Limiting structure of dumper front telescopic sleeve hydraulic cylinder

A limit structure, telescopic technology, applied in the direction of fluid pressure actuation device, inclined load-carrying vehicles, etc., can solve the problems of cylinder inner wall deformation, limit valve failure, seal damage, etc., to achieve reasonable positioning structure, Guaranteed reliability and stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

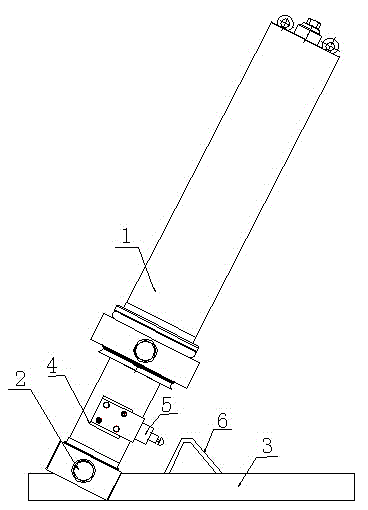

[0012] The present invention as figure 1 shown.

[0013] The limit structure of the front telescopic sleeve hydraulic cylinder of the dump truck includes the main body 1 of the front telescopic sleeve hydraulic cylinder of the dump truck. A limit valve 5 is installed on the side of the lower part of the cylinder body 1 through a limit valve bracket 4, and a baffle plate 6 is arranged on the sub-beam 3 corresponding to the top of the limit valve 5, so that the two become a reverse limit structure.

[0014] The baffle plate 6 is an inverted "V"-shaped structure, and is fixed on the sub-beam 3 by using two divergent bottom edges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com