Pneumatic tire

一种充气轮胎、轮胎的技术,应用在重型轮胎、轮胎零部件、胎沿等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

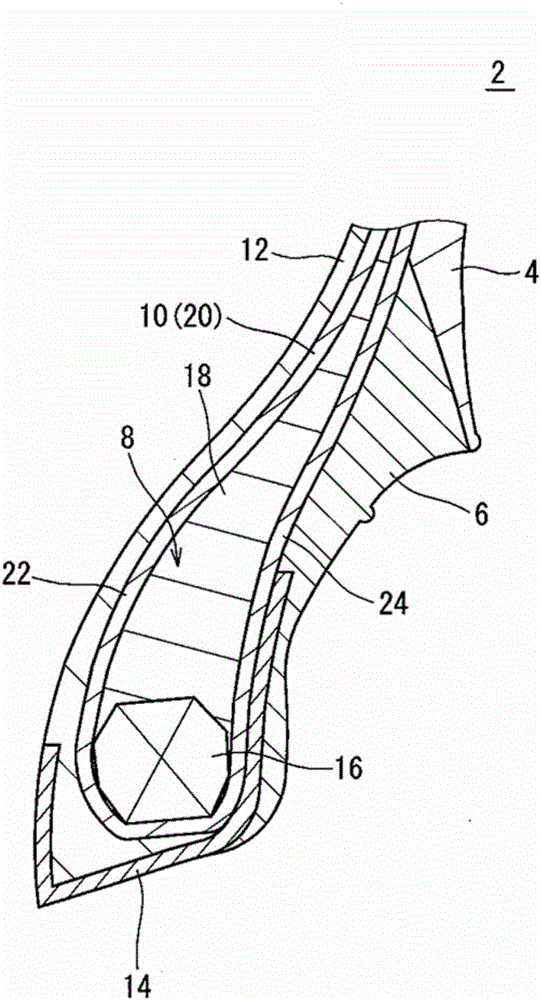

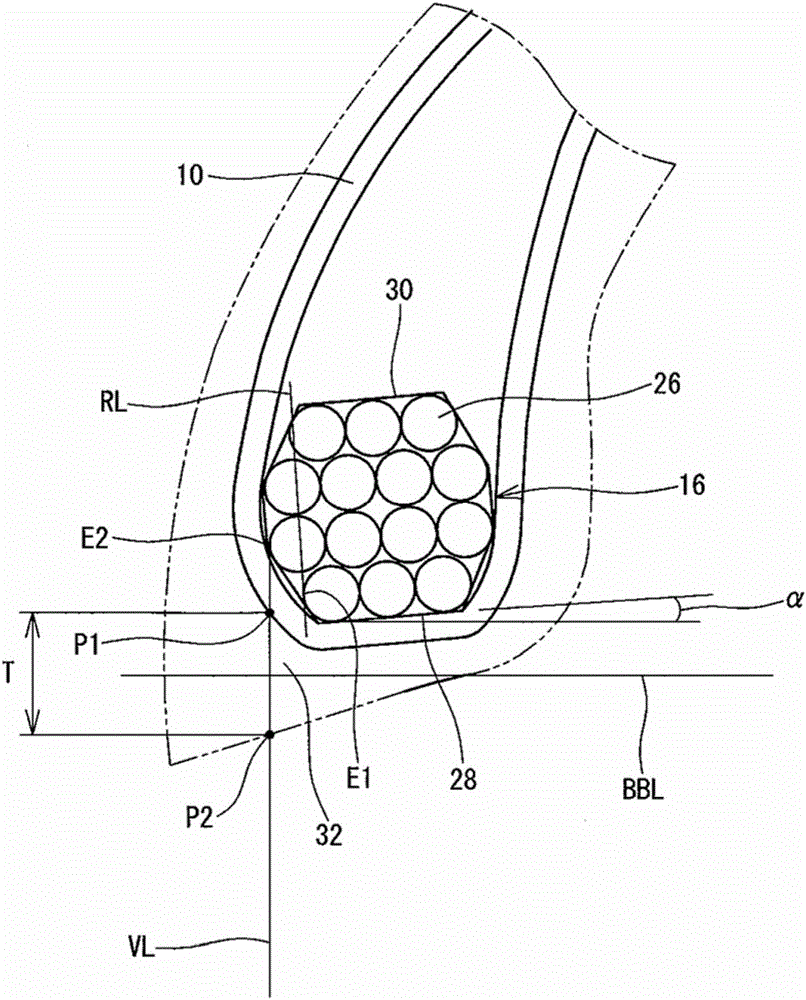

[0072] made with figure 1 The tire of Example 1 of the configuration shown in and the specifications indicated in Table 1 below. The tire has a size of 205 / 40R16. This tire has figure 2 The core structure shown in . This is indicated in the cell of the core structure in Table 1 as " figure 2 ". The angle between the bottom edge of the core and the bead base line BBL is 5°. This is indicated in the cell Core Angle α in Table 1.

example 2

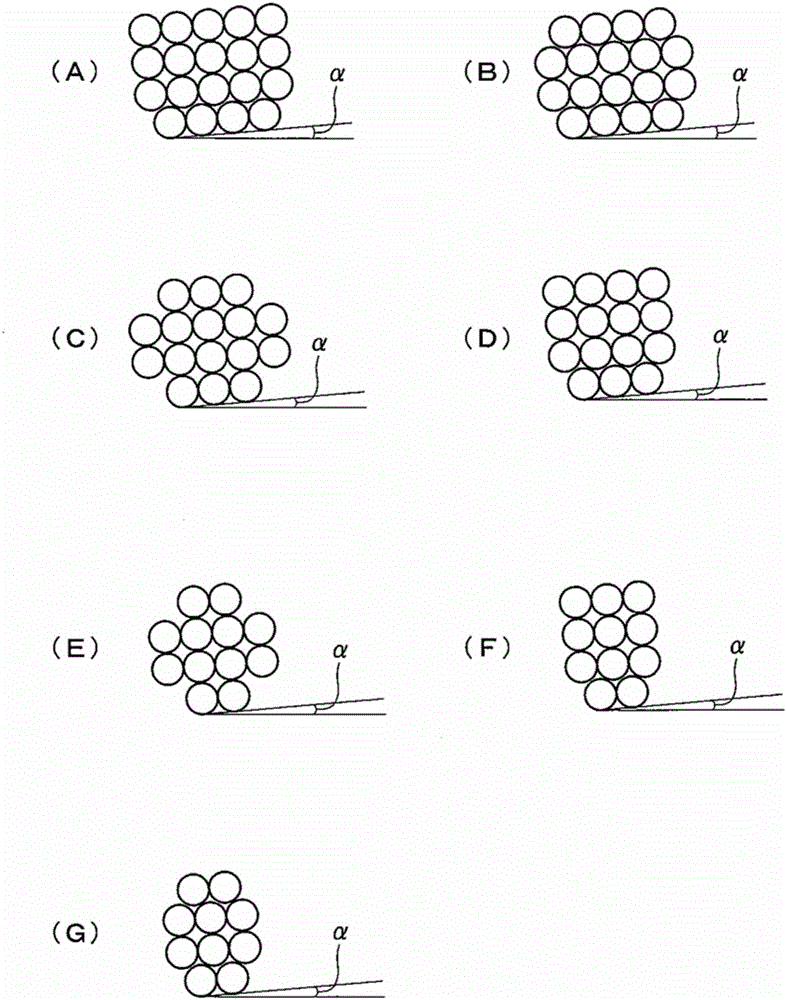

[0080] The core structure is image 3 Except for the core structure shown in (A), a tire of Example 2 was produced in the same manner as Example 1.

example 3

[0082] The core structure is image 3 Except for the core structure shown in (B), a tire of Example 3 was produced in the same manner as Example 1.

[0083] [Comparison of Examples 4 to 6 and Examples 4 to 5]

[0084] Tires of Comparative Examples 4 to 6 and tires of Examples 4 to 5 were produced in the same manner as Example 3 except that the core angle α was as indicated in Table 2.

[0085] [Example 6 to 10]

[0086] Tires of Examples 6 to 10 were produced in the same manner as Example 1 except that the core structure was as indicated in Table 3.

[0087] [Comparison of Examples 7 to 8 and Examples 11 to 14]

[0088] Tires of Comparative Examples 7 to 8 and tires of Examples 11 to 14 were produced in the same manner as Example 1 except that the thickness T inside the core was as indicated in Table 4.

[0089] 【Tightening Force Gradient】

[0090] The tightening force gradient was measured using the method specified by Wdk116 (German Rubber Industry Association). The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com