A safety valve with high sealing performance

A safety valve and high-sealing technology, applied in the field of safety valves, can solve the problems of unguaranteed safety performance and poor sealing, and achieve the effects of reducing loss, simple structure and ensuring safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

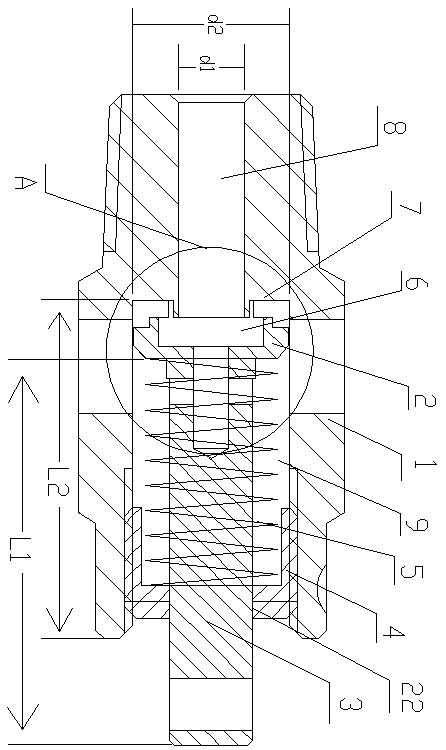

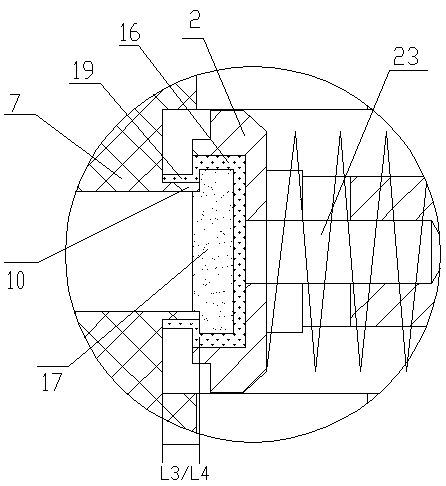

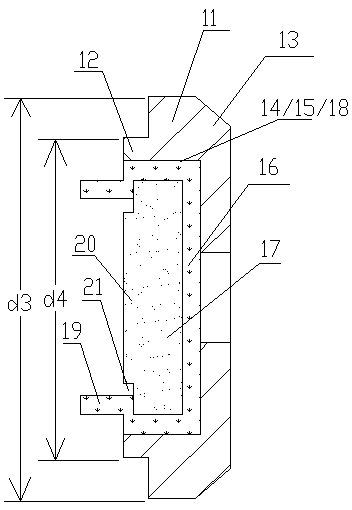

[0015] As shown in the figure, a safety valve with high sealing performance includes a valve body 1, a valve cover 2, a pressure rod 3, a gland 4, a spring 5 and a gasket 6. The valve body 1 is a hollow structure, and the inside of the valve body 1 A circle of first protrusions 7 is provided to separate the main passage 8 and the adjustment chamber 9 in the valve body. The main passage 8 and the adjustment chamber are connected with each other. The inner diameter d1 of the main passage 8 the outer diameter d4 of the jacking part 12, the push-out part 13 is a tapered structure, the valve cover 2 is provided with a gasket fixing cavity 14, and the inner wall of the gasket fixing cavity 14 is provided with an internal thread 15 The gasket 6 includes a first gasket 16 and a second gasket 17, the first gasket 16 is a ring structure, the outside of the first gasket 16 is provided with an external thread 18, and the external thread of the first gasket 16 18 cooperates with the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com