Method for reducing vibration of high-pressure compressor and vibration damper used in method

A high-pressure gas machine and vibration damping device technology, which is applied in the field of vibration damping devices to reduce the vibration of high-pressure gas machines, can solve problems such as no guidance plan, and achieve the effects of improving vibration conditions, reducing vibration values, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

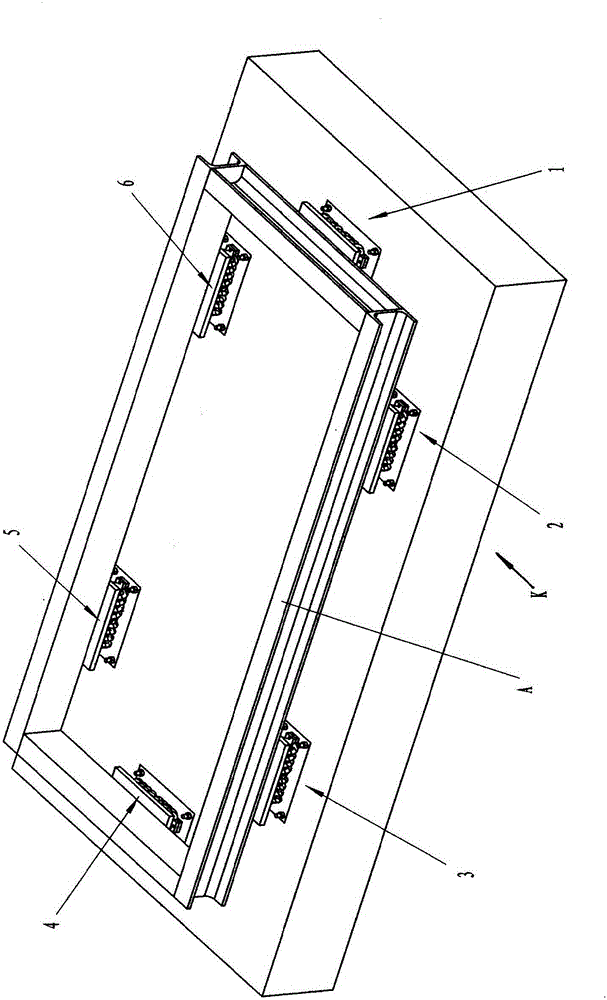

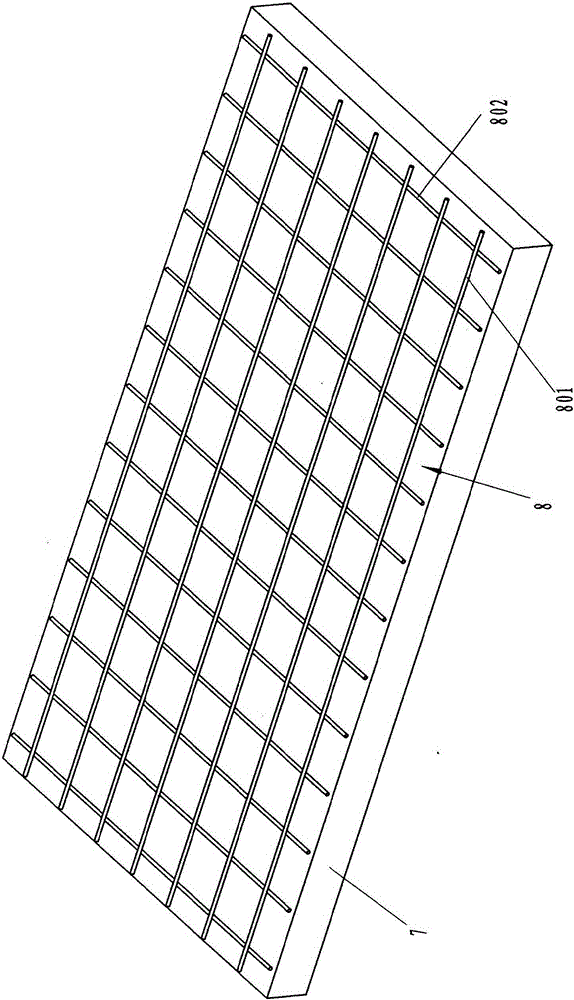

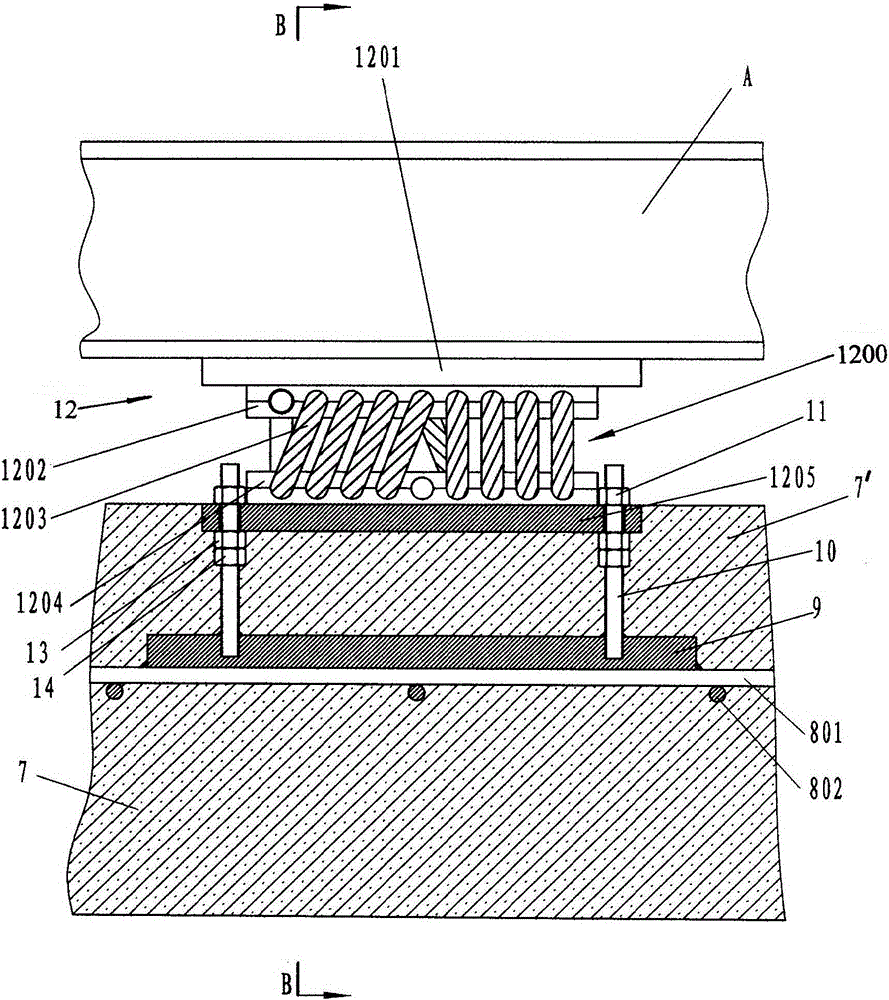

[0023] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 Shown, the damping device that alleviates the vibration of high-pressure gas machine of the present invention has concrete base 7, the steel bar mesh 8 that is positioned at above the concrete base, the first damping (shock) unit 1 that is installed in high-pressure gas machine head one side, The second damping unit 4 installed on the tail side of the high-pressure air machine, the third damping unit 3 and the fourth damping unit 2 installed on the left side (front side) of the high-pressure air machine, and the right side of the high-pressure air machine (rear side) the fifth damping unit 5 and the sixth damping unit 6, the concrete covering layer 7'. The above-mentioned first damping unit, the second damping unit, the third damping unit, the fourth damping unit, the fifth damping unit, and the sixth damping unit have the same structure, and the first damping unit, the second damping unit The damping unit...

Embodiment 2

[0026] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the damping device for alleviating the vibration of the high-pressure air machine of the present invention has a first damping unit 1 installed on one side of the head of the high-pressure air machine, and a second damping unit 4 installed on one side of the tail of the high-pressure air machine. , the third damping unit 3 and the fourth damping unit 2 installed on the left side of the high-pressure air machine, the fifth damping unit 5 and the sixth damping unit 6 installed on the right side of the high-pressure air machine. The above-mentioned first damping unit, the second damping unit, the third damping unit, the fourth damping unit, the fifth damping unit, and the sixth damping unit have the same structure, and the first damping unit, the second damping unit The vibration-damping unit, the third vibration-damping unit, the fourth vibration-damping unit, the fifth vibration-damping unit, and t...

Embodiment 3

[0027] Embodiment 3: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the method for alleviating the vibration of the high-pressure gas machine of the present invention comprises the following steps: 1. make the concrete base 7, namely make the installation foundation, for those with the original installation foundation, remove the original installation foundation (all electrical connections need to be cut off earlier, Remove the external pipeline of the machine), lift the high-pressure air machine from the removal place, and plan the original installation foundation surface of the high-pressure air machine to expose the steel mesh 8; if there is no original installation foundation, it should be made on the ground of the workshop A concrete base 7 is made, and a reinforcement mesh 8 is arranged on the concrete base. Reinforcing bar 8 is made of 7 transverse reinforcing bars 801 arranged horizontally and 13 longitudinal reinforcing bars 802 arranged horizontally. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com