The leather of the outer leather of an earmuffs is pulled by the cutting mechanism of the cutting mechanism

A cutting mechanism and leather material technology, applied in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, etc., can solve poor cutting effect and low efficiency and other problems, to achieve the effect of convenient cutting, firm fixation and no wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

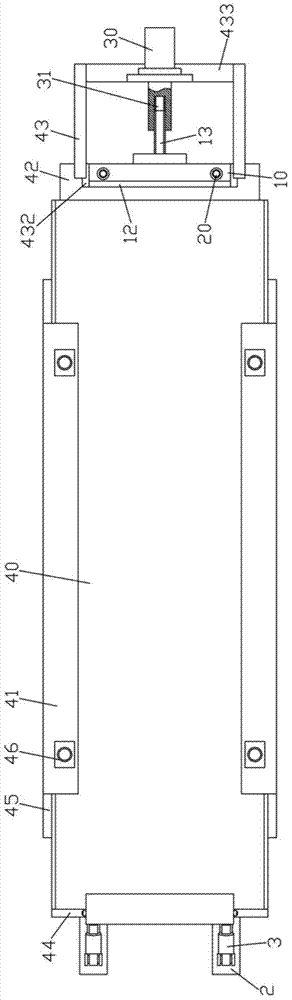

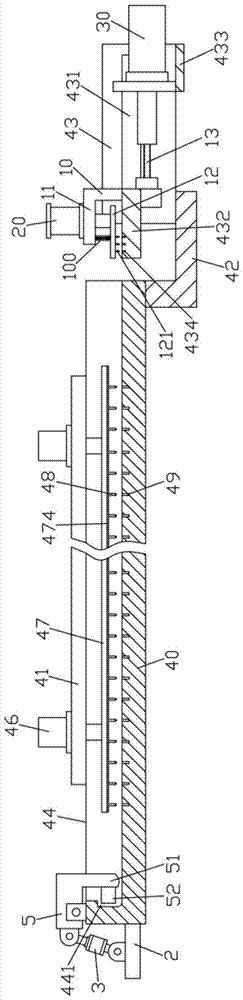

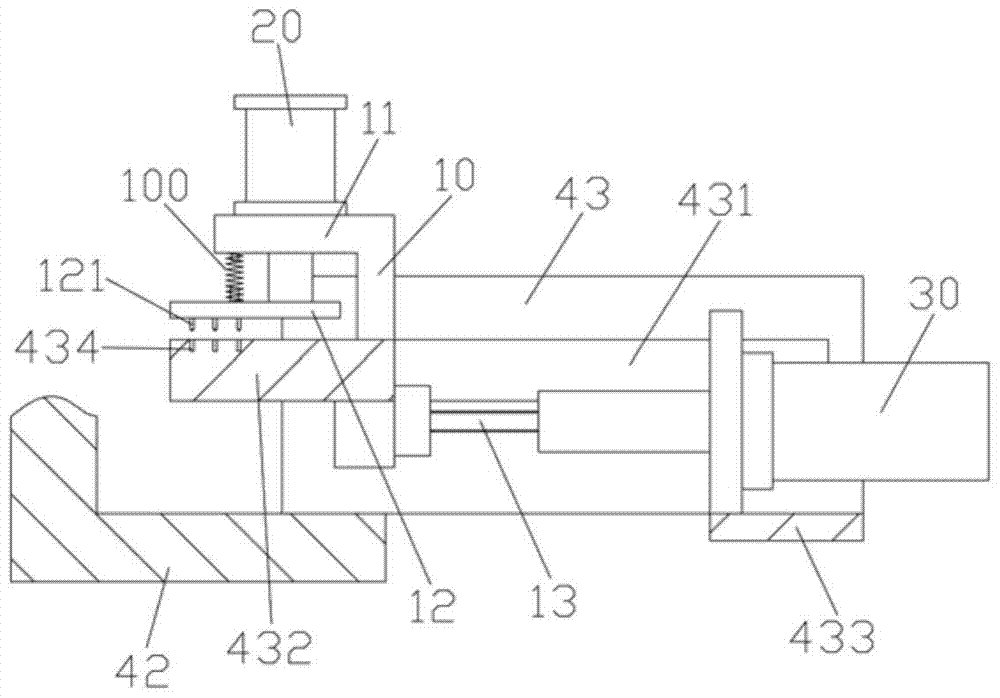

[0021] Examples, see e.g. Figure 1 to Figure 3 As shown, a leather material feeding and straightening mechanism of a cutting mechanism for the outer skin of earmuffs includes a leather placing plate 40, and the left side, the front side and the rear side of the top surface of the leather placing plate 40 have upwardly extending The sidewall 44 of the leather material placement plate 40 is fixed with a connecting plate 45 at the left and right ends of the front side and the left and right ends of the rear side. The connecting plate 45 is fixed with a horizontal elongated plate 41, and the horizontal elongated plate 41 A plurality of compression cylinders 46 are fixed on the top, and the push rods of the compression cylinders 46 pass vertically downward through the horizontal elongated plate 41 and are fixed with a briquetting block 47, which is above the leather material placement plate 40;

[0022] The bottom right side of the leather material placement plate 40 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com