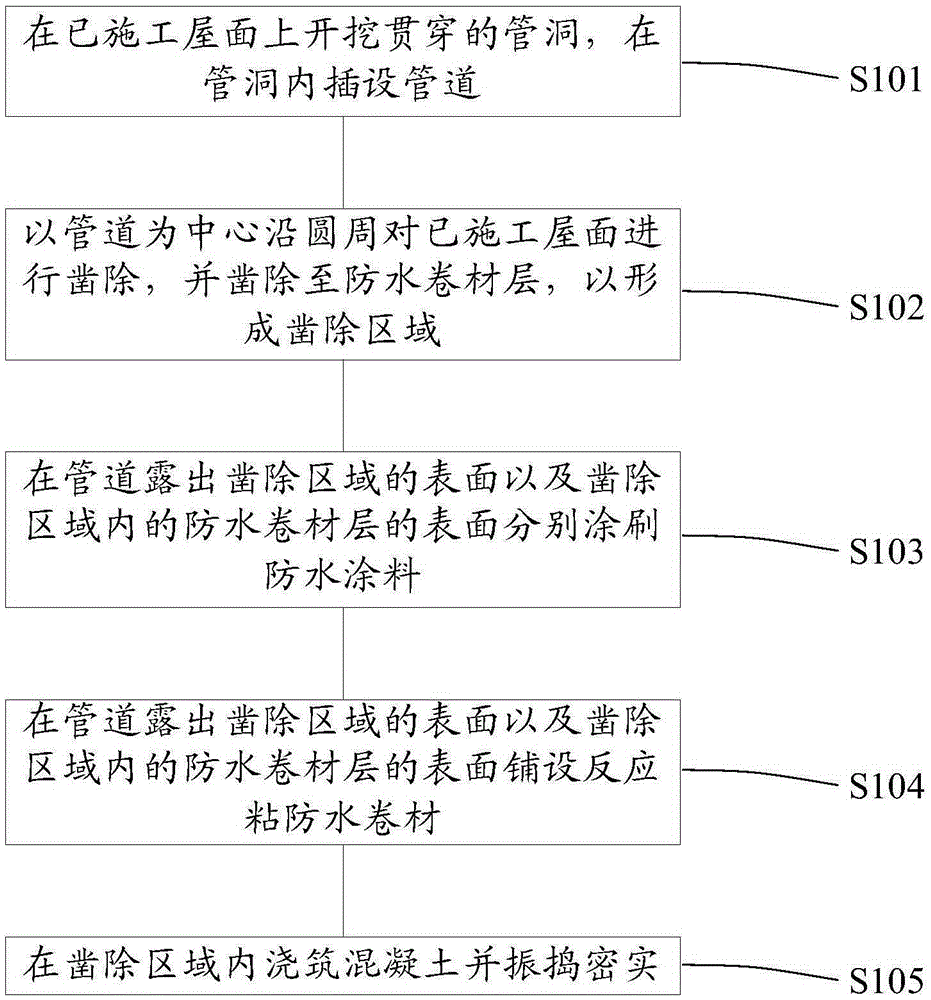

Construction method for restoration of secondary hole excavation in constructed roof for pipeline penetration

A construction method and post-hole technology, which is applied in snow traps and other directions, can solve the problems of damaging the waterproof layer, cracking, and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

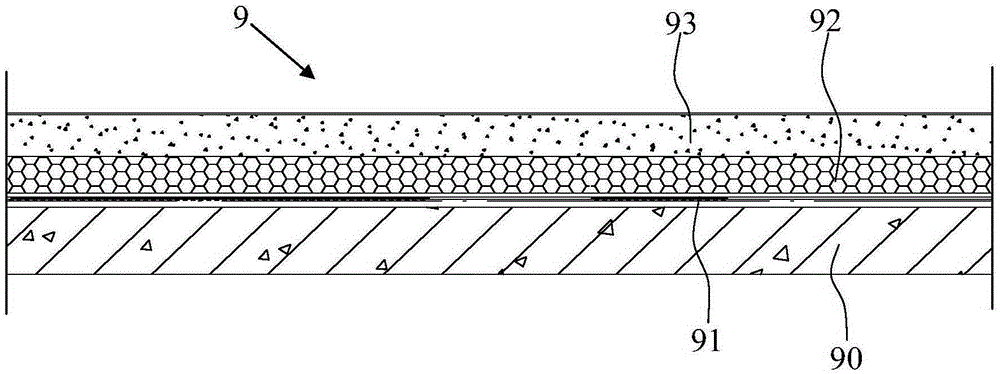

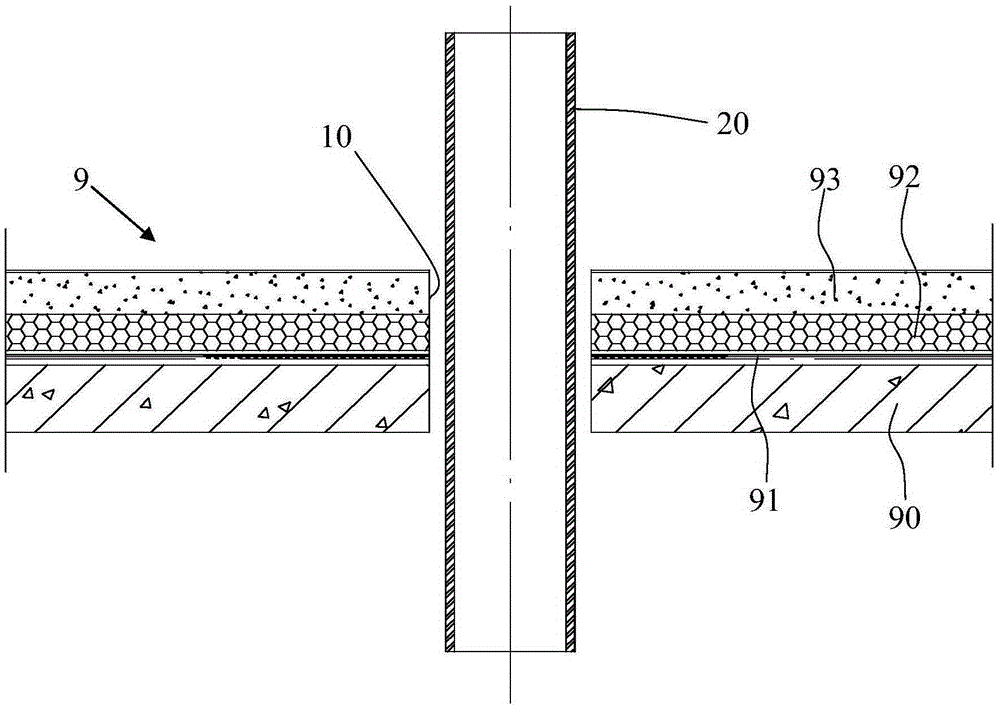

[0031] First, with reference to figure 2 as shown, figure 2 It is a schematic diagram of the structure of the constructed roof according to the construction method of opening holes and piercing pipes for repairing the constructed roof. In the construction method of the present invention for repairing the constructed roof by opening holes and piercing pipes, the constructed roof 9 includes a waterproof coiled material layer 91 , an insulation board layer 92 and a concrete layer 93 arranged on the structural roof panel 90 from bottom to top. Among them, the structural roof panel 90 is pounded and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com