Conveying type on-line drying device and drying system with same

A drying device and conveying technology, applied in the directions of drying gas arrangement, drying room/container, drying, etc., can solve the problems of slow drying, low efficiency, uneven drying, etc., achieve easy manufacturing and application promotion, improve production efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

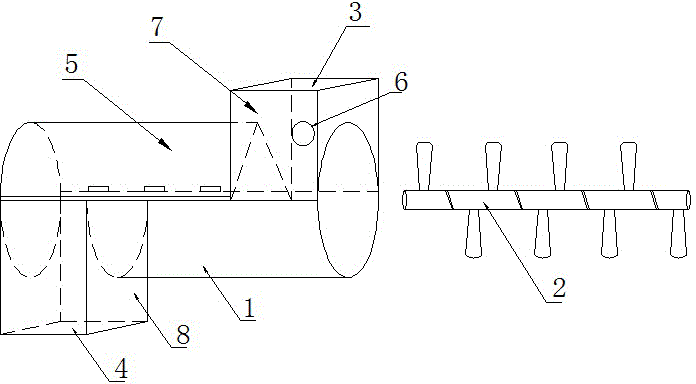

[0018] In order to achieve rapid drying of raw coal, reduce land occupation, improve production efficiency, and reduce production costs, this embodiment provides a figure 1 The conveying type online drying device shown includes a material conveying bin 1, a paddle type conveying shaft 2 placed in the material conveying bin 1, a material inlet 3 arranged at the top of one end of the material conveying bin 1, and a material inlet 3 arranged at the other end of the material conveying bin 1. The material outlet 4 at the bottom of one end, the openable cover 5 arranged on the top of the material delivery bin 1 and the hot air inlet 6 arranged at the material inlet 3; the cover 5 extends from the inner side of the material inlet 3 to the end of the material delivery bin 1 . The bin cover 5 is movably connected with the material conveying bin 1 through a pin shaft or a hinge.

[0019] For crushed raw coal with less water content (moisture content less than 9%), it is not necessary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com