Method for controlling bulging deformation of valve-regulated lead-acid (VRLA) storage battery

A technology of lead-acid batteries and control valves, which is applied in the direction of lead-acid batteries, lead-acid battery construction, secondary batteries, etc., can solve the problems of battery safety hazards, negative impact on the economy, battery deformation, etc., to avoid economic losses, The effect of reducing the amount of thermal deformation and reducing the internal air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

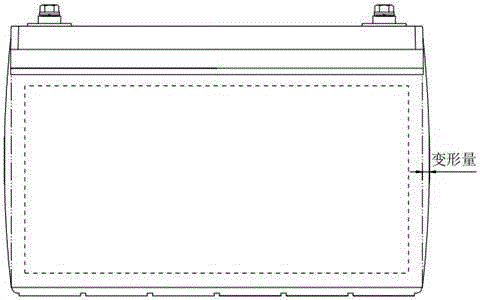

Image

Examples

example 1

[0019]Example 1: Production of 12V180Ah batteries, the assembly compression ratio of the pole group is 20%; in the process of adding electrolyte to the battery, the battery is first cooled at low temperature, and the assembled battery is placed in a freezer at a temperature lower than 0°C for 4 hours. Take out the cooled battery and add electrolyte immediately. The temperature of the electrolyte is cooled to 13°C by cooling acid machine; the temperature of the water bath in the battery forming process is controlled at 20°C; Safety valve; After holding the valve and standing for 72 hours, the bulging deformation of the battery is detected to be 0.8mm.

example 2

[0020] Example 2: Production of 12V1800Ah batteries, the assembly compression ratio of the pole group is 25%; in the process of adding electrolyte to the battery, the battery is first cooled at low temperature, and the assembled battery is placed in a freezer with a temperature below 0°C for 15 hours. Take out the cooled battery and add electrolyte immediately. The temperature of the electrolyte is cooled to 13°C by cooling acid machine; the temperature of the water bath in the battery formation process is controlled at 25°C; Put on the safety valve; after the valve is closed, let it stand for 72 hours, and then detect the battery swelling deformation of 1.0mm.

example 3

[0021] Example 3: In the production of 12V1800Ah batteries, the assembly compression ratio of the pole group is 23%; in the process of adding electrolyte to the battery, the battery is first cooled to a low temperature, and the assembled battery is placed in a freezer at a temperature lower than 0°C for 10 hours. Take out the cooled battery and add electrolyte immediately. The temperature of the electrolyte is cooled to 14°C by cooling acid machine; the temperature of the water bath in the battery formation process is controlled at 30°C; Safety valve; After holding the valve and standing still for 72 hours, the bulging deformation of the battery is detected to be 1.8mm. Use the vacuum equipment installed in the acid adding machine to pump air out of the battery, detect the deformation of the battery during the pumping process, and stop the pumping when the deformation of the battery is less than 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com