Two-side flow variable sewage source heat pump unit and operation method thereof

A sewage source heat pump and flow technology, which is used in heat pumps, fluid heaters, refrigerators, etc., can solve the problems of high requirements for intermediate heat exchangers, low efficiency, and high requirements for sewage treatment, so as to increase the temperature difference between incoming and outgoing water, work Clear principle and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

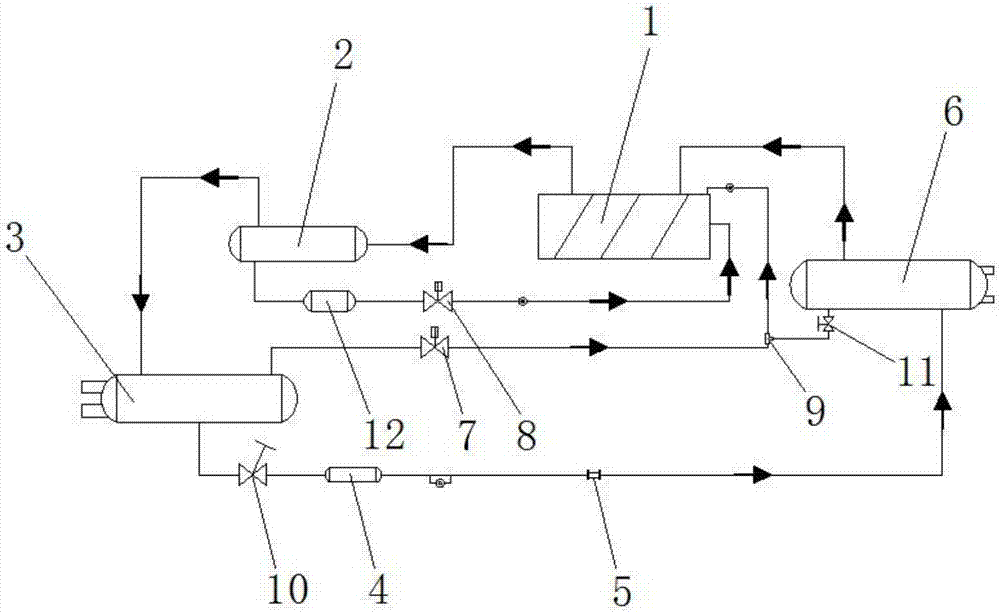

[0024] Such as figure 1 As shown, a double-sided variable flow sewage source heat pump unit includes connecting pipelines; the sewage source heat pump unit consists of a screw heat pump compressor 1, an oil separator 2, a variable flow condenser 3, a dry filter 4, and an electronic Expansion valve 5, variable flow flooded evaporator 6, evaporator oil return solenoid valve 7, oil separation oil return solenoid valve 8, ejector pump 9, liquid circuit stop valve 10, evaporator oil return stop valve 11 and oil filtration The devices 12 are connected to each other by connecting pipelines;

[0025] Such as figure 1 As shown, a double-sided variable flow sewage source heat pump unit, screw heat pump compressor 1, oil separator 2, variable flow condenser 3, electronic expansion valve 5 and variable flow flooded evaporator 6 are connected in series connection; between the screw h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com