A heat storage peak-shaving device for a heating system

A heating system and heat storage technology, used in heating systems and central heating, can solve the problems of narrowing the temperature difference between the inlet and return water of the system, unstable return water temperature, high operation and maintenance costs, and eliminate the severe end load. The effect of fluctuation, realization and promotion of behavioral energy saving, low cost of heat transmission and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

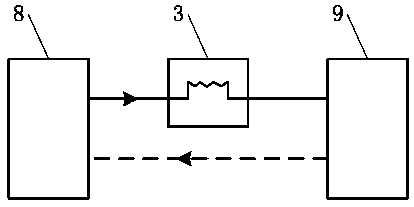

[0062] When the thermal storage peak-regulating device of the present invention is applied to the heat source end (such as a central heating boiler), the primary system mode (such as Figure 5 (Shown), the system includes: a heat source 8, a user end system 9, and the heat storage / heat exchange module 3 is arranged between the heat source 8 and the user end system 9;

[0063] On the water supply end of the heat source 8, one or a group of regulating valves F1 and the water supply section crossover pipe 11 are set, and one or a group of regulating valves F2 and the return water section crossover pipe 12 are set on the return water end of the heat source 8; the connection sequence is :

[0064] Heat source 8→heat source water supply end→regulating valve F1→heat storage / heat exchange module 3 in the water supply section heat exchange pipe 1 / water supply section crossing pipe 11→heating pipe network→user terminal system 9→heating pipe network→regulating valve F2→ The backwater section ...

Embodiment 2

[0074] The existing building heat exchange station cancels the secondary network and uses the primary network to directly connect to the building (see reference 3). The system consists of a plate heat exchanger system and a building variable flow control system, of which the cost of the building variable flow control system is relatively high.

[0075] The two-level system mode of the present invention can be used to replace the building variable flow control system and reduce the cost. The system includes: heat source 8, primary water supply pipe 13, primary return water pipe 14, primary / secondary heat exchanger 15, secondary water supply pipe 16, secondary return water pipe 17, user terminal system 9, heat storage / heat exchange module 3 settings Between the heat source 8 and the end system 9; the primary / secondary heat exchanger 15 is a partition heat exchanger, which can be a plate heat exchanger, a tube heat exchanger or a fin heat exchanger. When the system is running, the ...

Embodiment 3

[0089] The device of the present invention can be directly applied to end users. For example, in a household-divided ring heating system, the device of the present invention is installed at the thermal entrance of the end user. Because the situation of the end user terminal system is more complicated, users should be provided with a flexible system to adapt to different application environments. Such system settings also provide convenience for users' behavioral energy saving.

[0090] Here, the structure of "Mode 2" described in the Summary of the Invention is adopted:

[0091] The heat storage / heat exchange module 3 is divided into at least two modules, namely the first heat exchange module 3a and the second heat exchange module 3b. The first heat exchange module 3a and the second heat exchange module 3b are both equipped with heat storage bodies, The heat storage body adopts a phase change heat storage material, wherein the phase change temperature T of the heat storage body in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com