Developing box

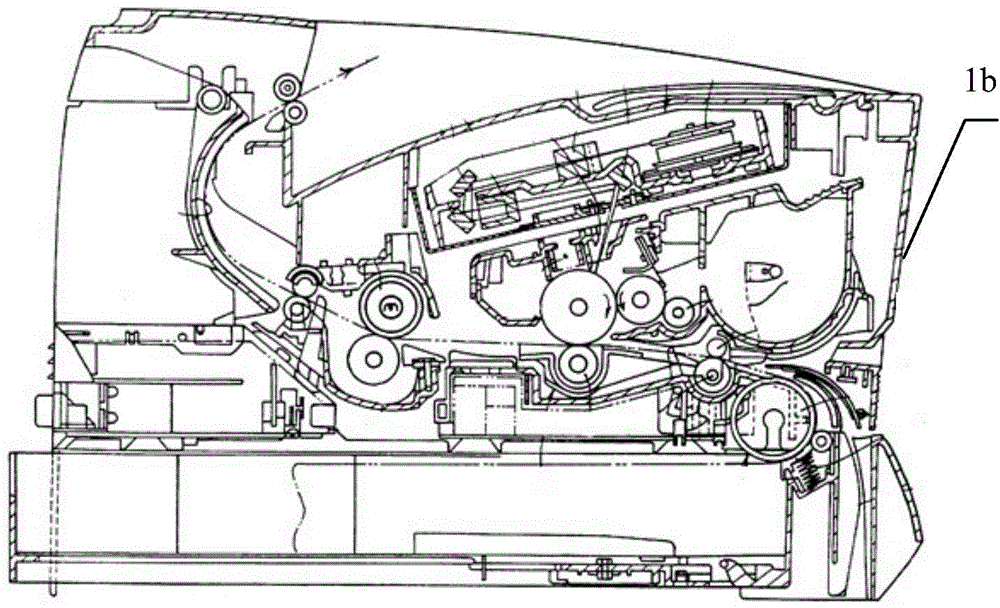

A developing cartridge and cartridge body technology, which is applied in the field of detection, can solve the problems of damage to the detection part, collision of other parts of the main body of the developing cartridge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

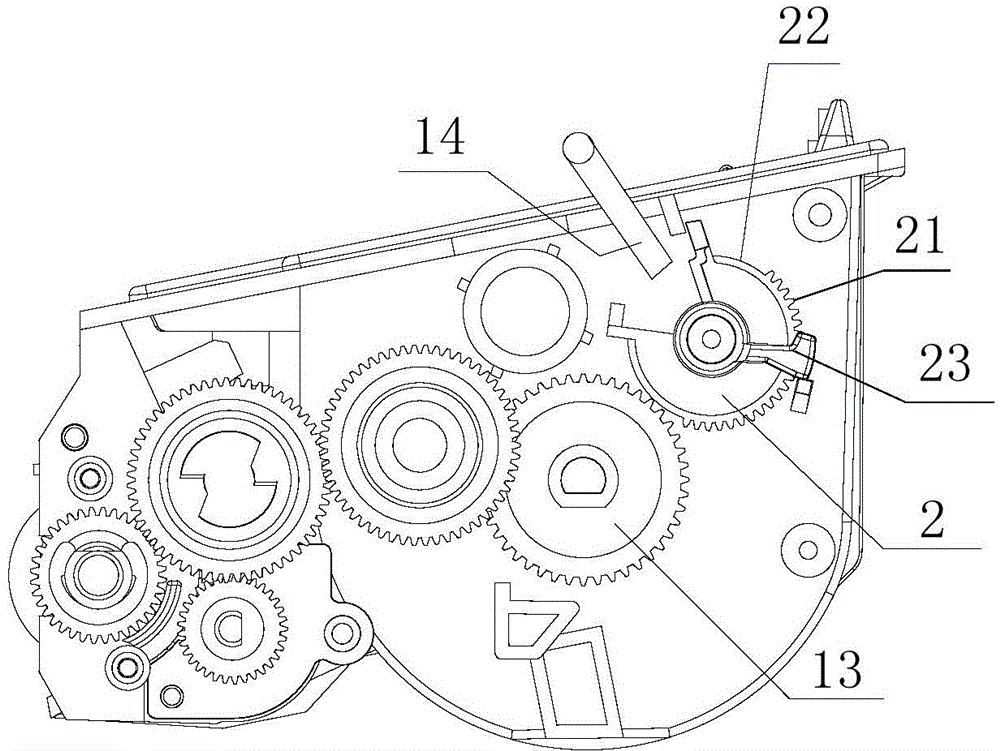

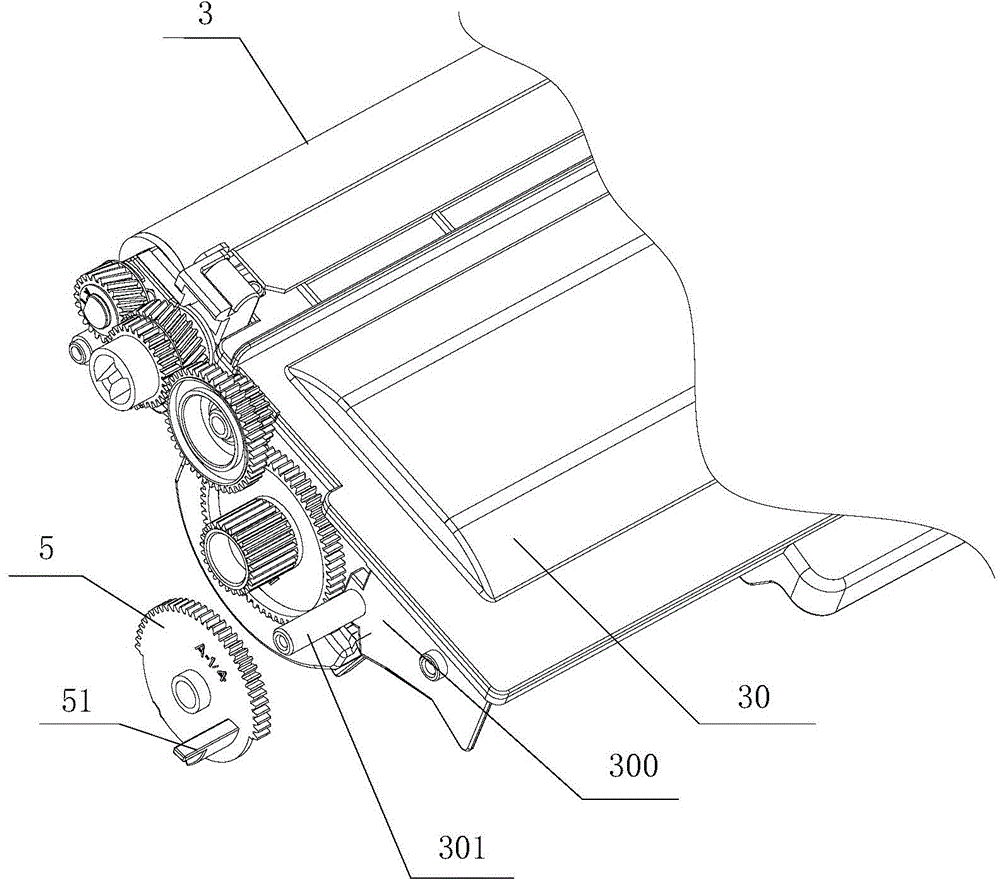

[0057] image 3 It is a structural schematic diagram of an embodiment of the shadow cartridge of the present invention, Figure 4 It is a structural schematic diagram of the detection gear in the shadow cartridge of the present invention, as Figure 3-4 As shown, the developing cartridge 3 includes: a box body 30, a detection gear 5, the detection gear 5 is arranged on the box body 30, and the detection gear 5 includes a detection protrusion 51, a gear portion (toothed segment) 52, a missing tooth portion (toothless segment) ) 53 and mounting cylinder 54, the developing cartridge 3 also includes: a control assembly, the control assembly is used to control the axial movement of the detection gear 5 along the detection gear 5, wherein the detection gear 5 can be arranged on the box body 30, or can be arranged on On the side wall of the box body 30, in this embodiment, such as image 3 As shown, the detection gear 5 is arranged on the side wall 300 of the box body, specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com