Horizontal pneumatic tube pressing machine

A tube crimping machine, horizontal technology, applied in the field of wire harness, can solve the problems of undiscovered patent documents, easy to cause industrial accidents, difficult to guarantee quality, etc., and achieve the effect of saving manpower, simple structure and fast crimping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

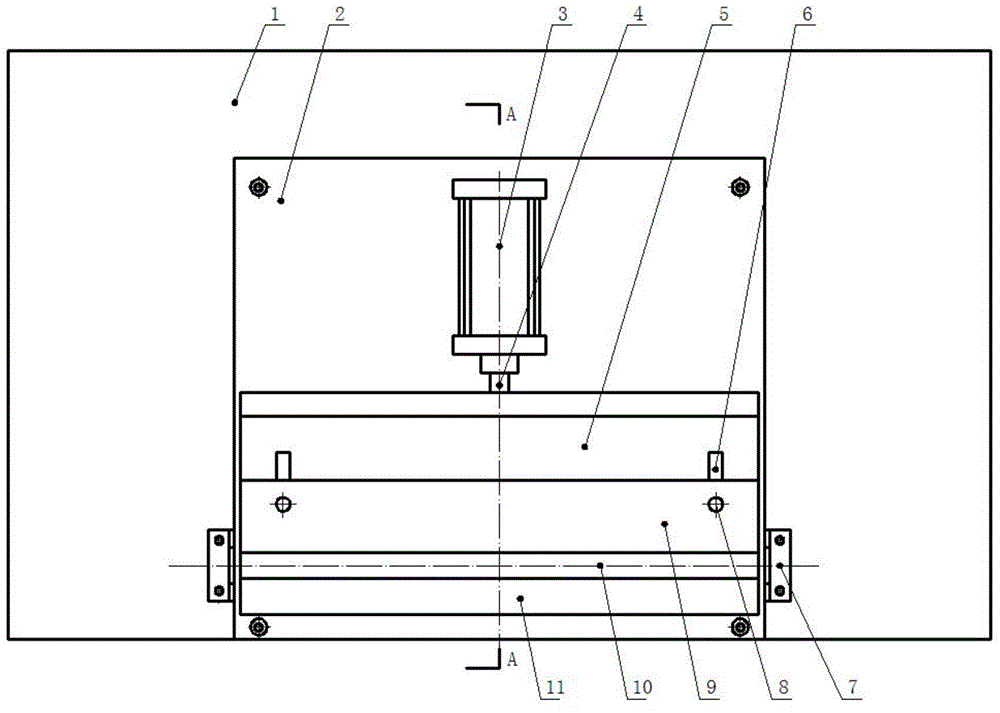

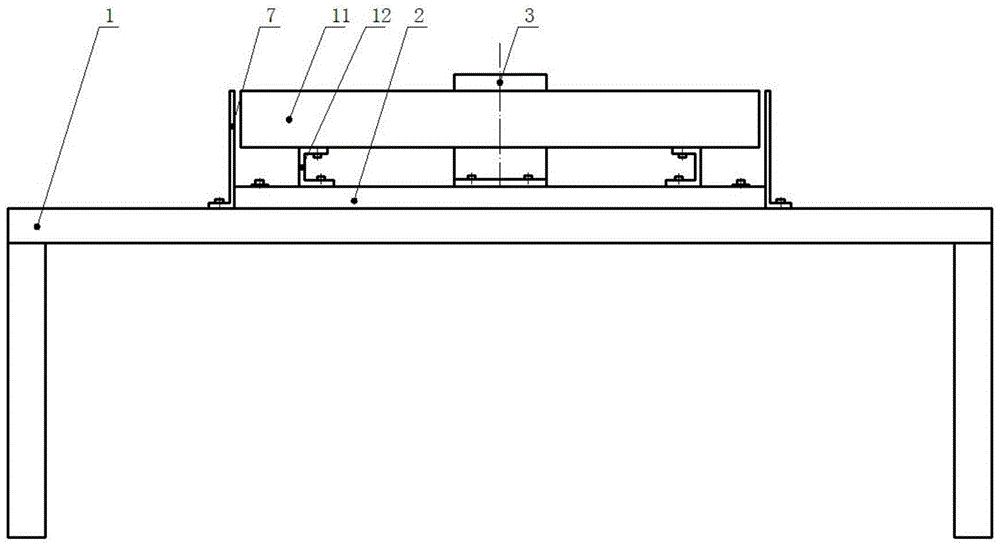

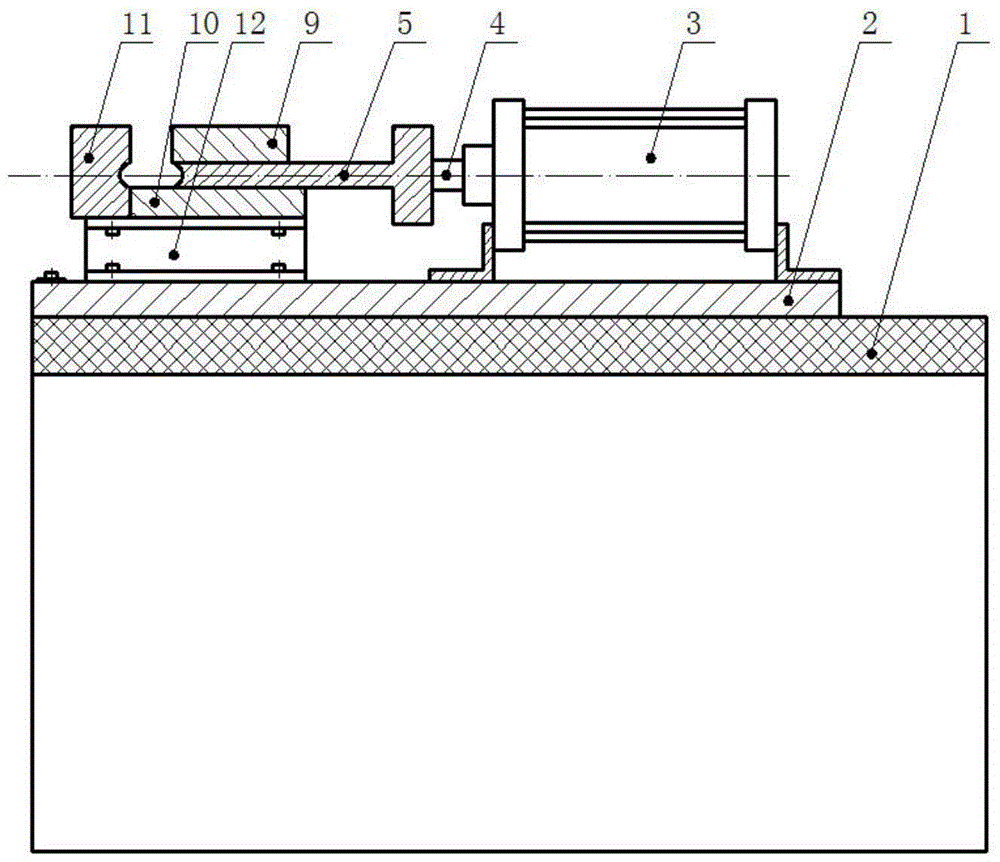

[0015] A horizontal pneumatic tube crimping machine, comprising a workbench 1, a base 2, a cylinder 3, a movable mold 5, a static mold 11, a guide table 10, and an upper press table 9, the base is fixed horizontally on the workbench, and the base is fixed on the base The middle and rear part of the seat is a horizontal fixed cylinder, the front end of the plunger 4 of the cylinder is fixed with the movable mold, and the static mold is fixed on the base corresponding to the front of the movable mold, and the static mold is fixed on the support frame 12 , the support frame is fixed on the base, and a guide table is fixed between the movable mold and the support frame. There are mold cavities (without l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com