A kind of cashmere fiber weaving carpet and weaving method

A cashmere fiber and carpet technology is applied in the field of textiles, which can solve the problems of rough carpet textiles and weaving methods that do not use cashmere fibers, and achieve the effect of smooth carpet surface and increased income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Embodiment 1: The carpet woven with cashmere fibers described in this embodiment is composed of multiple cashmere yarns, and each cashmere yarn is composed of three cashmere yarns.

specific Embodiment approach 2

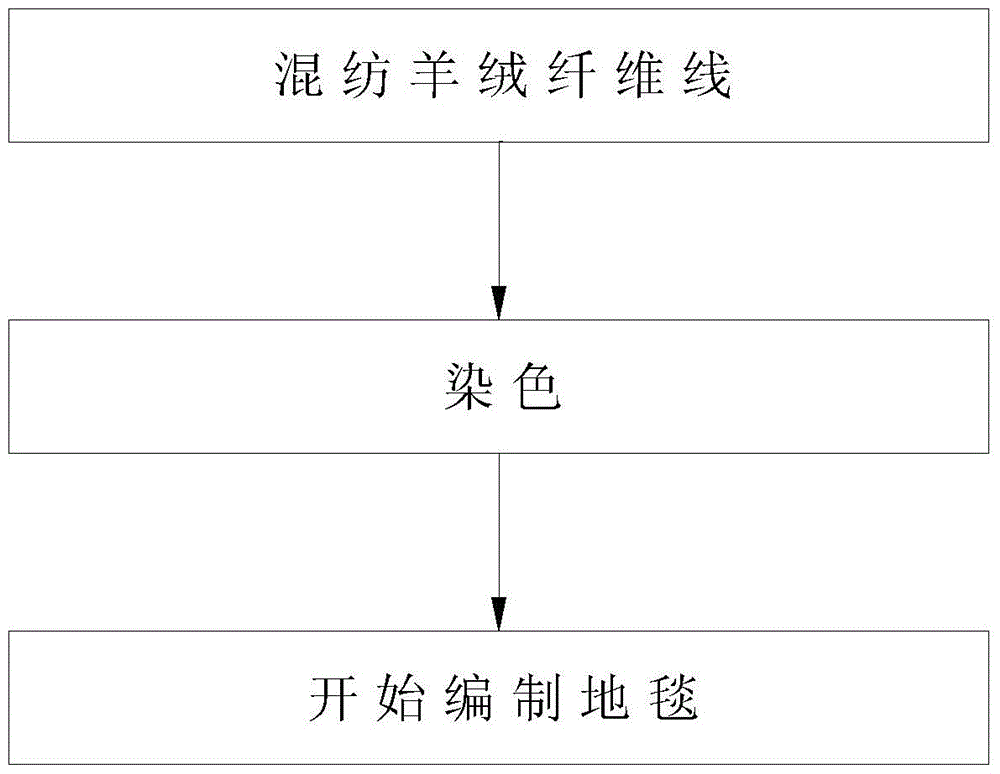

[0029] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment, the specific steps of a kind of sheep fiber weaving carpet weaving method described in this embodiment are as follows:

[0030] Step 1, blending cashmere fiber thread: select cashmere with a length of 32 mm and 20% to 30% wild tussah silk to blend into cashmere fiber thread;

[0031] Step 2, dyeing: dyeing the cashmere fiber thread;

[0032] Step 3. Start weaving the carpet:

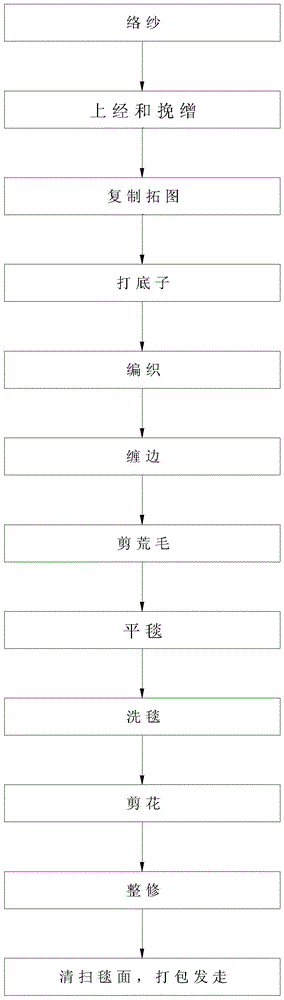

[0033] Step 3 (1), Winding: Ply the yarn through the winder and form a ball;

[0034] Step 3 (2), upper warp and tie: use wire hooks to evenly arrange the cotton yarns on the upper and lower beams of the carpet weaving machine beam to form a curtain-like structure, and tie the buckles;

[0035] Step 3 (3), copying the drawing: copy the blue draft drawing on the point drawing through the light-transmitting desktop;

[0036] Step 3 (4), laying the foundation: use cotton yarn to arrange horizontally a...

specific Embodiment approach 3

[0045] Specific embodiment three: the specific steps of dyeing the cashmere fiber thread in the step 2 of a kind of sheep fiber weaving carpet weaving method described in the present embodiment are as follows:

[0046] Step A, cleaning: use sodium hypochlorite with a concentration not higher than 8%, and soak for 30 minutes at a water temperature of about 30 degrees Celsius;

[0047] Step B, dyeing: water temperature 80-90 degrees Celsius, put in the corresponding pigment and continue heating for 2 hours;

[0048] Step C, color fixation: use a sulfuric acid solution with a concentration not greater than 5%, and the water temperature is about 30 degrees, for 30 minutes;

[0049] Step D, Rinse: Rinse continuously with clean water for about 10 minutes to remove floating color and sulfuric acid residue;

[0050] Step E. Use a dryer to get rid of the main moisture, and then enter the drying room at about 100 degrees Celsius for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com