Near Infrared Model Maintenance Method Based on Spectral Projection Discrimination

A spectral projection and near-infrared technology, applied in the field of near-infrared model analysis and evaluation of cigarettes, can solve problems such as unsuitable testing samples, affecting product formula quality, cigarette enterprise losses, etc., to avoid updating maintenance models, and updating management is more scientific , to avoid the effect of misleading production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

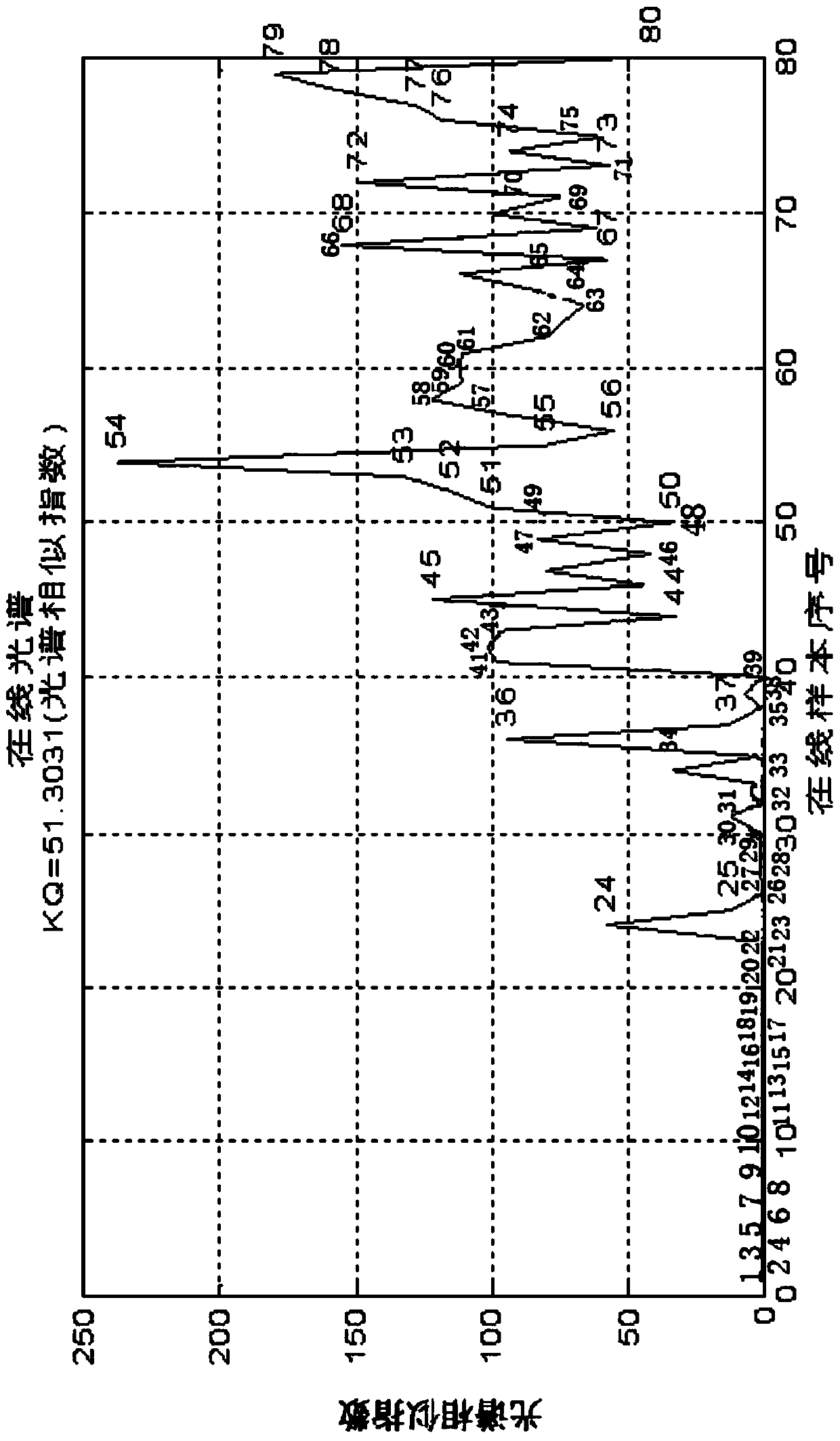

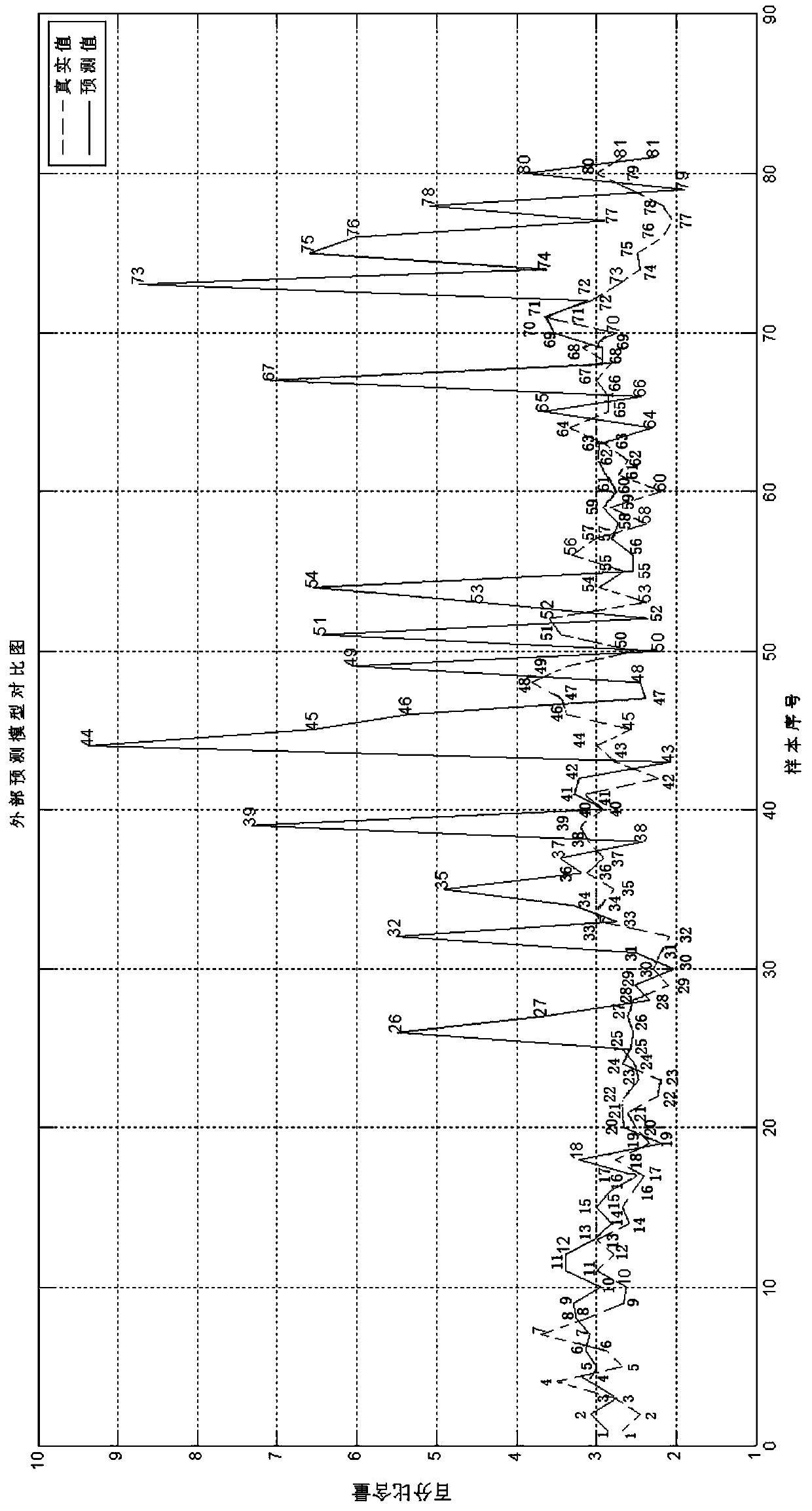

[0025] After the near-infrared modeling is completed, the threshold for model maintenance is calculated based on the predicted sample spectrum, and the difference and similarity measure between the predicted spectrum and the modeling-corrected spectrum are directly calculated to determine whether the near-infrared model needs to be maintained.

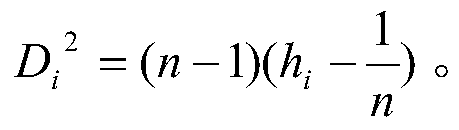

[0026] Step 1. After the near-infrared spectrum model is built, perform the principal component analysis of the near-infrared spectrum on the calibration spectrum in the model, use the principal component spectrum to calculate the Mahalanobis distance of each sample, and judge the sample according to the Mahalanobis distance The abnormal situation; the specific method is: first calculate the Mahalanobis distance, where D i is the Mahalanobis distance of the i-th sample, s i is the principal compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com