Limb splint and manufacturing method thereof

A technology of splints and limbs, applied in medical science, fractures, etc., can solve the problems of uncomfortable wearing, cumbersome operation, and manpower occupation for patients, and achieve the effect of comfortable and convenient wearing, good curvature adaptability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

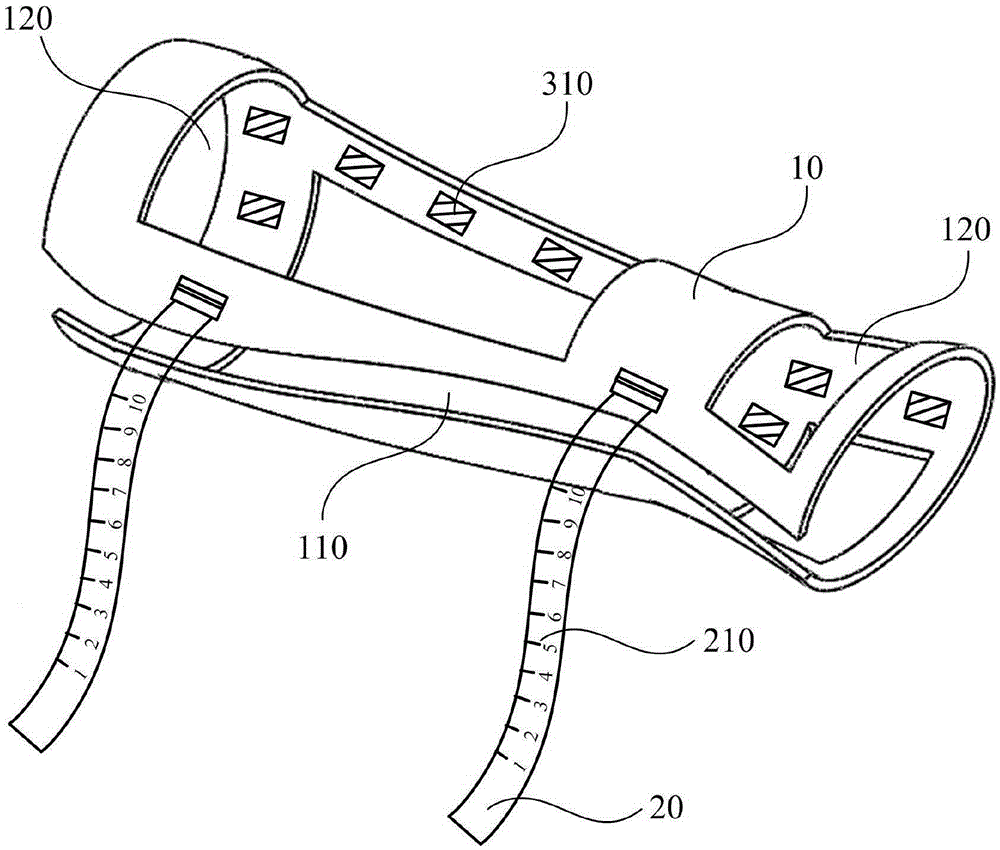

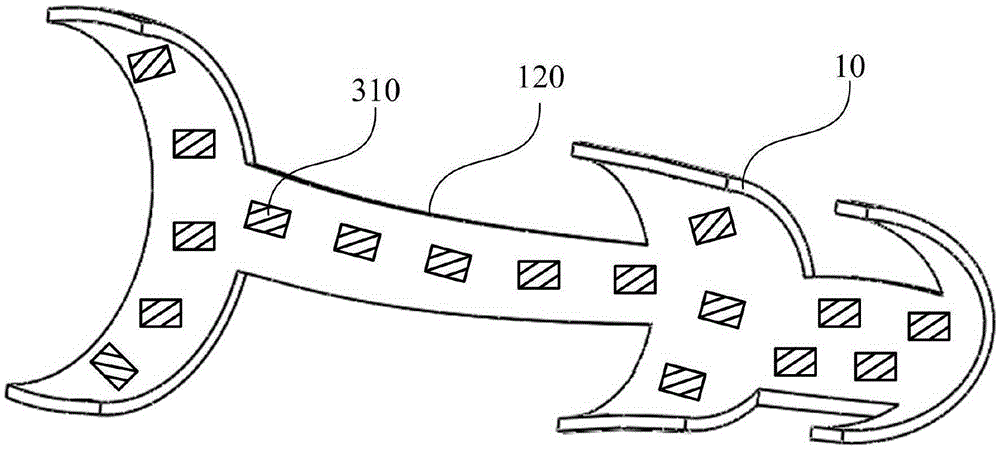

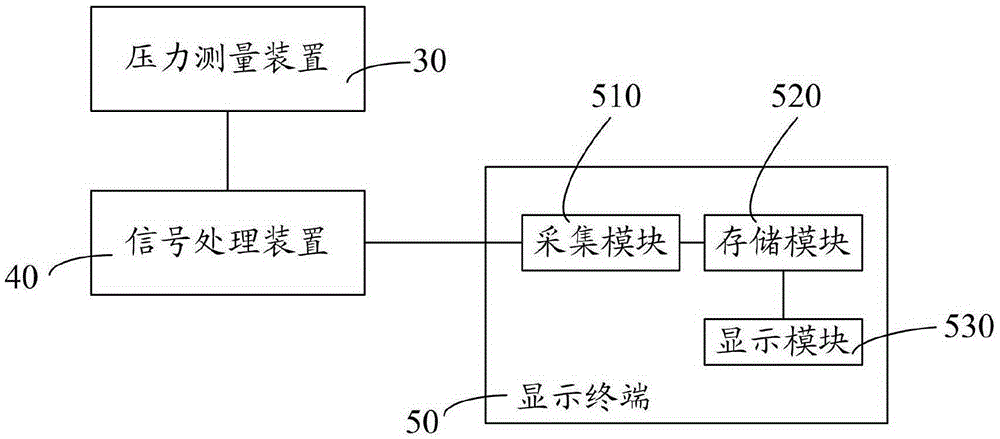

[0032] Such as figure 1 , figure 2 As shown, a limb splint includes a curvature splint 10 and a winding belt 20. The curvature splint 10 is a hollow cylindrical structure with two ends open, and the curvature of the side wall of the curvature splint 10 matches the curvature of the surface of the limb installation site. An axial adjustment channel 110 is opened on the side wall of the curvature splint 10 , and the curvature splint 10 is connected and fixed by the wrapping belt 20 to form surrounding pressure on the limb. Wherein, the wrapping belt can be fixed on the curvature splint 10 , or exist independently without being connected to the curvature splint 10 . The curvature of the side wall of the curvature splint 10 matches the curvature of the limb installation site, and an adjustment channel 110 is provided on the side wall of the curvature splint 10. When the patient's limb is actually fixed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com