Production control support apparatus and production control support method

A production control and support device technology, applied in the direction of program control, total factory control, electrical program control, etc., can solve the problems of time-consuming calculation and timing delay of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

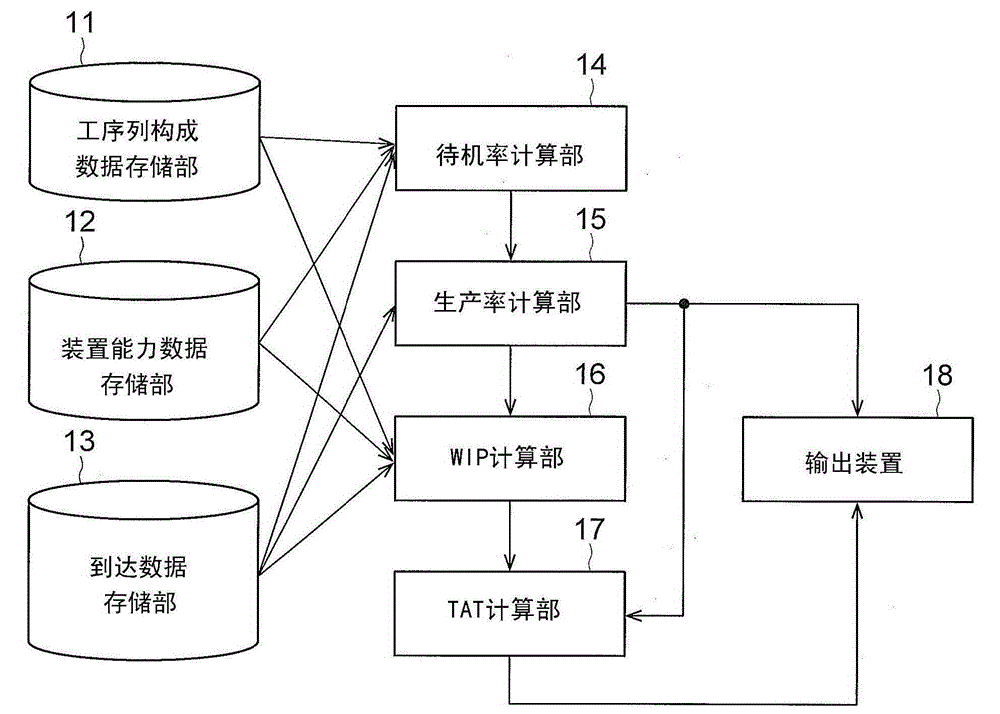

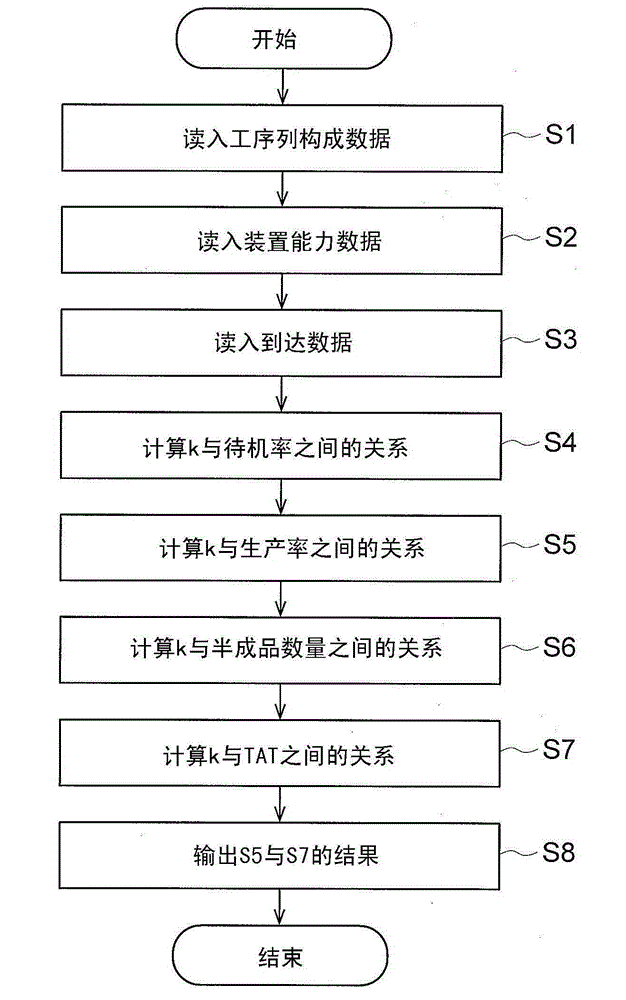

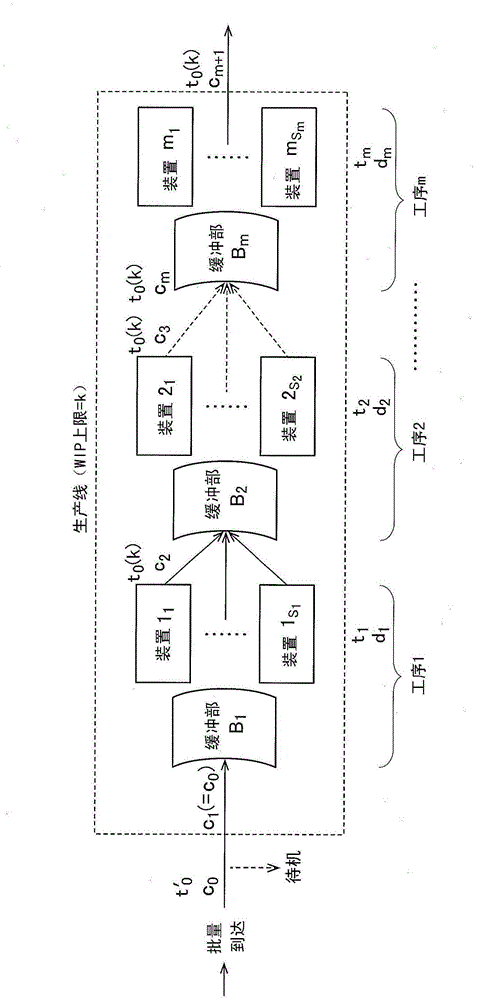

[0016] The production control support device as an embodiment of the present invention is a production control support device for a production line in which a plurality of processes are connected in series, and one process includes: a buffer section for semi-finished products to wait for processing by a processing device; A plurality of processing devices, any one of which processes the semi-finished products waiting in the buffer. The above-mentioned production control support device includes a standby rate calculation unit. For the above-mentioned standby rate calculation part, when an upper limit is set for the number of semi-finished products in the above-mentioned production line, the relationship between the above-mentioned upper limit and the standby rate is calculated. The standby rate refers to: when the number of the above-mentioned semi-finished products reaches The above-mentioned upper limit value is the probability that the above-mentioned semi-finished product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com