Plasma processing device and plasma generating method

一种等离子体、处理设备的技术,应用在离子体产生领域,能够解决变形、功率不会有效地提供等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

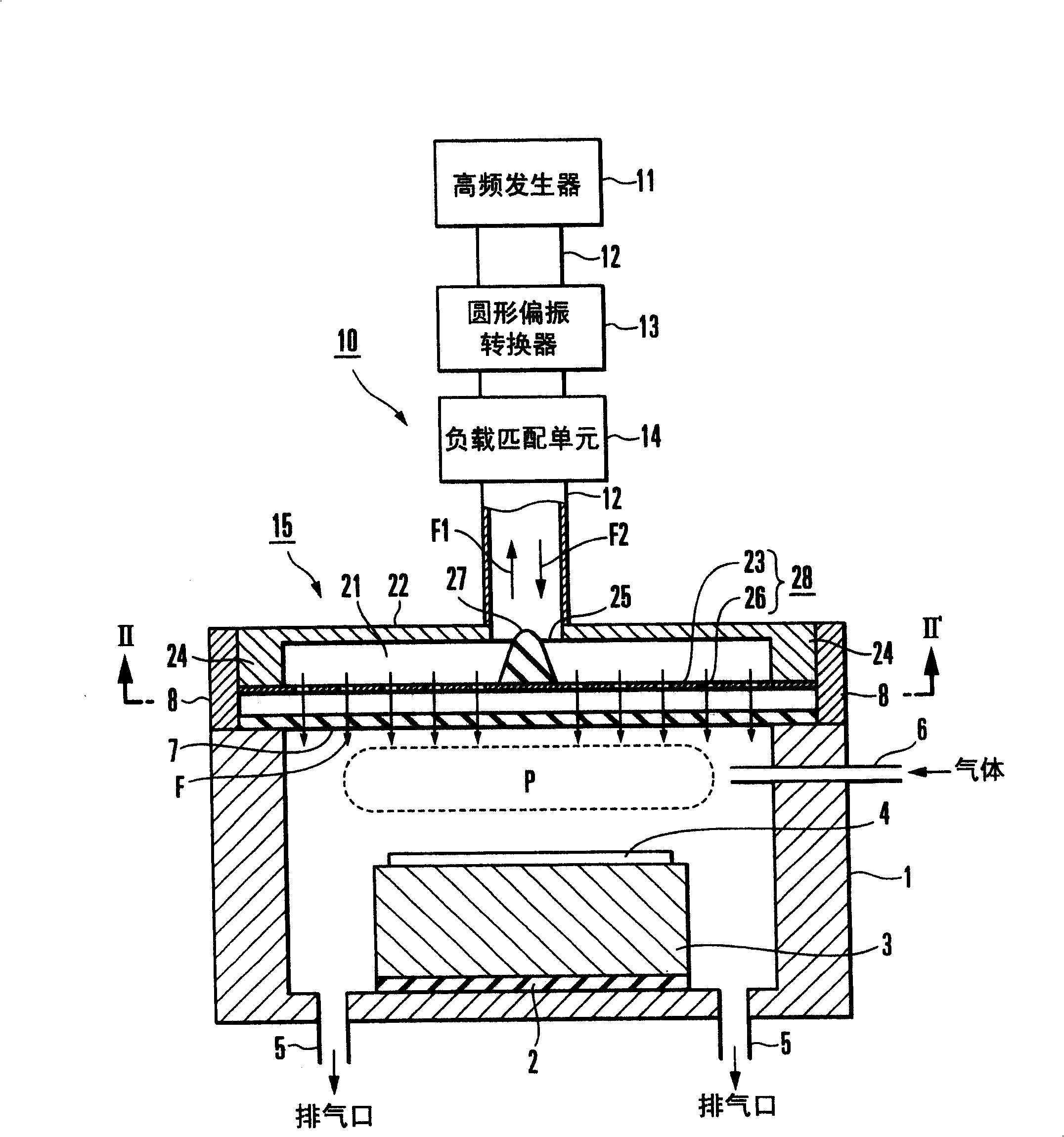

[0032] Attach the reference figure 1 to 4 describe the plasma processing apparatus according to the first embodiment of the present invention. figure 1 is a view showing the general arrangement of the first embodiment. This plasma processing apparatus has a processing container 1 which accommodates a substrate 4 such as a semiconductor or an LCD as a target object and processes the substrate 4 with plasma; and an electromagnetic field supply device 10 which supplies The high-frequency electromagnetic field F is such that plasma P is generated in the processing container 1 by the operation of the high-frequency electromagnetic field F.

[0033]The processing container 1 is a bottomed cylinder with an upper opening. A substrate table (table) 3 is fixed to the center portion of the bottom plane of the processing container 1 via an insulating plate 2 . A substrate 4 is placed on the upper surface of the substrate table 3 .

[0034] An exhaust port 5 for evacuation is formed ...

no. 2 example

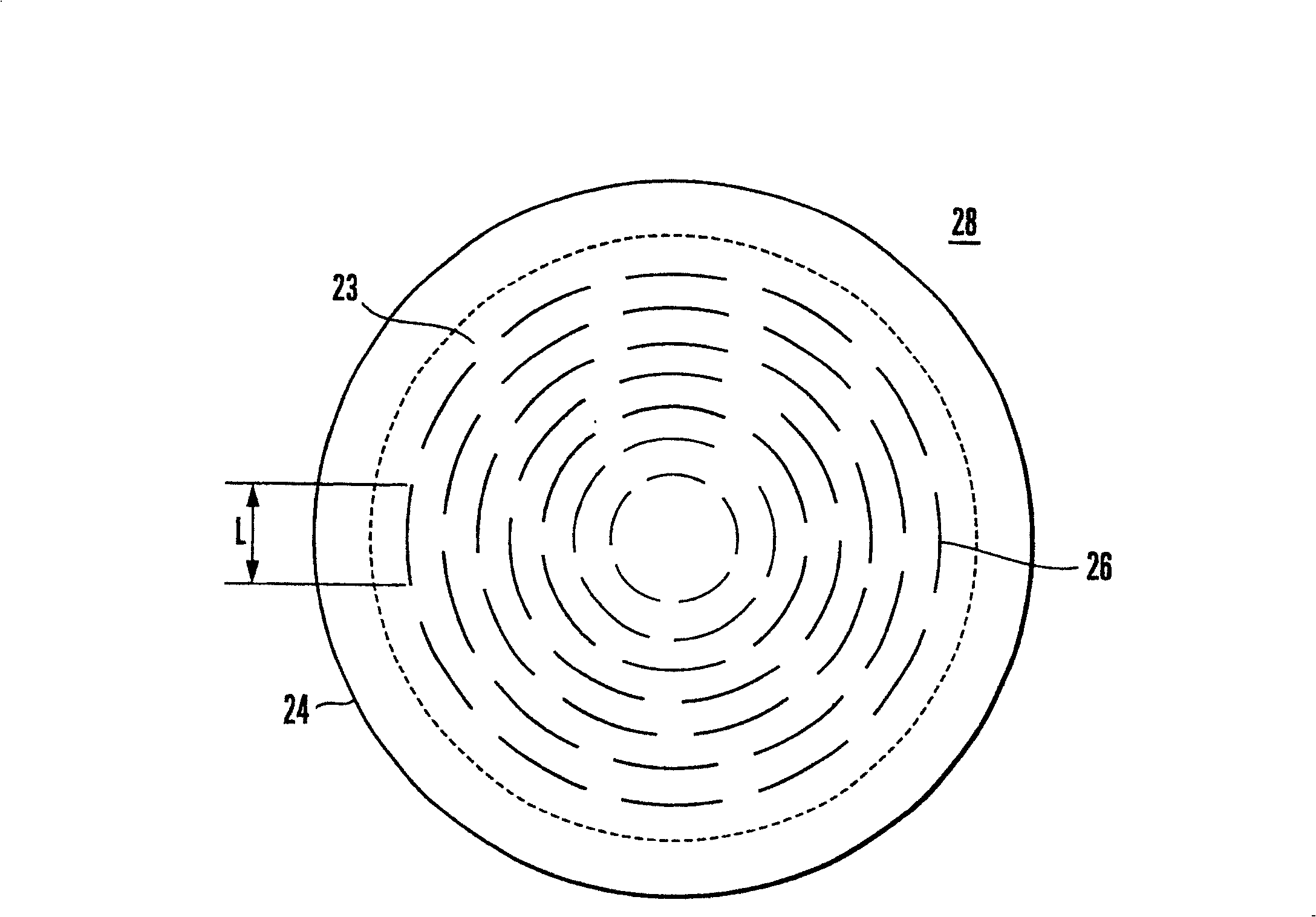

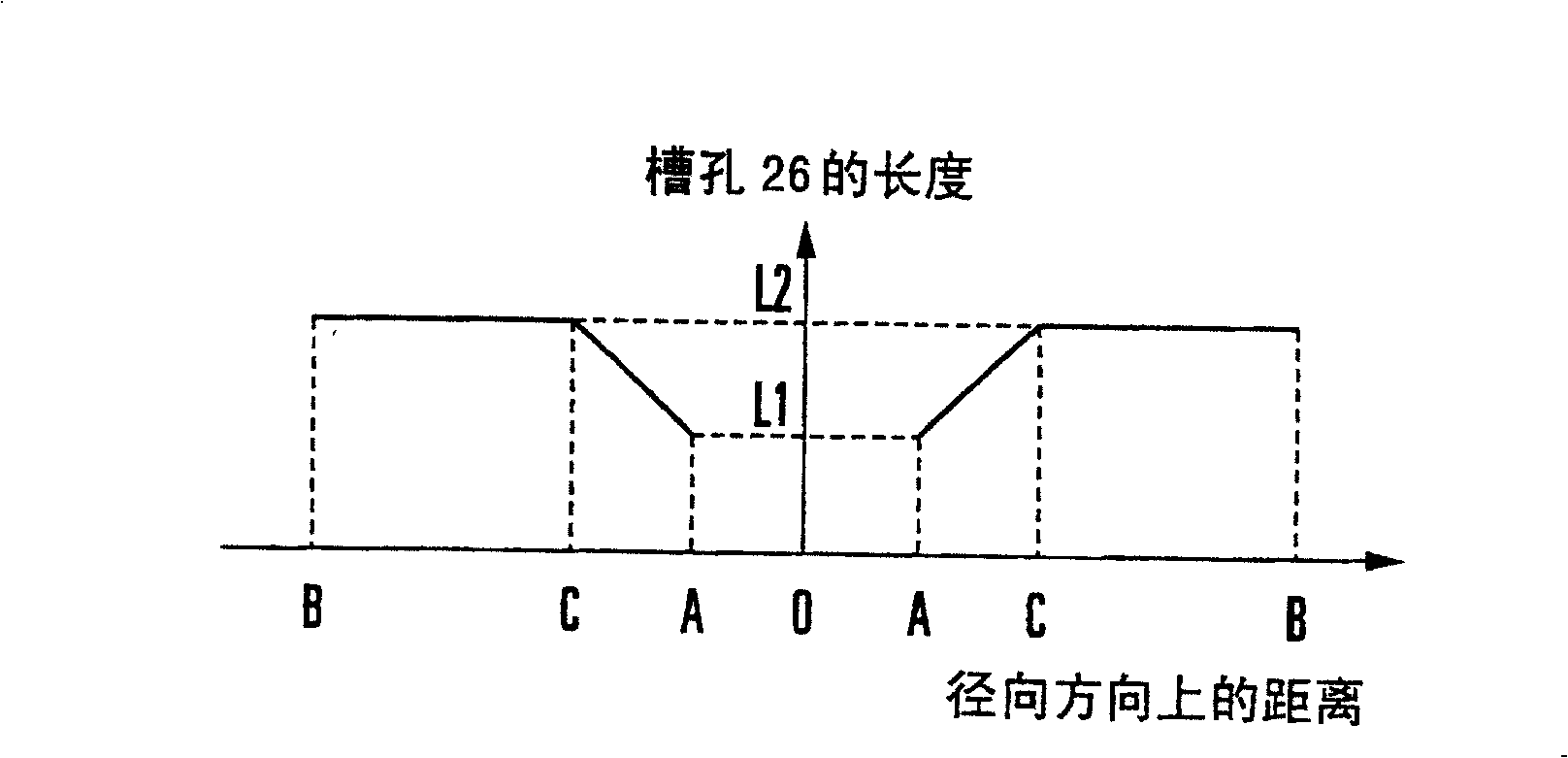

[0064] Attach the reference Figure 5A and 5B A plasma processing apparatus according to a second embodiment of the present invention is described. Figure 5A is a plan view showing the layout of the RLSA antenna surface used in this embodiment; Figure 5B is a graph showing the variation in slot length with respect to the radial direction. exist Figure 5A and 5B in, with Figure 2A and 2B The same or similar parts are denoted by the same reference numerals, and descriptions thereof will be omitted as appropriate. Figure 5A corresponds to Figure 2A .

[0065] As shown in FIG. 5 , it is assumed that a predetermined position on the path from the first middle portion C to the peripheral portion B of the antenna surface 128 (hereinafter will be referred to as a second middle portion) is denoted by D. As shown in FIG. In the radial direction of the antenna surface 128, the length L of the slot 126 increases monotonically from a length L1 at the central portion A, reaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com