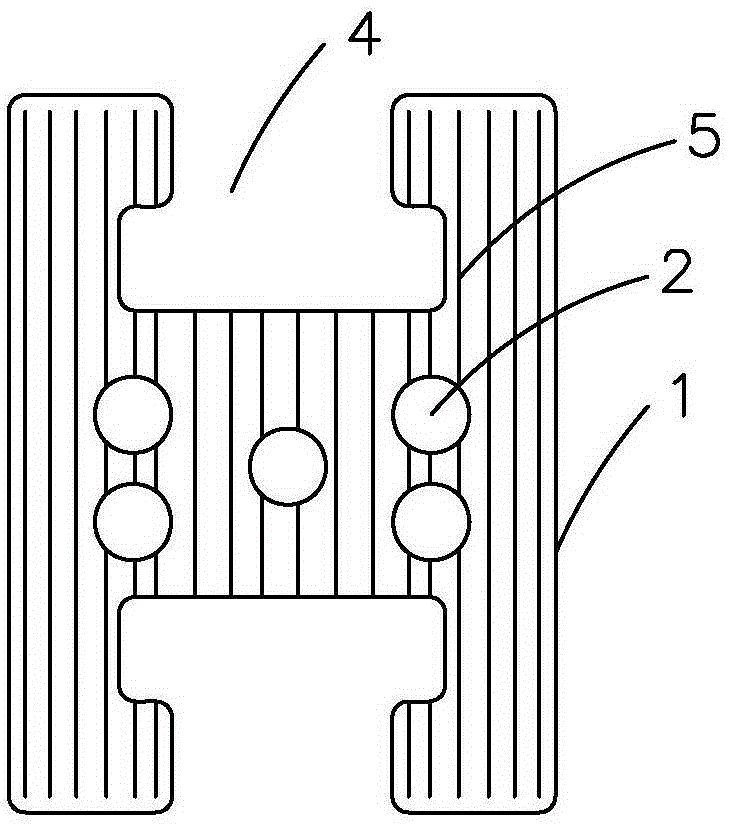

[0018] Such as figure 1 As shown, a splicing hollow brick is characterized in that: it includes a main body 1, and the upper and lower sides of the main body 1 are symmetrically provided with a "T"-shaped gap 4; the "T"-shaped gap 4 is formed by two left and right "L" convex walls 3 Enclosed; the shape of the combination of the convex walls 3 of the two different hollow bricks matches with the "T"-shaped gap 4; the back of the hollow bricks is provided with strip-shaped corrugations. In order to make the hollow bricks more firmly bonded to the ground, or to make the ground plants grow from the hollow bricks to make the walking path more beautiful, the main body 1 is uniformly provided with through holes 2 inside.

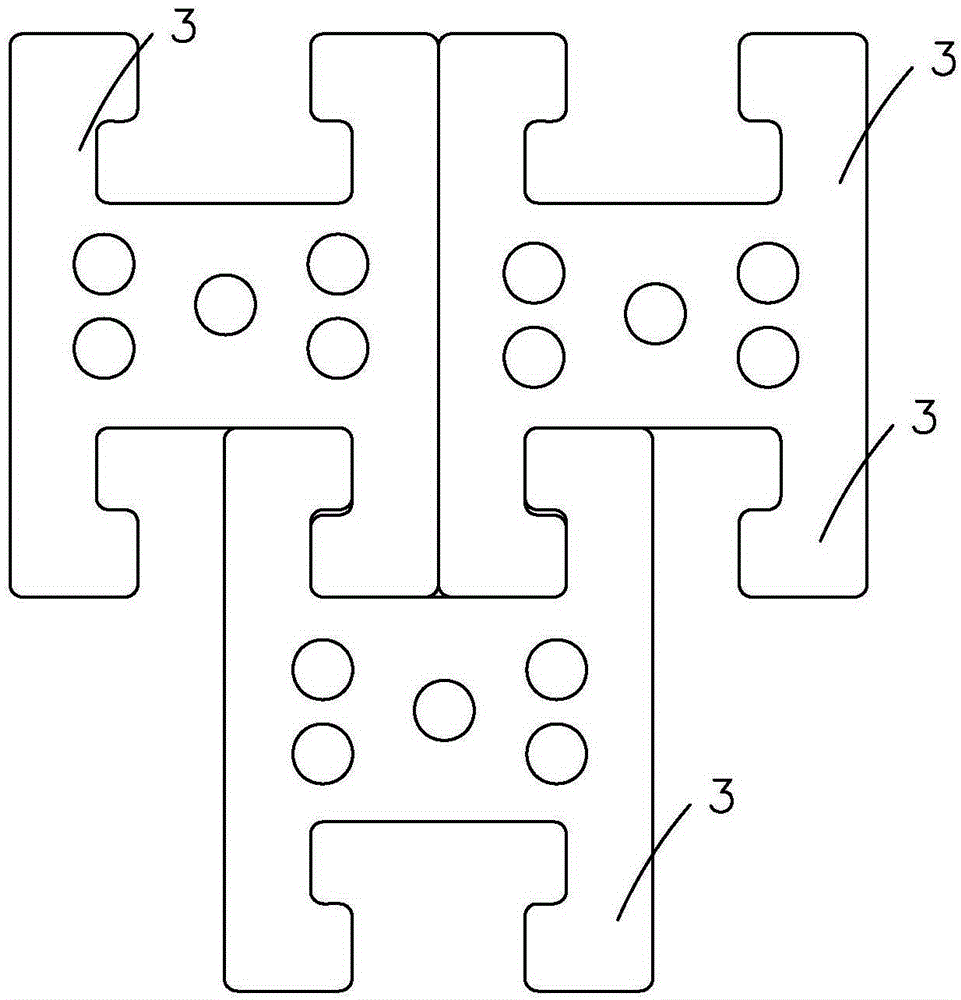

[0019] Such as figure 2 As shown, when the hollow brick is laid, in order to avoid damage to the inner wall of the convex wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com