Rotating electrical machine

A technology of rotating electrical machines and rotating axes, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., and can solve problems such as the performance degradation of rotating electrical machines and the reduction in the number of turns of coil wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described below with reference to the drawings.

[0031] basic configuration

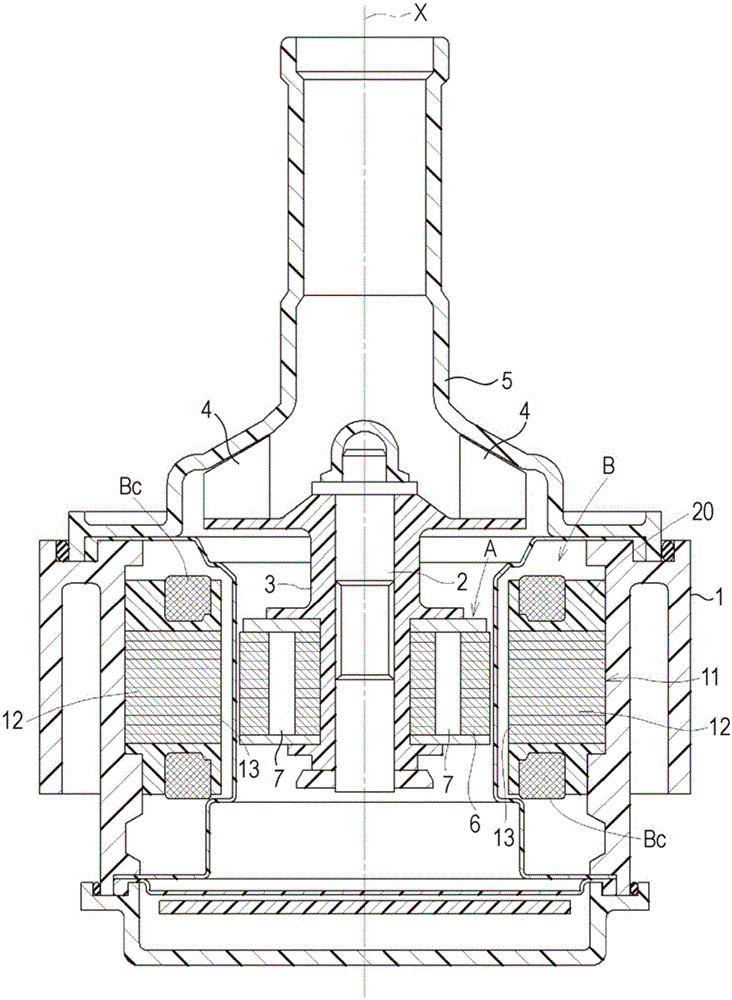

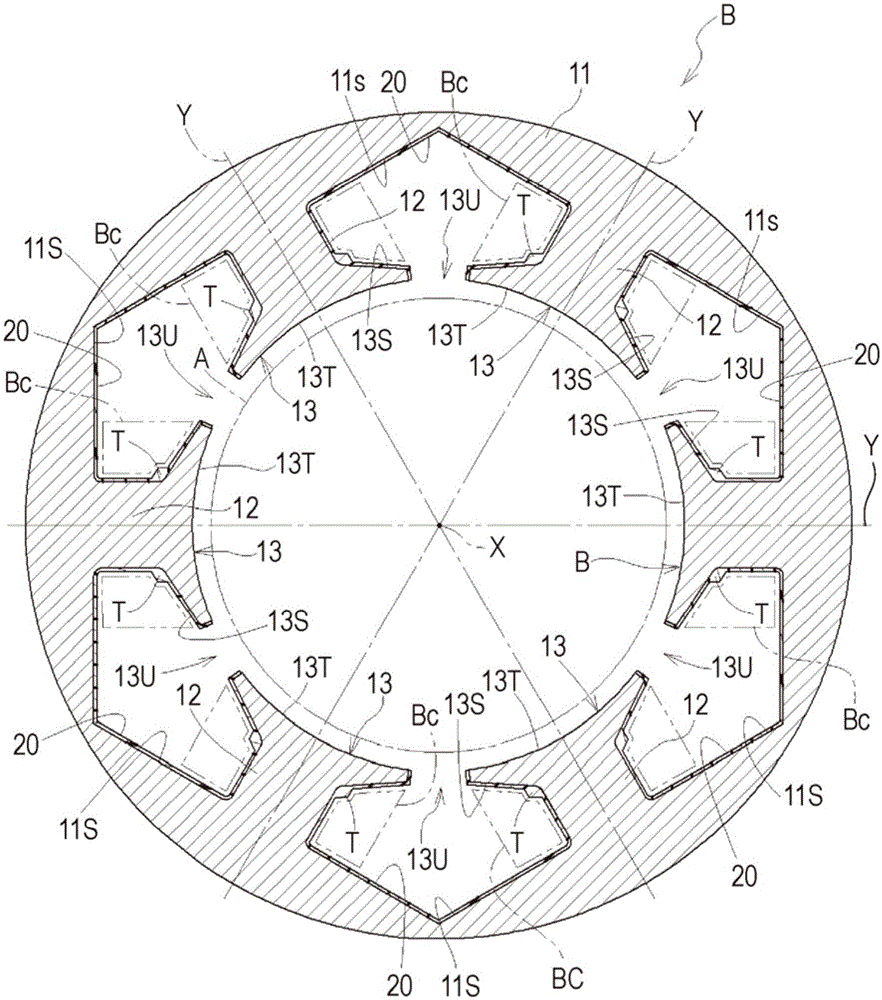

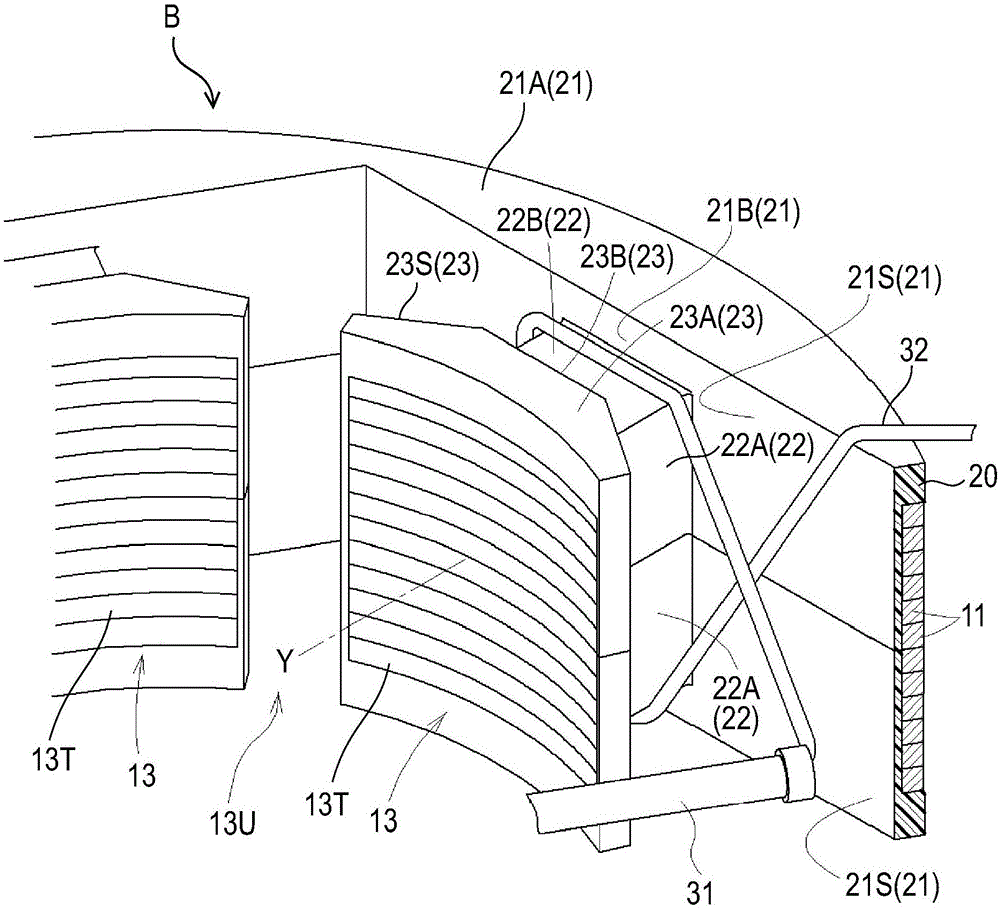

[0032] Such as figure 1 As shown in , a brushless motor as a rotating electrical machine is configured to include: a support shaft 2 whose both ends are supported in a casing 1 coaxially with the rotation axis X; rotatable on the outer surface; a rotor A that rotates integrally with the rotating shaft 3; and a stator B that is disposed in an area surrounding the rotor A.

[0033] The rotary shaft 3 is made of resin, and a pusher 4 is integrally formed at the end of the rotary shaft 3 . This electric motor is used in a water pump that circulates coolant around an inverter or circulates coolant between an engine and a radiator in a passenger car or the like in a state where a propeller 4 of the electric motor is accommodated in a water pump housing 5 middle.

[0034] A brushless motor is taken as an example of the rotary electric machine; however,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com