A lockable CD box

An optical disc box and locking technology, applied in the field of optical disc storage, can solve the problems of disc wear, damage, loss of information, etc., and achieve the effect of improving the stability of transportation and improving the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

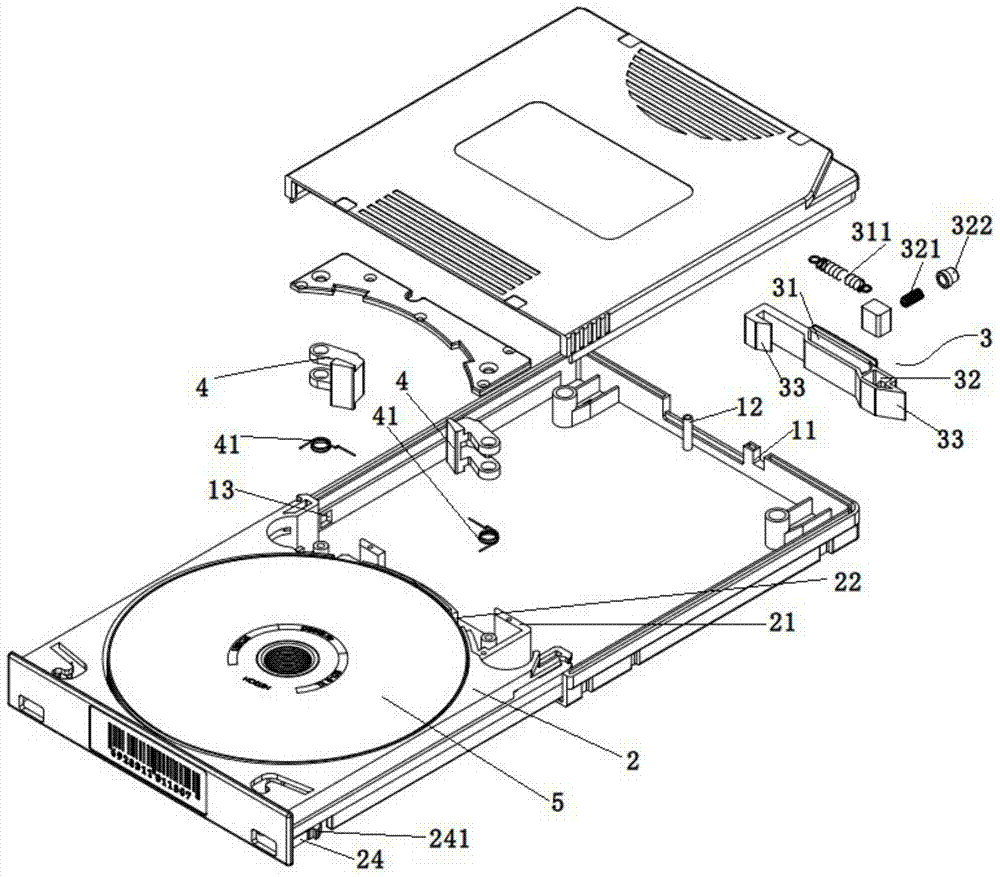

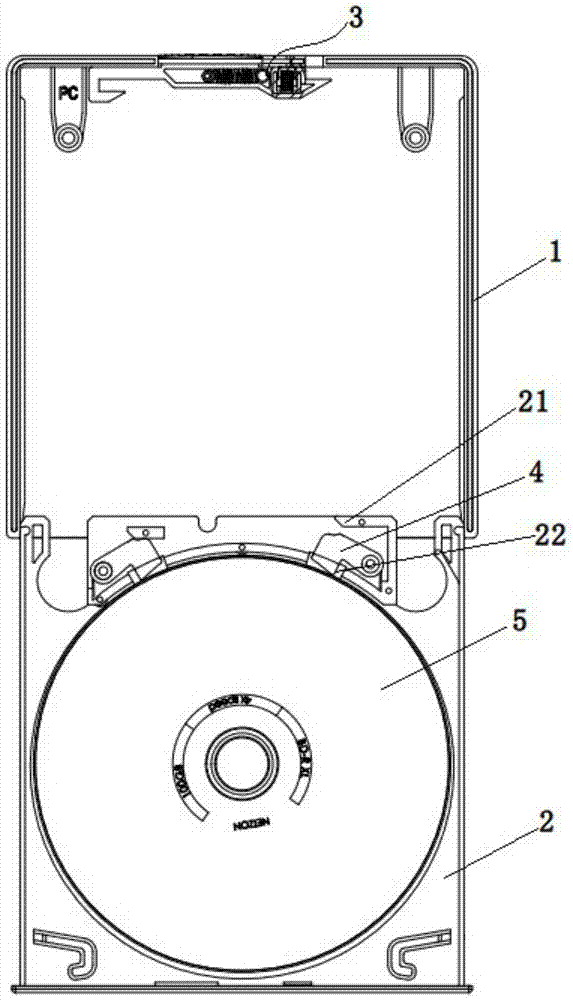

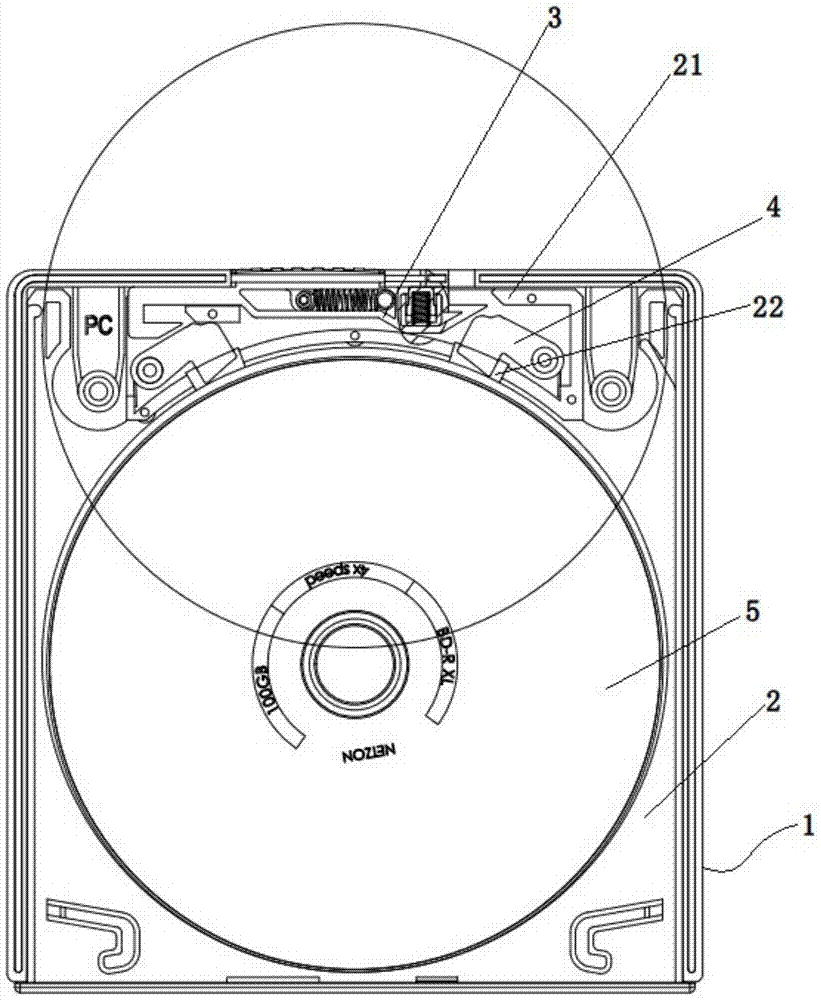

[0026] Example 1: figure 1 It is a schematic exploded view of the structure of the lock type optical disc case provided by the embodiment of the present invention. It can be clearly seen from the figure that the lock type optical disc case provided by this embodiment includes a case body 1 with an opening at the front end and a case body 1 arranged on the case body. The disc tray 2 in 1, the middle part of the disc tray 2 is provided with a coil for supporting the disc 5, and it is characterized in that, the disc tray 2 is provided with a disc clamping part 4, and the disc clamping part 4 is close to The coil, the box body 1 is provided with a tray locker 3, the tray locker can slide between the locked position and the unlocked position, and the tray locker 3 is moved to make it in the locked position , the tray locking member 3 drives the disc clamping member 4 to move toward the coil, so that the optical disc 5 is clamped in the coil, and when the tray locking member 3 is mo...

Embodiment 2

[0034] Embodiment 2: As the best implementation mode of the tray locker 3 in embodiment 1, it is convenient for the tray locker 3 to move between the locked position and the unlocked position, and the tray locker 3 includes a first locker slot 31 and the second locking groove 32, the first elastic member 311 is housed in the first locking groove 31, the second elastic member 321 is housed in the second locking groove 32, and the second elastic member 321 One end is fixedly connected to a locking member 322, and a positioning column 12 is fixedly arranged on the inner side wall of the box body 1, and the positioning column 12 is located in the first locking groove 31, and one end of the first elastic member 311 is connected to the The positioning column 12 is connected, and the other end is fixed on the inner side wall of the first locking groove 31. When the tray locking member 3 is in the unlocked position, the first elastic member 311 does not deform, and the The second elas...

Embodiment 3

[0036] Embodiment 3: Different from Embodiment 1, the disc tray 2 is provided with a limit strip 21 that cooperates with the tray locker 3. When the tray locker 3 is in the locked position, the The tray locker 3 is engaged with the limit bar 21 , and when the tray locker 3 is in the unlocked position, the tray locker 3 is separated from the limit bar 21 . On the one hand, when the tray locking member 3 is engaged with the limiting bar 21, the tray locking member 3 moves between the limiting bar 21 and the disc clamping member 4, and the limiting bar 21 can make the tray The locking member 3 moves smoothly along the limit bar to enhance the pressing force of the tray locking member 3 on the disc clamping member 4; Snapping into the locking groove 13 on the box body can prevent the disc tray 2 from being pulled out from the box body 1, and in addition, the engagement of the tray locking member 3 and the limit bar 21 on the disc tray 2 in this embodiment The cooperation can ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com